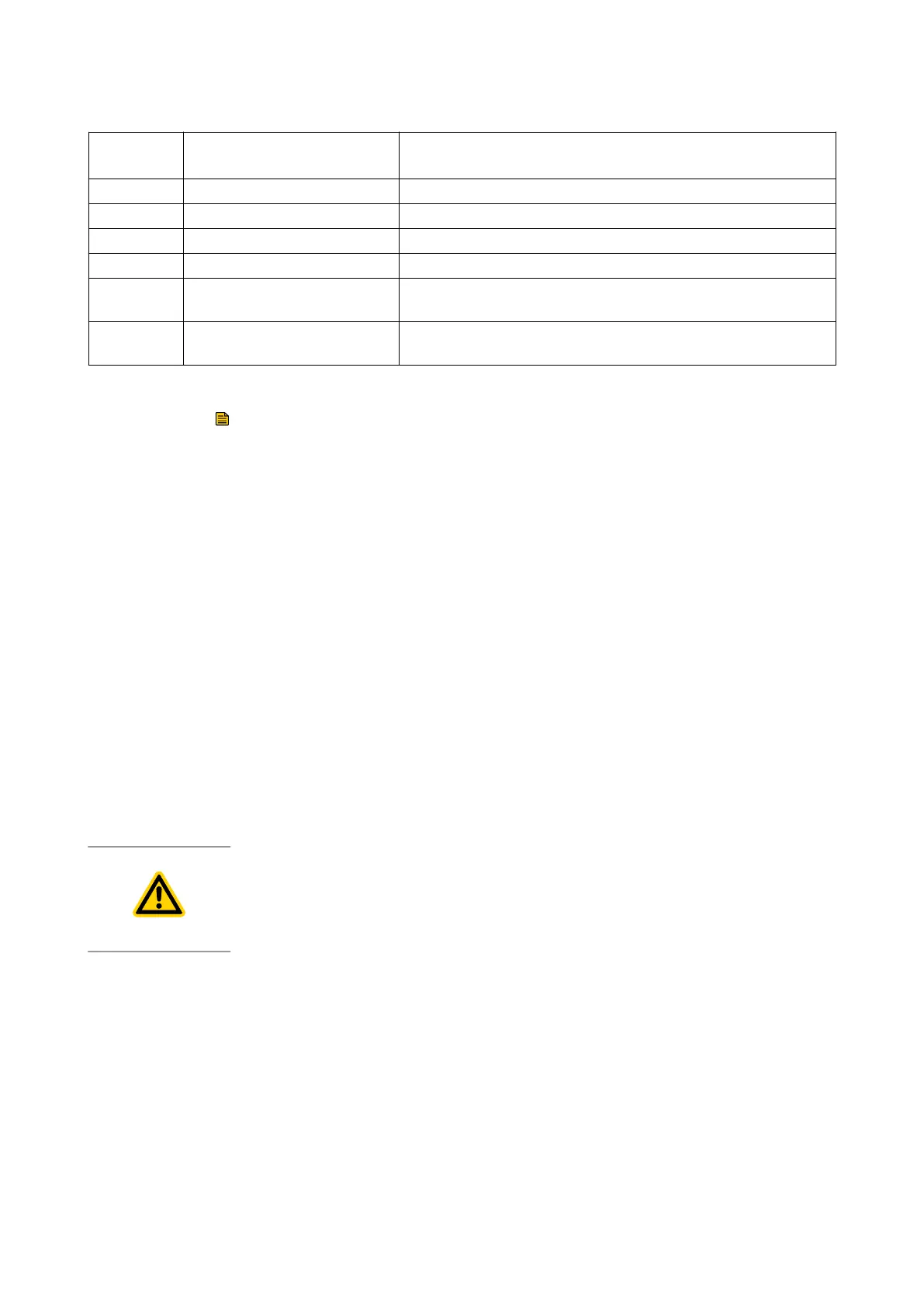

Pin

number

Signal Use

10 Chassis/Screen Screen

11 Not connected Unused control pin

12 Chassis/Screen Screen

13 Not connected Unused control pin

14 REMOTE-Control Input

Connect to pin 2 (0 V) to enable remote control via Parallel

control mode

15 NORMAL-Status Output

Logic LOW when the pump r

otational speed is at normal speed

or above.

7.3.3Remote control and monitoring

Note:

Connect the control equipment to the control input pins of the logic interface

mating half. The control inputs are as follows:

▪ Start▪

▪ Standby speed▪

To activate any of these control inputs, connect the relevant control input

(pin 14) to the (0 V) control reference.

To monitor the normal status output, connect the control equipment to the

Normal status output (pin15) and to (pin2) of the logic interface mating half.

The output can be used to control other devices in the pumping system.

The output can drive a low power relay of up to 24V coil rating (up to

10mA).

To monitor the fail status output, connect the control equipment to the fail

output (pin 7) and to (pin 2) of the logic interface mating half. The output

can be used to control other devices in the pumping system. The output can

drive a low power relay of up to 24 V coil rating (up to 10 mA).

7.4Manual operation 3-phase pump

CAUTION: PUMP DAMAGE

Do not run the pump at frequencies above 65 Hz as this could cause damage to

the pump.

The 3-phase pump is a direct-on-line pump application with no speed

control. The pump running speed is determined by the electrical frequency

of the customer’s supply, i.e. 50 Hz or 60 Hz. Refer to

.

The pump will start as soon as power is applied.

7.5Use of a gas ballast control 1 and 3-phase pump

The gas ballast control can be used to optimise the performance of the

pump for the application. The position of the gas ballast control can be

changed when the pump is either off or operating.

40 300668736_002_C7 - © Leybold

Operation

Loading...

Loading...