CHAPTER 8: OPERATION 8-15

ALPHA 552

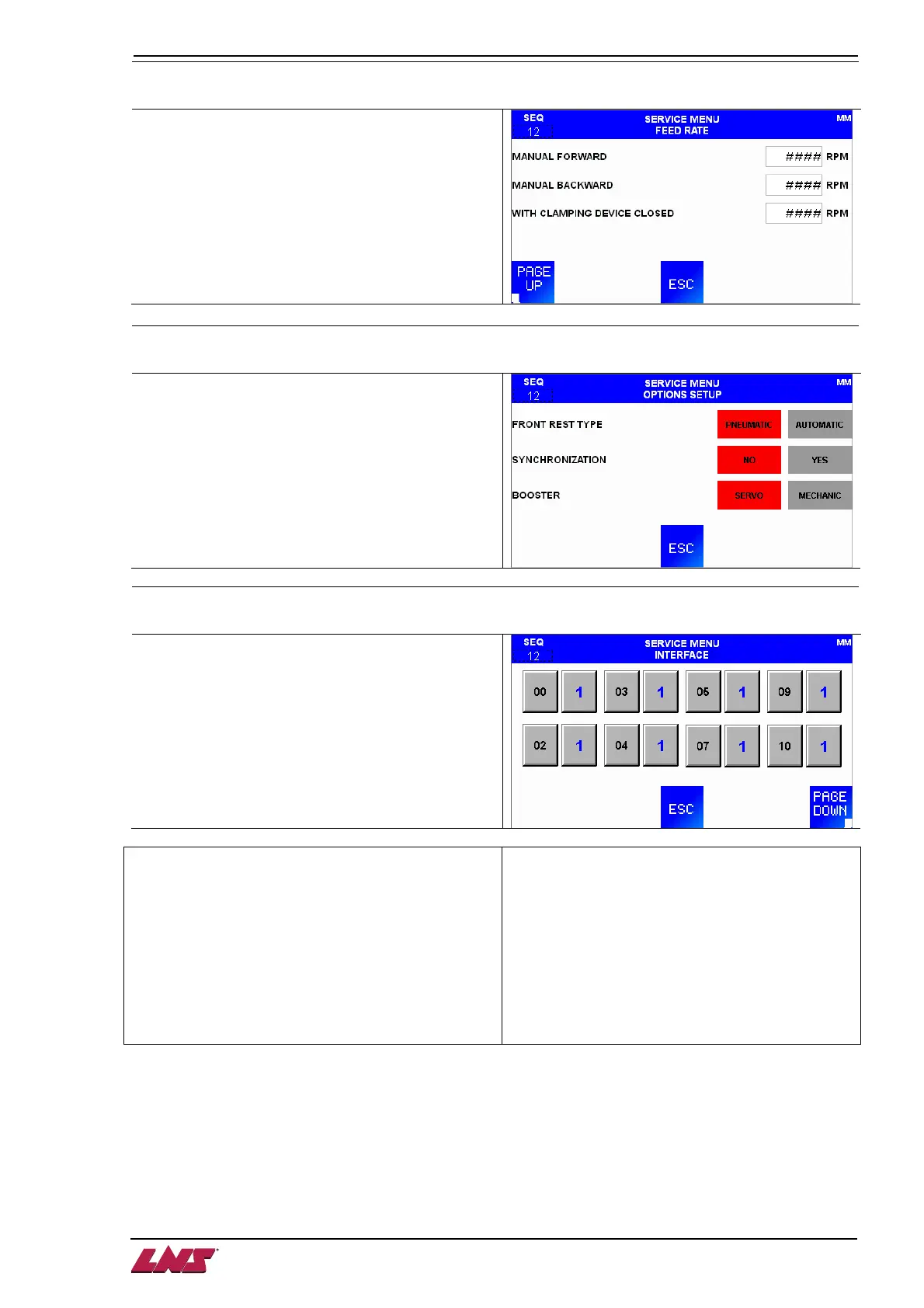

SERVICE: Feed rate 2

Feed rate values.

