Operating Instructions

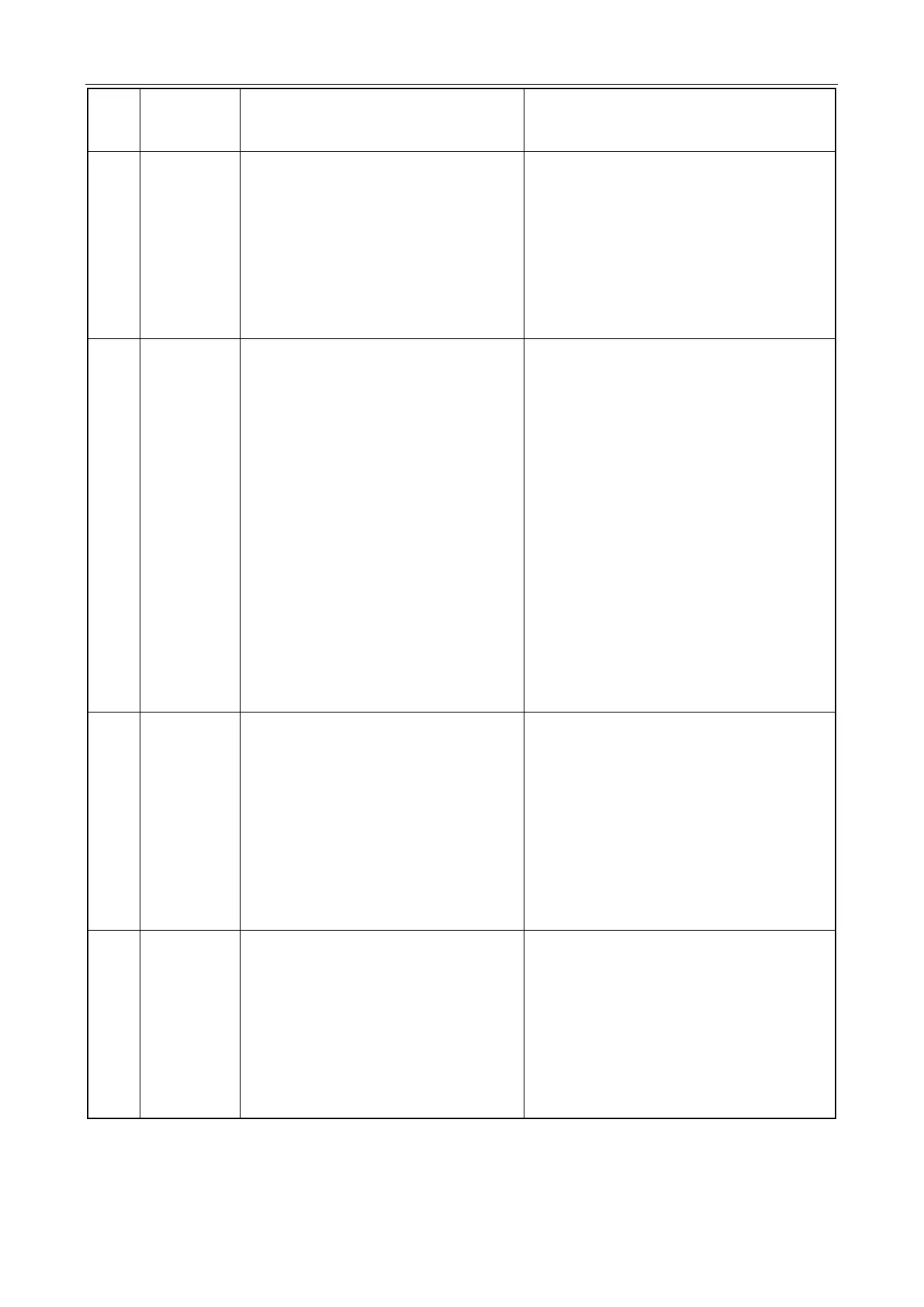

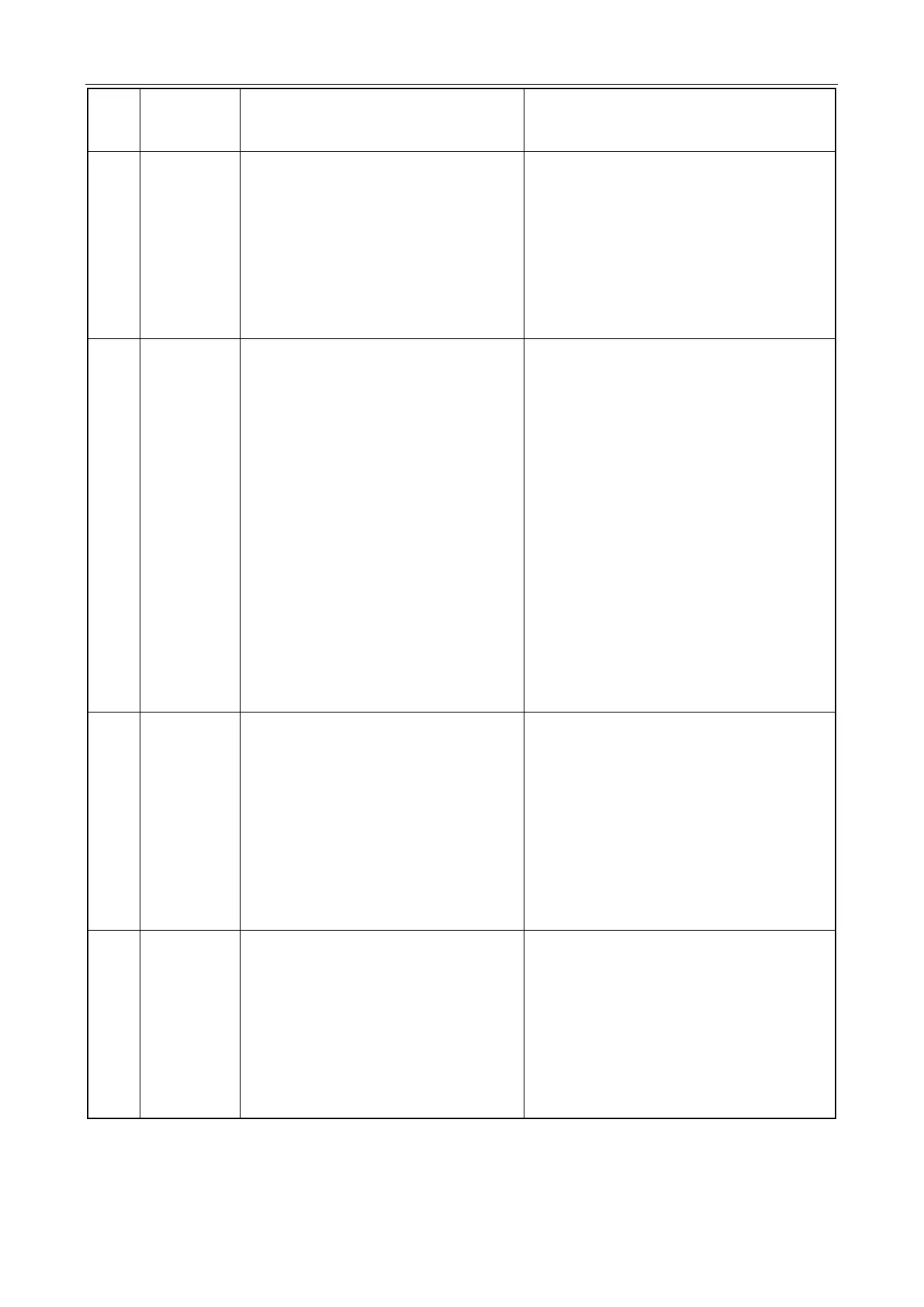

Farm

implement

jittering

during

lifting, and

slow lifting

(1) Oil filter clogging

(2) The air enters the oil suction pipe.

(3) The gear oil pump fails.

(4) Hydraulic oil level excessive low

(1) Clean or replace the filter element

(2) Eliminate the air leakage at the joint and

O-ring.

(3) Replacement of gear oil pump

(4) Add the lubricating oil as required.

Frequent

"nodding"

after farm

implement

lifting, and

fast static

settlement

after engine

shutdown

(1) The distributor one-way valve is not

tightly sealed.

(2) The lowering valve is not tightly

sealed.

(3) The cylinder safety valve leaks or is

improperly adjusted.

(4) The cylinder piston O-ring is

damaged and leaks.

(5) The sealing ring between the

distributor or cylinder head and the oil

inlet hole of lifter housing is poorly

installed, falls off or is damaged.

(1) Clean the one-way valve, and face up it if

necessary.

(2) Clean or face up the lowering valve.

(3) Repair or readjust the cylinder safety

valve.

(4) Replace the O-ring

(5) Replace the sealing ring

Sharp sound

from the

distributor

when the

handle is in

the lifting

position.

(1) The adjustment is incorrect, the inner

lifting arm is used to lift the lifter housing

to open the safety valve.

(1) Firstly, measure the lifting height of farm

implements at this time, and then readjust and

shorten the force and position adjusting rod

so that the highest lifting position is lower

than the original position.

No

hydraulic

output or

weak output

of cylinder

head

(1) The oil inlet line of oil cylinder is not

cut off.

(2) The front cone of lowering speed

control valve and the taper hole are not

tightly sealed.

(1) Tighten the lowering speed control

handwheel clockwise.

(2) Face up and repair the front cone of

lowering speed control valve and taper hole,

or replace the lowering speed control valve.

Loading...

Loading...