Start and stop

Use the buttons to start and stop the pump.Refer to

.

Note:

Standby

Operation at reduced speed will further improve tip seal and bearing service

life. Vacuum performance will be reduced when operating at standby speed.

Push the standby button to select the standby mode. The pump will initially

run at factory default standby speed (75% of full speed).

The Standby button must be pressed to return to normal run speed.

Auto run 1-phase pump

The auto‑run setting congures the pump to start at power‑up without any

customer intervention. This parameter is customer congurable using the

START/STOP buttons. Holding down either the START or STOP button, for

more than eightseconds, will enable or disable the auto‑run setting. The

status of the auto‑run setting is visible via the auto‑run LED.

The pump can be stopped using either manual or parallel control modes

while in auto‑run.

7.3Interface 1-phase pump

7.3.1Digital I/O

The pumps have a 15-pin D-Sub connector located on the user interface

panel. A suitable connector mating half must be used (not supplied) to

connect the pump to the customer control system.

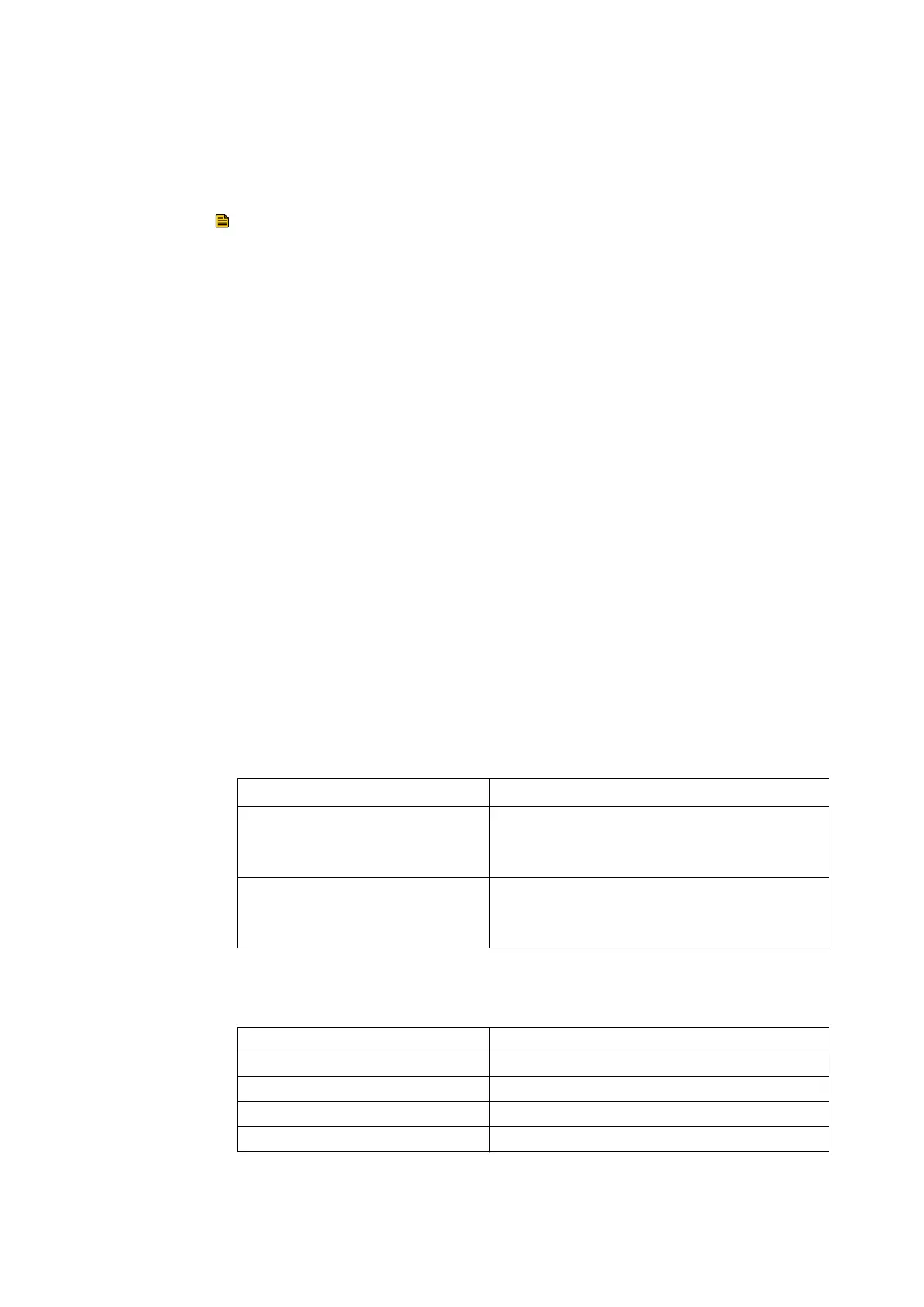

Table 10. Logic interface description

Connector (pump side)

*

15-pin D-Sub (male)

Start and remote enable:

Enable contr

ol voltage: low (closed)

Disable contr

ol voltage: high (open)

0to0.8Vd.c.(I

out

= 0.55mAnominal)

4 ‑ 26.4 V d.c.

