'XHWRRXUSROLF\RIFRQWLQXRXVSURGXFWLQQRYDWLRQVRPHVSHFL¿FDWLRQVPD\FKDQJHZLWKRXWQRWL¿FDWLRQ

©

/*(OHFWURQLFV86$,QF(QJOHZRRG&OLIIV1-$OOULJKWVUHVHUYHG³/*´LVDUHJLVWHUHGWUDGHPDUNRI/*&RUS

5()5,*(5$17'(6,*1 | 139

Refrigerant Piping Design & Layout Best Practices

LAYOUT BEST PRACTICES

Selecting Field-Supplied Copper Tubing

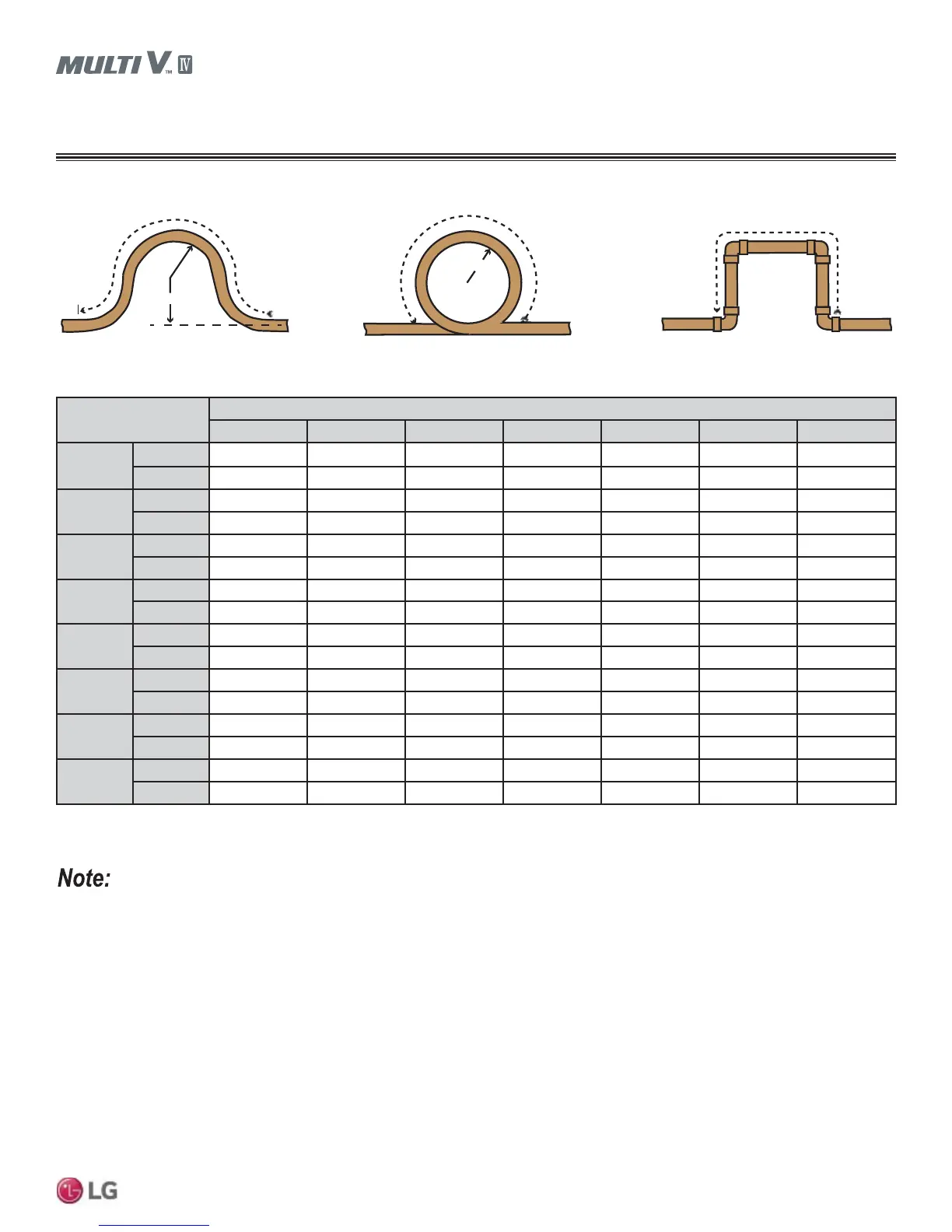

Anticipated Linear

Expansion (LE) (inches)

Nominal Tube Size (OD) inches

1/4 3/8 1/2 3/4 1 1-1/4 1-1/2

1/2

R

1

6789111213

L

2

38 44 50 59 67 74 80

1

R

1

9 101113151718

L

2

54 63 70 83 94 104 113

1-1/2

R

1

11 12 14 16 18 20 22

L

2

66 77 86 101 115 127 138

2

R

1

12 14 16 19 21 23 25

L

2

77 89 99 117 133 147 160

2-1/2

R

1

14 16 18 21 24 26 29

L

2

86 99 111 131 149 165 179

3

R

1

15 17 19 23 26 29 31

L

2

94 109 122 143 163 180 196

3-1/2

R

1

16 19 21 25 28 31 34

L

2

102 117 131 155 176 195 212

4

R

1

17 20 22 26 30 33 36

L

2

109 126 140 166 188 208 226

1

R = Centerline Length of Pipe.

