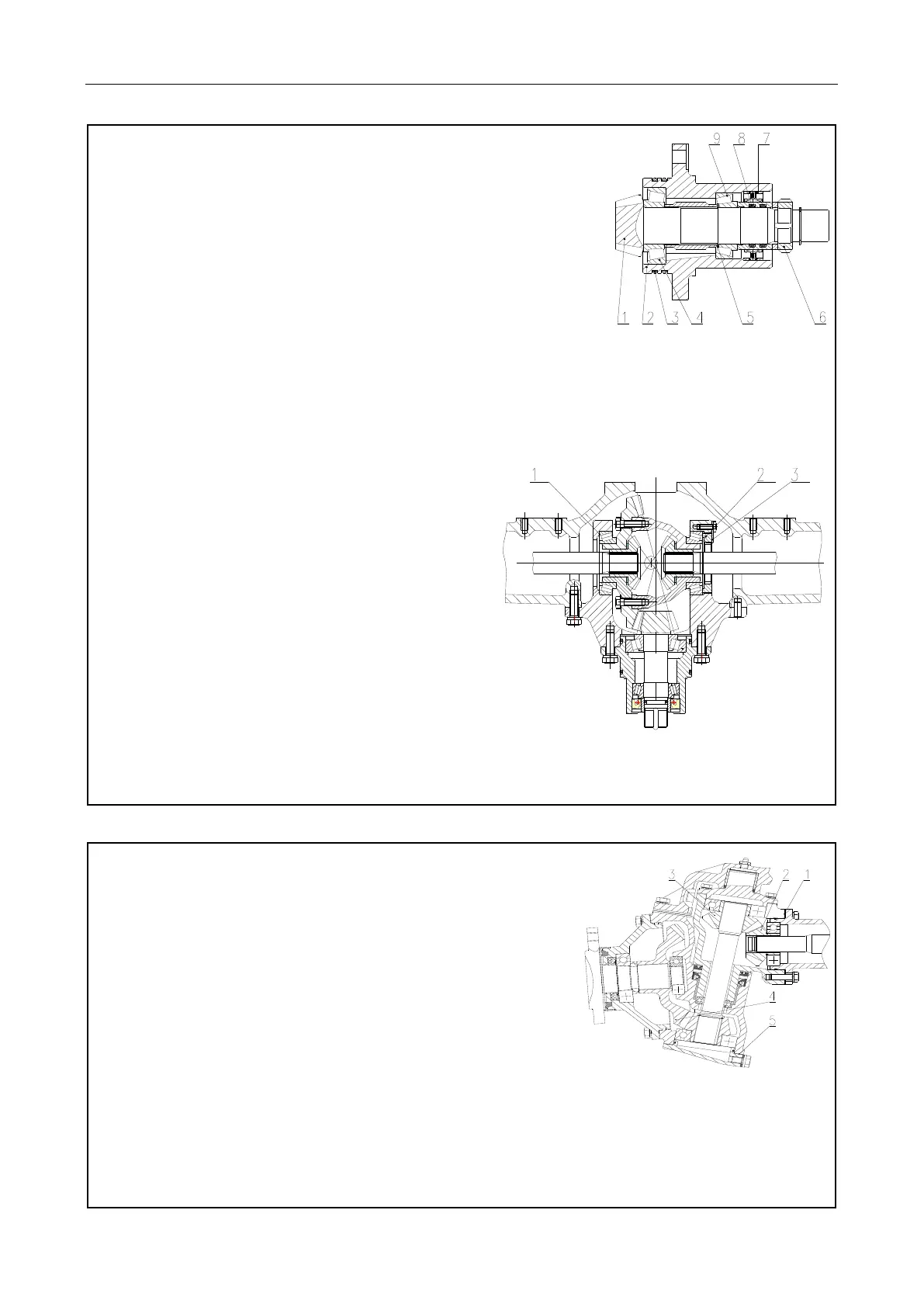

5.7.1 Adjustment of Central Transmission of Front Drive Axle

The two tapered roller bearings on the small bevel gear shaft of the

front drive axle and the left and right tapered roller bearings on the

differential housing are pre-tightened. During use, the small bevel gear

shaft and the differential housing occur axial clearance due to the wear

of the bearings, so they should be checked regularly every 1600h. The

adjustment of small bevel gear shaft bearing depends on adjusting the

thickness of adjusting washer 5 so that the torque for rotating small

bevel gear shaft independently is (1.0 ~ 2.0) N·m. And then tighten nut

6.

