PRODUCT DATA | 11

Product Data

'XHWRRXUSROLF\RIFRQWLQXRXVSURGXFWLQQRYDWLRQVRPHVSHFL¿FDWLRQVPD\FKDQJHZLWKRXWQRWL¿FDWLRQ

©

/*(OHFWURQLFV86$,QF(QJOHZRRG&OLIIV1-$OOULJKWVUHVHUYHG³/*´LVDUHJLVWHUHGWUDGHPDUNRI/*&RUS

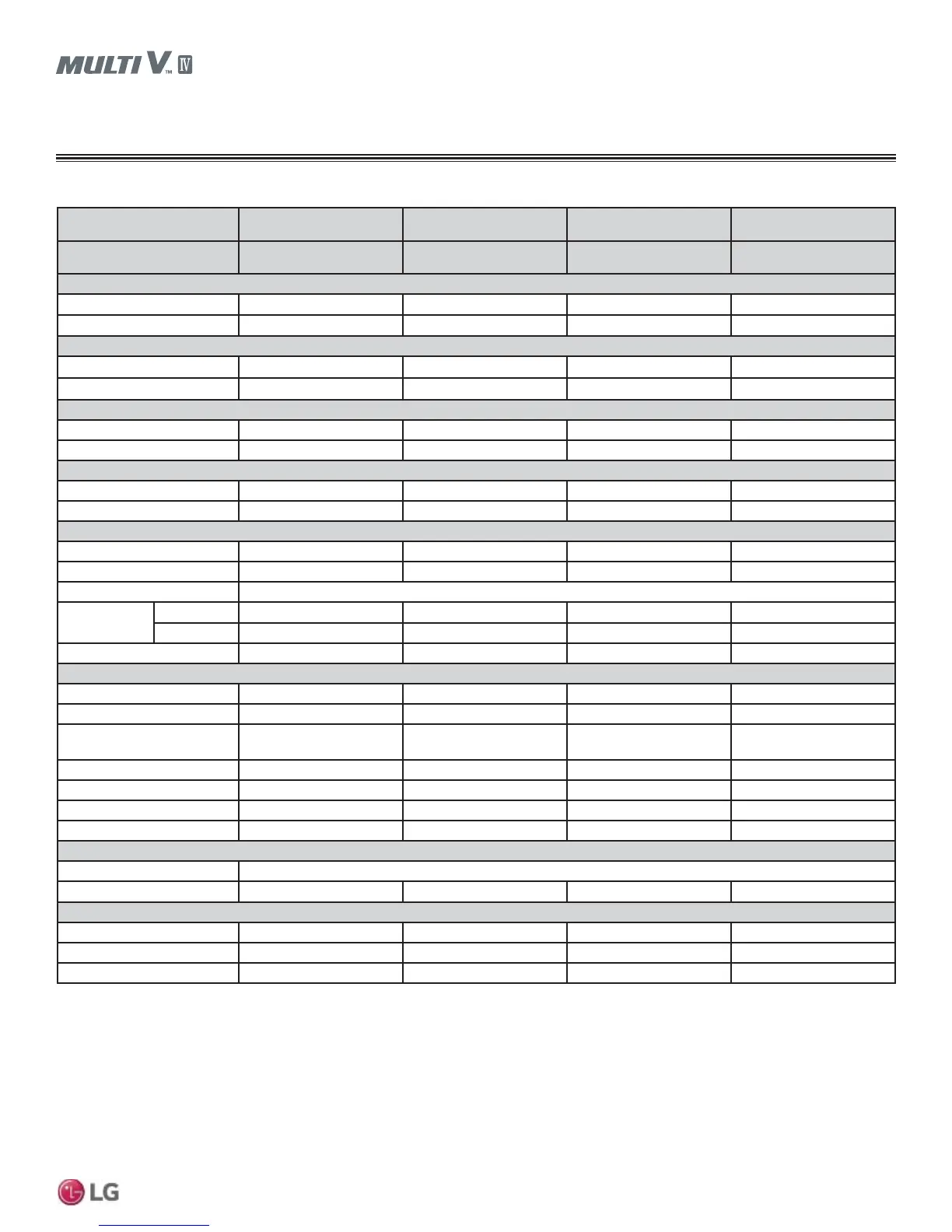

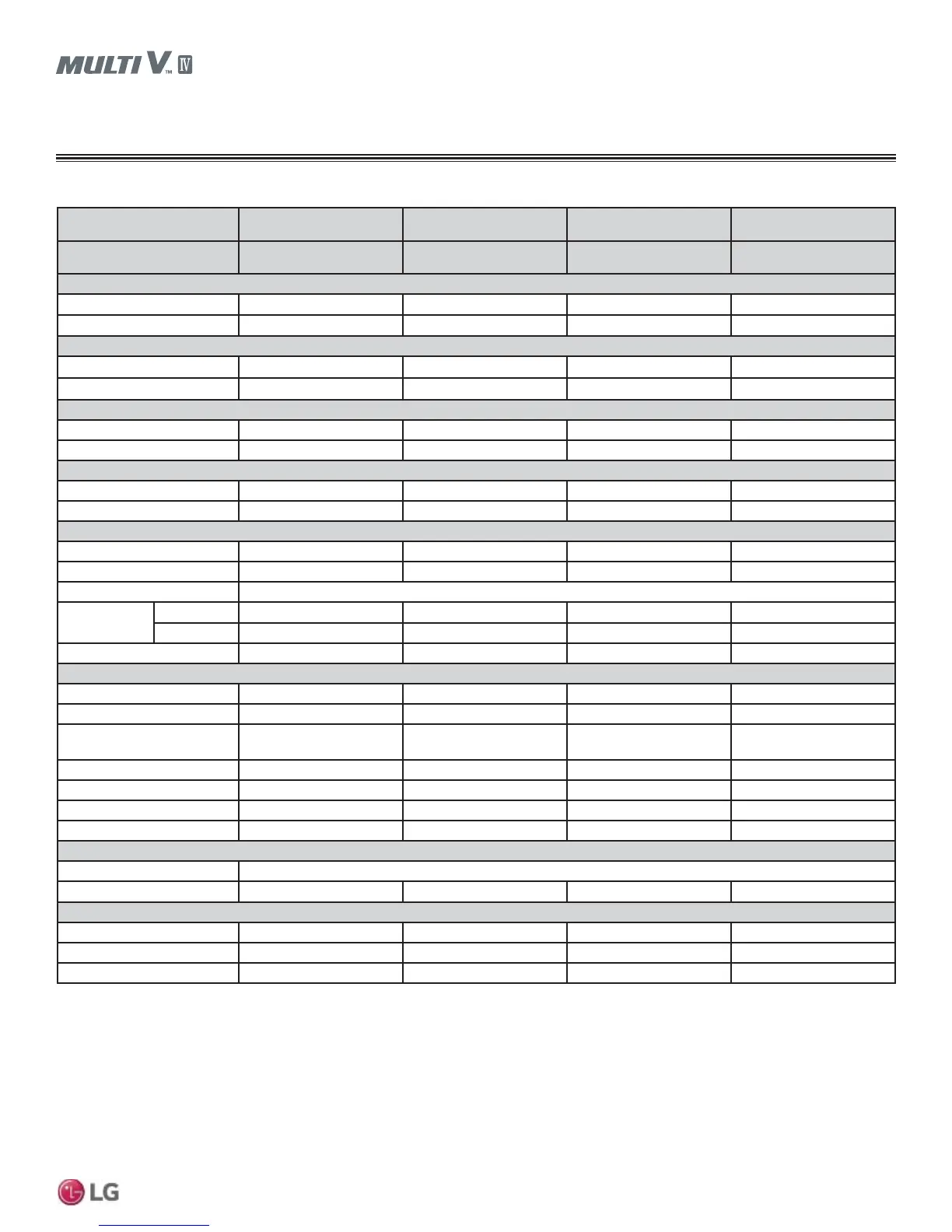

Table 2: Dual-Frame 208-230V Heat Pump Units.

Combination Unit Model

Number

16.0 Ton

ARUN192BTE4

18.0 Ton

ARUN216BTE4

20.0 Ton

ARUN240BTE4

22.0 Ton

ARUN264BTE4

Individual Component Model

Numbers

ARUN072BTE4 +

ARUN121BTE4

ARUN072BTE4 +

ARUN144BTE4

ARUN096TE4 +

ARUN144BTE4

ARUN121BTE4 +

ARUN144BTE4

Cooling Performance

Nominal Cooling Cap. (Btu/h)

1

192,000 216,000 240,000 264,000

Rated Cooling Cap. (Btu/h)

2

184,000 206,000 228,000 250,000

Heating Performance

Nominal Heating Cap. (Btu/h)

1

216,000 243,000 270,000 297,000

Rated Heating Cap. (Btu/h)

2

206,000 230,000 256,000 282,000

Operating Range

Cooling (°F DB)

3

14 to 122 14 to 122 14 to 122 14 to 122

Heating (°F WB)

-13 to +61 -13 to +61 -13 to +61 -13 to +61

Compressor

Inverter Quantity

HSS DC Scroll x 2 HSS DC Scroll x 3 HSS DC Scroll x 3 HSS DC Scroll x 3

Oil/Type

PVE/FVC68D PVE/FVC68D PVE/FVC68D PVE/FVC68D

Fan (Top Discharge)

Type

Propeller (BLDC) Propeller (BLDC) Propeller (BLDC) Propeller (BLDC)

Motor Output (kW) x Qty.