2

L = Centerline Minimum Radius (inches).

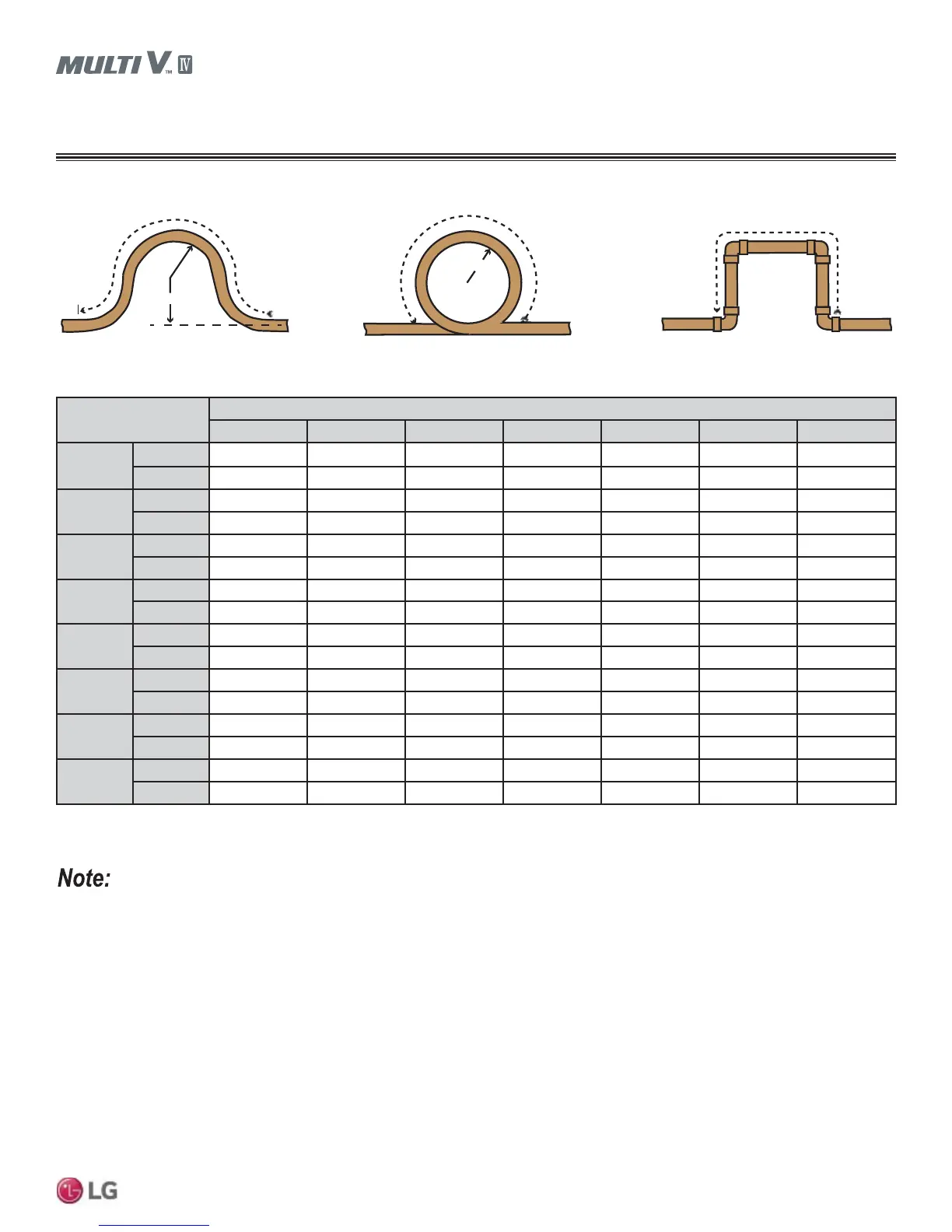

Figure 27: Coiled Expansion Loops and Offsets (Plan View).

Table 53: Radii of Coiled Expansion Loops and Developed Lengths of Expansion Offsets.

Large Tubing U-bend (>3/4 in.) Loop Small Tubing U-bend (<3/4 in.)

R

L

R

L

L

All expansion Loops and Offsets should be installed in the horizontal plane to prevent the possibility of trapping oil. Loops and Offsets in verti-

cal risers should also be installed in a horizontal plane.

Loading...

Loading...