The pump is designed to require little user maintenance. Observe the

following guidelines when carrying out maintenance on the pump:

▪ Make sure the maintenance is done by a suitably trained and supervised▪

technician. Obey local and national safety requirements.

▪ Make sure the maintenance technician is familiar with the safety▪

procedures which relate to the products processed by the pumping

system.

▪ Check that all the required parts are available and are of the correct type▪

before starting work.

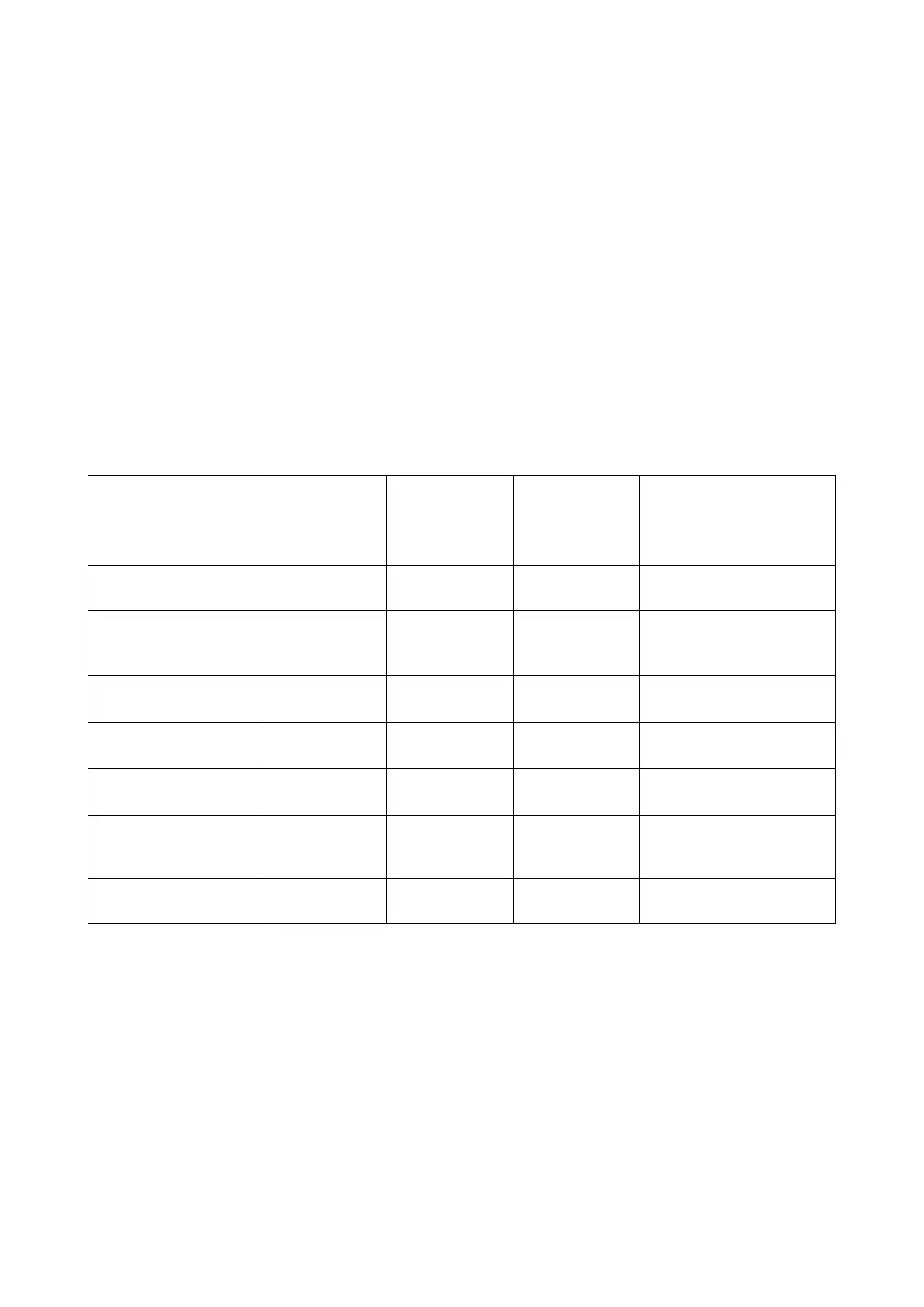

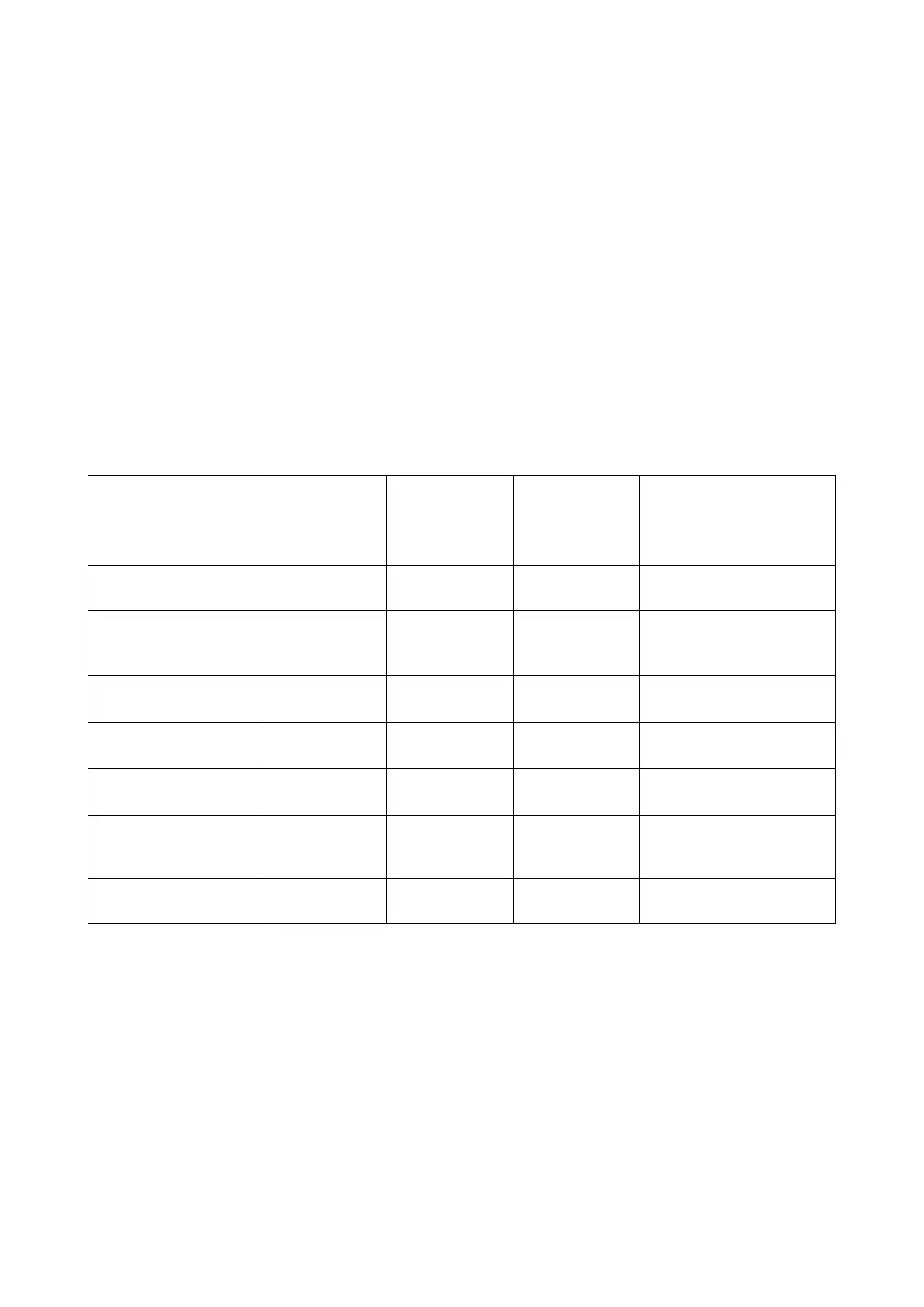

9.2Maintenance plan

More frequent maintenance may be required if the pump is used to pump

aggressive gases or vapours, such as solvents, organic substances and

acids, or if the pump is operated continuously at the higher end of its

operating temperature.

Table 18 Maintenance plan

Operation

Frequency

(months)

Service

indicator

1-phase

Hours

indicators

1-phase

3-phase

Section

reference

Inspect and clean the

inlet strainer

12 No 8760

on page 57

Inspect and clean the

external fan cover if

required

12 No 8760

on page 58

Check the pump

performance

30 Yes 21900

on page 58

Replace the tip-seal

30 or when

needed

Yes 21900

on

page 58

Replace the pump

bearings

60 Yes 43800

on page 58

Replace the pump

controller

120 Yes 87600

on page 59

Electrical safety check 60 No 43800

on

page 60

9.3Inspect and clean the inlet strainer

Whenever the pump is disconnected from the vacuum system, or on an

annual basis, we recommend:

▪ Removing the inlet strainer from the pump inlet and remove any debris▪

that may have accumulated. Refer to

.

▪ Inspecting the inlet strainer and if necessary, clean it with a cleaning▪

solution suitable for the substances pumped. Ret the inlet strainer

before reconnecting the pump to the vacuum system. Refer to

on page 28.

300668736_002_C7 - © Leybold 57

Maintenance

Loading...

Loading...