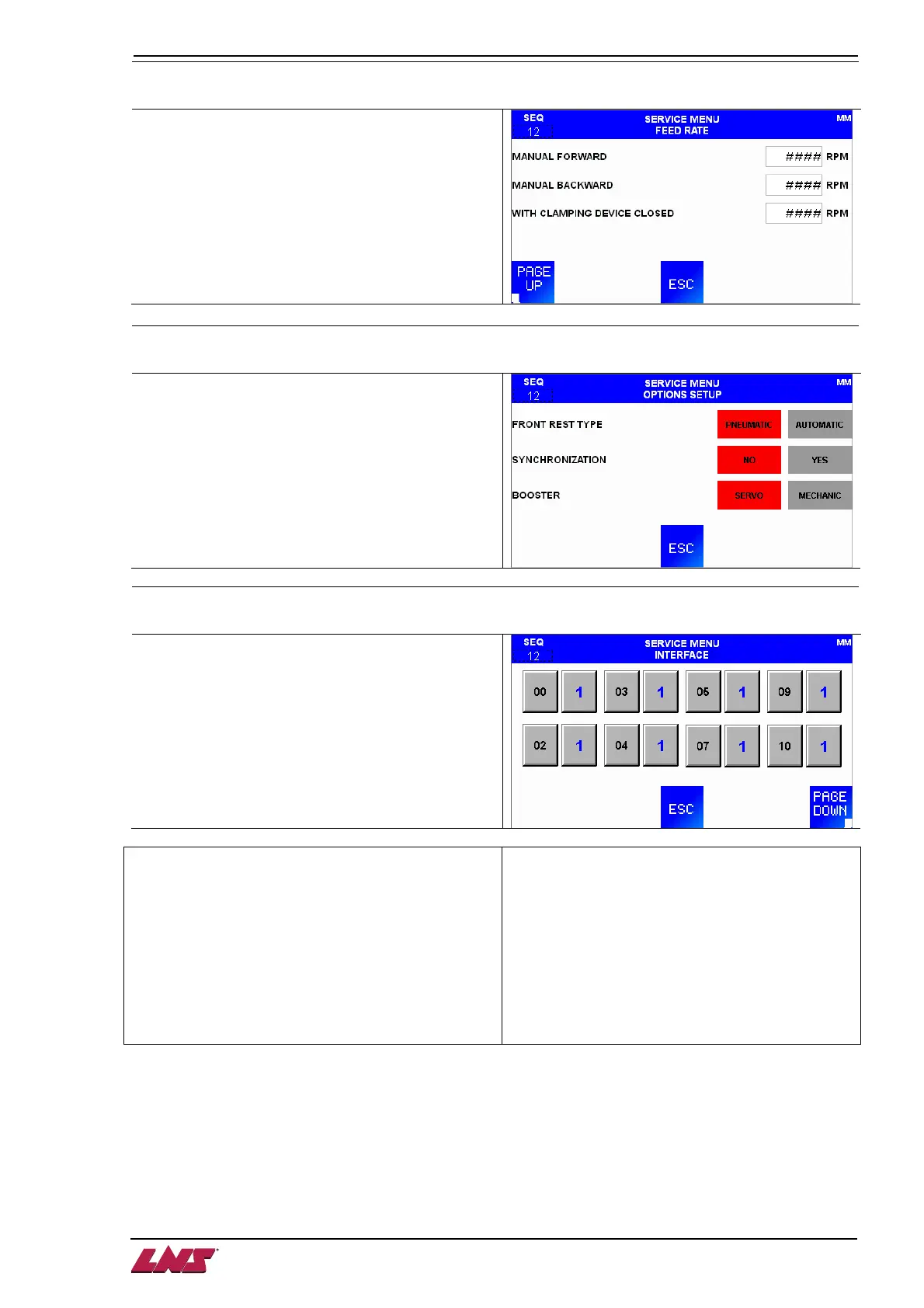

SERVICE: Options setup

Defines the front rest type, if the bar feeder uses a

synchronization system and allows to choose

booster options.

SERVICE: Interface

Shows several interface parameter status.

Please refer to the list below for IP numbers

description.

PI00: A1-clamping signal closed/open

PI01: <not in use>

PI02: Pusher Motion Control Yes/no

PI03: Loading interrupt if A2 or A4 not activated no/yes

PI04: (A3) Priority load command from lathe no/yes

PI05: EOB signal required by the lathe yes / no

PI06: Loading cycle enabled at clamping opening/closing

PI07: Lathe headstock is fixed/sliding

PI08: <not in use>

PI09: Push signal from the lathe (A2) automatic cycle/A4-M-code adv.

PI10: PLC input A2 is latched/pulsed

PI11: A4 signal is latched/pulsed

PI12: 2 pushing forces (sliding headstock) no/yes

PI13: R2 while in production cycle off/on

PI14: R2 during End Of Bar off/on

PI15: R2 ON at top cut position until clamping closes/pulsed for 2 seconds

PI16: R2 to confirm top cut only/top cut+M-code

PI17: R3 signal latches at End Of Bar yes/no

PI18: R3 turns on at EOB and turns off at Loading Start / Clamping Opening

PI19: R3 turns on at EOB and turns off at Loading Start / in top cut position

PI20: R3 pulses for 2 seconds at End Of Bar no/yes

PI21: R5 ON at Auxiliary EOB during Aux. EOB/Until bar loaded

PI22: Clamping device closed to start AUTO yes/no

PI23: <not in use>

PI24: Automatic signal connected to (A2) yes/no

PI25: <not in use>

PI26: <not in use>

PI27: <not in use>

PI28: <not in use>

PI29: <not in use>

PI30: Feed out control alarm yes/no

PI31: EOB calculated acc. to part length yes/no

PI32: R3 turns ON at clamping open/clamping close

PI33: R3 turns ON at EOB and turns off at Loading Start/Until bar loaded

PI34: <not in use>

PI74-75: Time for clamping (sec.) to close / to open

PI43: R5 is aux. EOB / inching

PI44: Lathe’s door open NC/NO

PI45: A2 signal NC/NO

PI46: A4 signal NC/NO

Loading...

Loading...