0.75 + 0.60 x 2 0.75 + 0.60 x 2 0.60 x 2 + 0.60 x 2 0.60 x 2 + 0.60 x 2

Motor/Drive

Brushless Digitally Controlled/Direct

Oper. Range

(RPM)

Cooling

0 - 1,050 0 - 1,100 0 - 1,100 0 - 1,100

Heating

80 - 1,050 80 - 1,100 80 - 1,100 80 - 1,100

Maximum Air Volume (CFM)

17,250 17,600 20,050 20,050

Unit Data

Refrigerant Type

R410A R410A R410A R410A

Refrigerant Control/Location

EEV/Indoor Unit EEV/Indoor Unit EEV/Indoor Unit EEV/Indoor Unit

Min. to Max. No. Indoor Units/

System

4

1 - 32 1 - 35 1 - 39 1 - 42

Sound Pressure dB(A)

5

61.8 62.0 62.3 62.3

Net Unit Weight (lbs.)

430 + 540 430 + 628 540 + 628 540 + 628

Shipping Weight (lbs.)

452 + 573 452 + 661 573 + 661 573 + 661

Communication Cables

6,7

2 x 18 2 x 18 2 x 18 2 x 18

Heat Exchanger

Material and Fin Coating

Copper Tube/Aluminum Fin and GoldFin™/Hydrophilic

Rows/Fins per inch

3/14 3/14 3/14 3/14

Piping

8

Liquid Line Conn. (in., OD)

3/8 + 1/2 Braze 3/8 + 1/2 Braze 3/8 + 1/2 Braze 1/2 + 1/2 Braze

Vapor Line Conn. (in., OD)

3/4 + 1-1/8 Braze 3/4 + 1-1/8 Braze 7/8 + 1-1/8 Braze 1-1/8 + 1-1/8 Braze

Factory Charge lbs. of R410A

16.9 + 23.6 16.9 + 23.6 23.6 + 23.6 23.6 + 23.6

GENERAL DATA

$5816HULHV+HDW3XPS2XWGRRU8QLW6SHFL¿FDWLRQV

1

Nominal capacity applied with non-ducted indoor units, and is rated 0 ft. above sea level with 25 ft.

of refrigerant line per indoor unit and a 0 ft. level difference between outdoor and indoor units. All capaci-

ties are net with a Combination Ratio between 95–105%.

Nominal cooling capacity rating obtained with air entering the indoor unit at 80ºF dry bulb (DB) and 67ºF

wet bulb (WB) and outdoor ambient conditions of 95ºF dry bulb (DB) and 75ºF wet bulb (WB).

Nominal heating capacity rating obtained with air entering the indoor unit at 70ºF dry bulb (DB) and

59ºF wet bulb (WB) and outdoor ambient conditions of 47ºF dry bulb (DB) and 43ºF wet bulb (WB).

2

Rated capacity is certified under AHRI Standard 1230. See www.ahrinet.org for information.

3

Cooling range with Low Ambient Baffle Kit (sold separately) is -9.9°F to +122°F.

4

The System Combination Ratio must be between 50–130%.

5

Sound pressure levels are tested in an anechoic chamber under ISO Standard 3745.

6

All communication cable to be minimum 18 AWG, 2-conductor, stranded, shielded, and must comply

with applicable local and national codes. Ensure the communication cable is properly grounded at the

master unit only. Do not ground the ODU-IDU communication cable at any other point.

7

Power wiring cable is field provided and must comply with the applicable local and national codes. See

page 31 for detailed electrical data.

8

Refer to the Refrigerant Piping section of this manual for correct line sizing. Contractor must use LG

manufactured Y-Branch and Header Kits only. Designer must verify refrigerant piping design configura-

tion using LG’s computerized refrigerant piping (LATS Multi V) software to validate the pipe design.

Loading...

Loading...