7-8 CHAPTER 7: OPERATION

QUICK LOAD SERVO III MI

3.2. Lathe mechanical setup

3.2.1. Clamping method

Collets

There are different kinds of collets that are more or less effective:

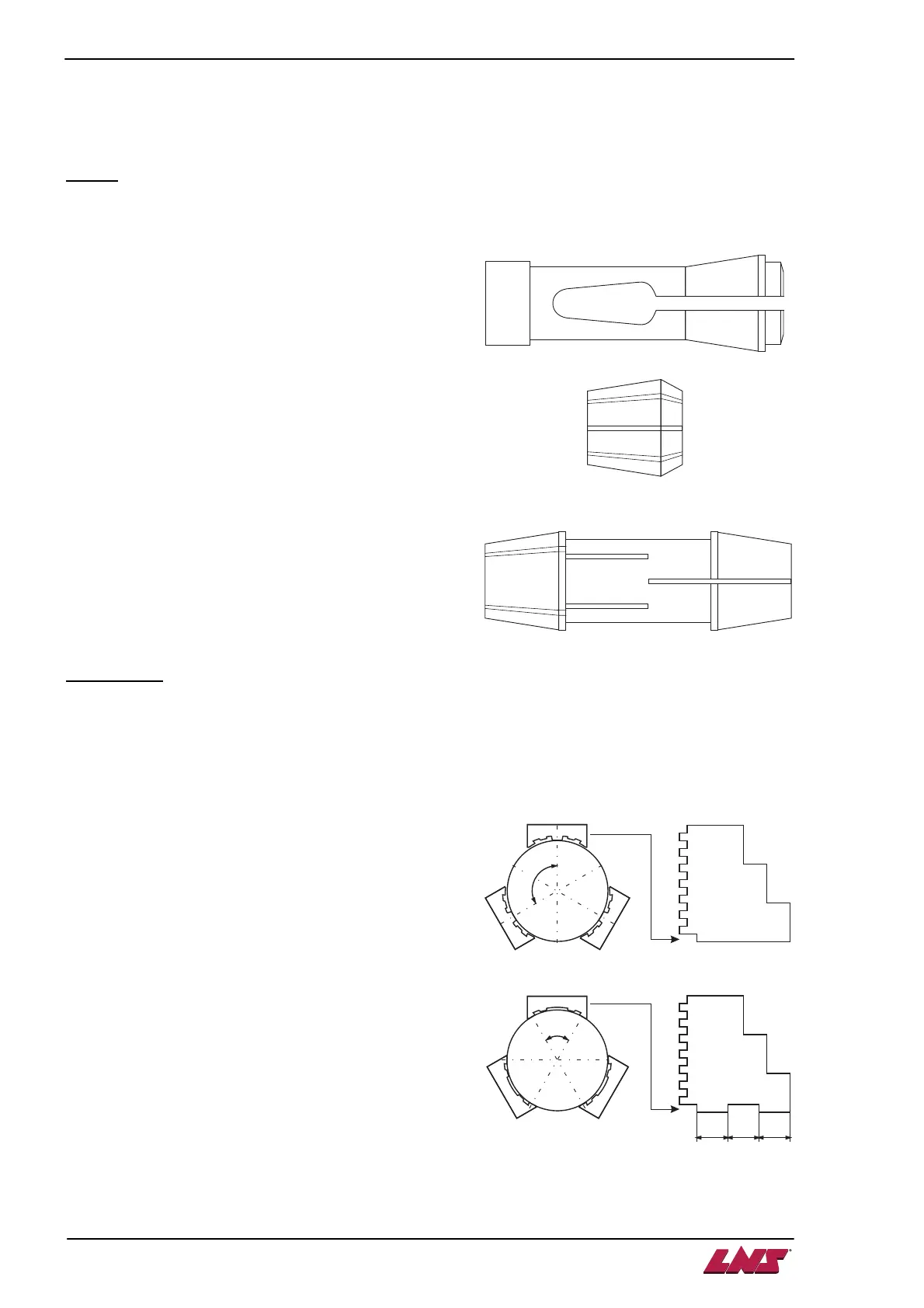

a) Simple cone collet

The bar is held over about 350 degrees, over a

length from 0.5 to 7 times the diameter.

Efficiency : good to very good

b) Bi-conical collet

Clamping over 1 or 2 x 350 degrees, over an

approximate length of 1.2 times the diameter.

Efficiency : very good to excellent

c) Double cone collet

The double cone clamp has the great advantage

of holding the bar at two points separated by

about 1.5 the diameter, with a clamping 2 times

350 degrees over about 0.5 times the diameter.