(internal pull up to 6.4 Vnominal)

Standby control input:

Enable control voltage: low (closed)

Disable control voltage: high (open)

0 to 0.8 V d.c. (l

OUT

= 0.3 mA nominal)

4 ‑ 26.4 V d.c.

(internal pull up to 3.2 V nominal)

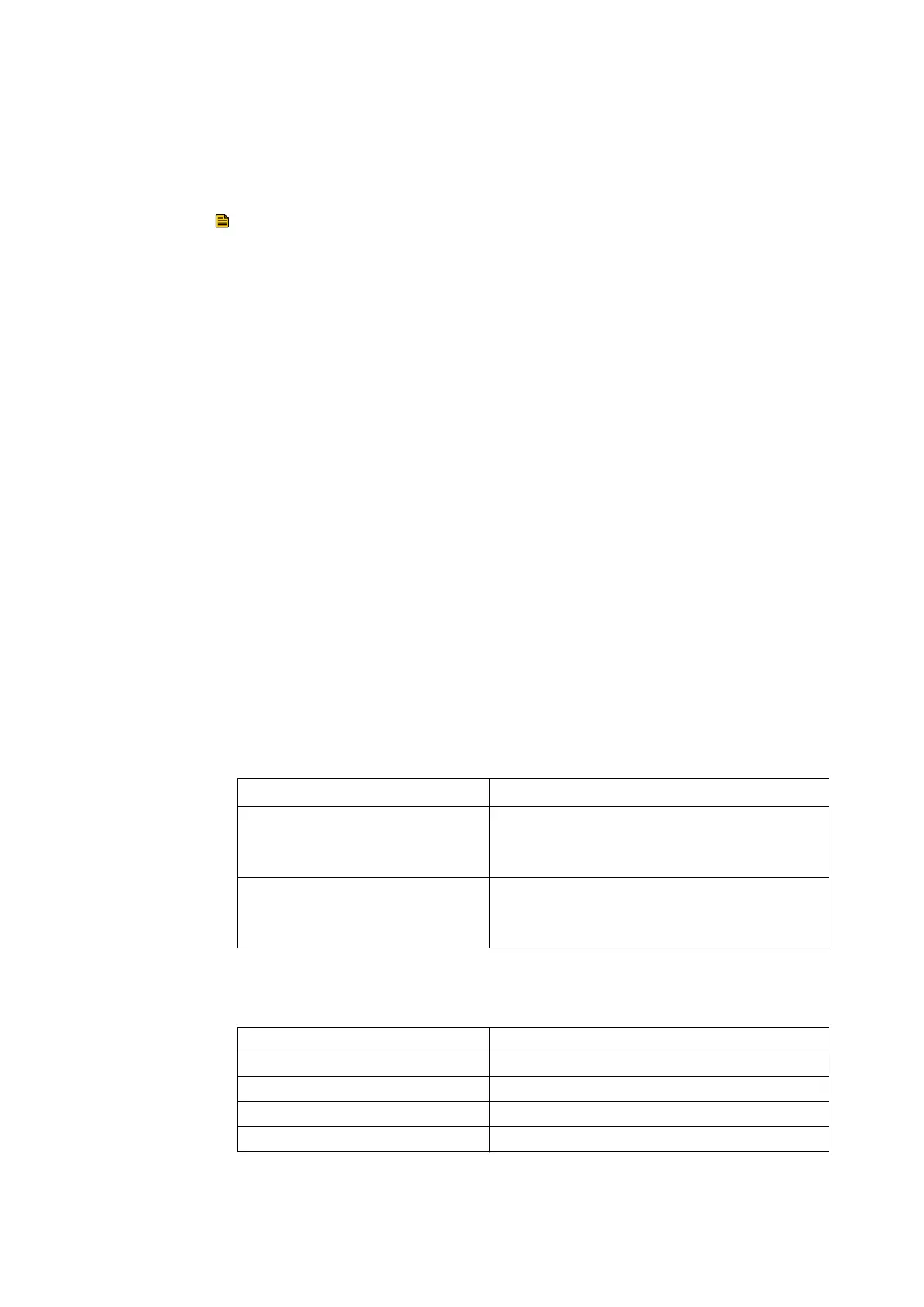

Table 11. NORMAL status output:

Type Open collector transistor plus pull up resistor.

< Normal speed (default 80%) OFF (4.7 k pull up + diode to 12 V d.c.)

³ Normal speed ON (< 0.8 V d.c. sinking 10 mA)

Maximum current rating 10 mA

Maximum voltage rating 28.8 V d.c.

38 300668736_002_C7 - © Leybold

Operation

Loading...

Loading...