Efficiency : excellent

3-jaws chuck

With this type of clamping, one should be very careful given that in many cases the bar is held only at

three points, thereby greatly increasing the risk of vibration.

Frequent errors and possibilities for improving the effectiveness of the clamping grip.

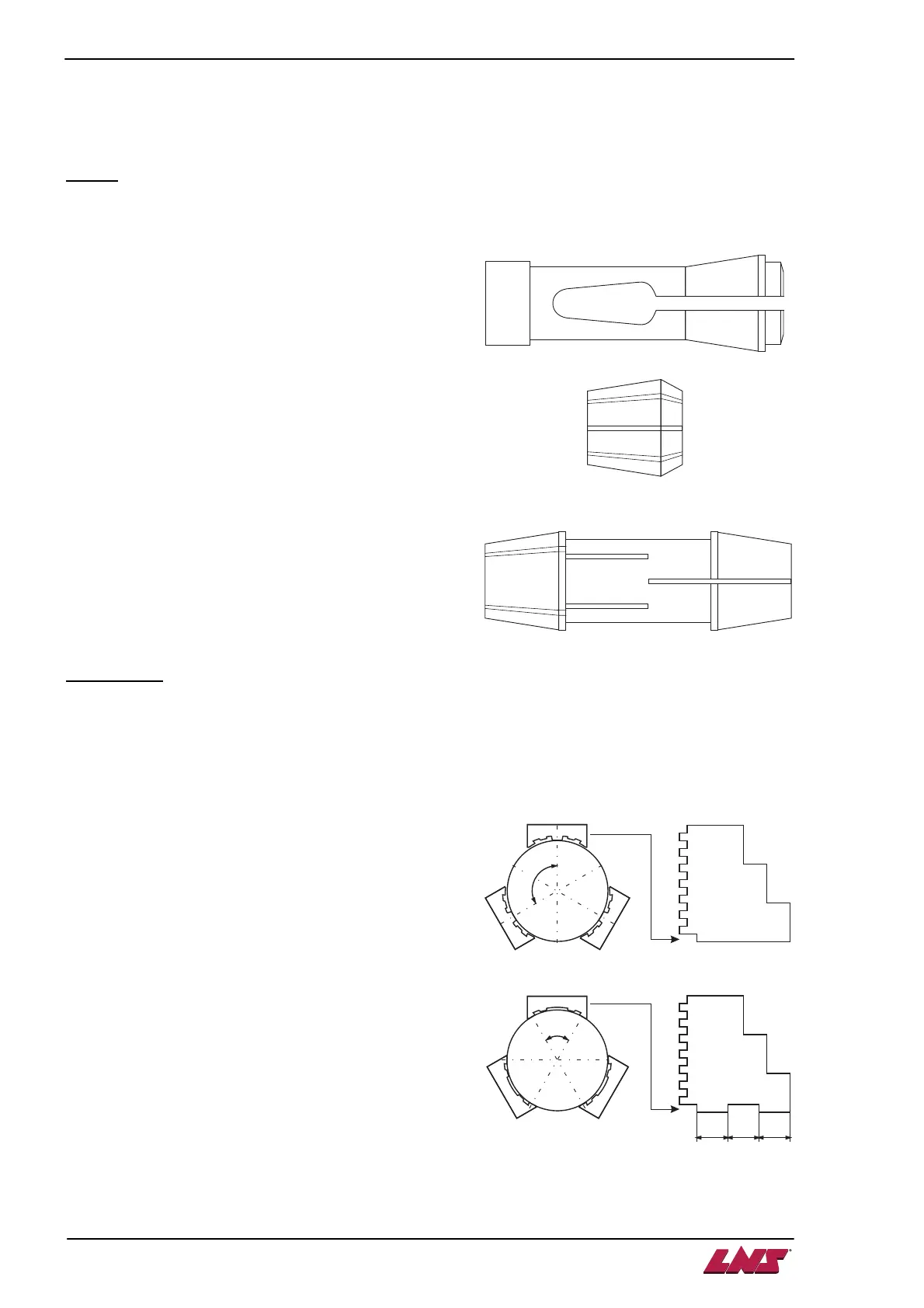

a) Hard grips

Wrong :

The radius of the grip is greater than the radius of

the bar.

The jaws press against only 3 points at 120

degrees.

Correct :

Modify the centres of the jaws to obtain 2 times 6

support clamping points at 60 degrees.

Loading...

Loading...