To adjust the bearing of differential housing, select

the appropriate adjusting washer 1, tighten the

adjusting bolt 2, lock the lock washer 3, and rotate

the small bevel gear shaft. If the rotating torque is

(0.27 ~ 0.53) N·m more than that when the

differential is not installed, the pre-tightening is

appropriate. At this time, push the bevel gear axially,

and there should be no movement.

The testing method of backlash and gearing marks is

the same as that of the rear axle central transmission.

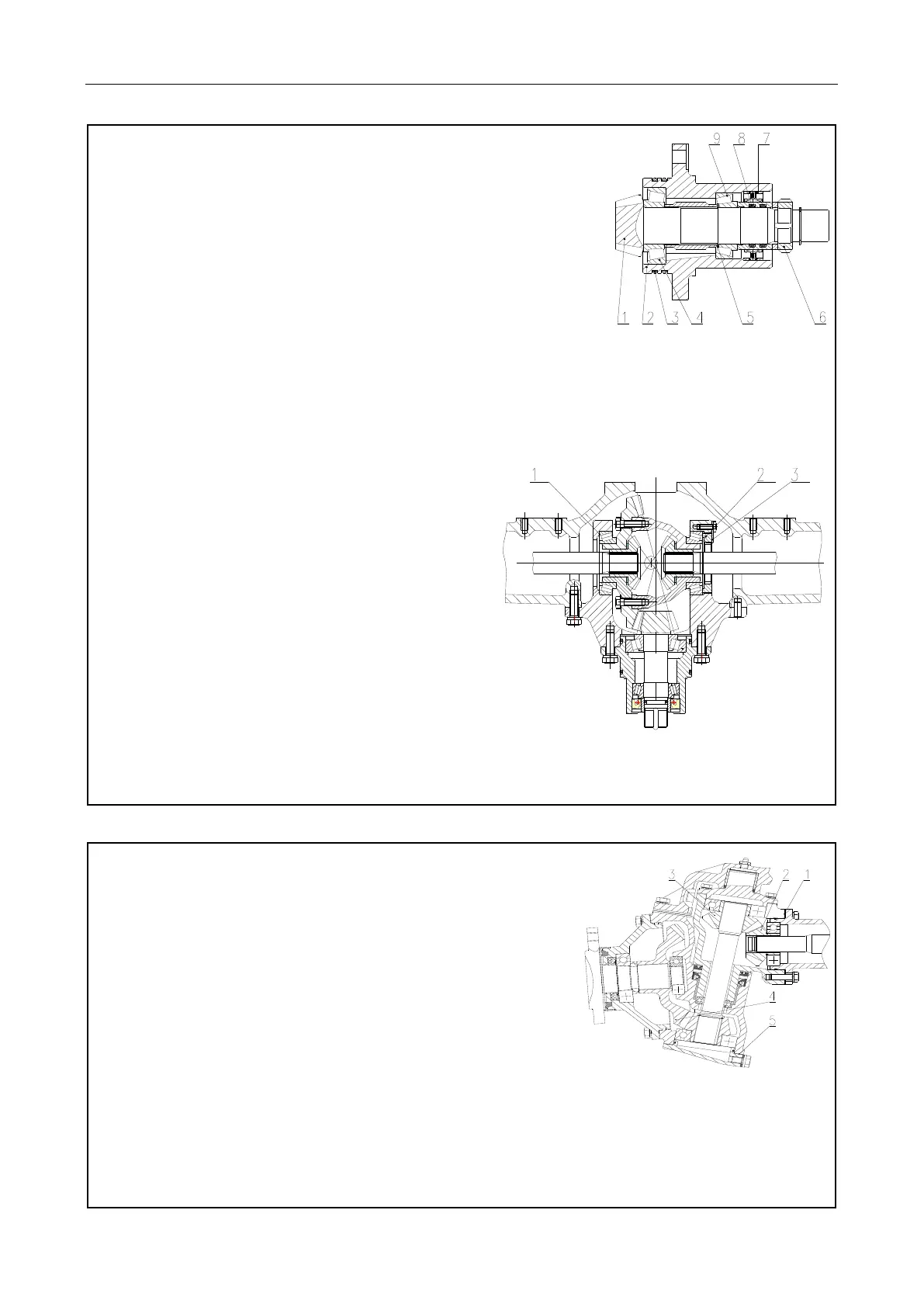

The adjustment of backlash and gearing marks between driving

gear and driven gear of Level I central transmission of front drive axle

side drive depends on adjusting the adjusting washer 1.

And the adjustment of backlash and gearing marks between driving gear

and driven gear of Level II end transmission depends on adjusting the

adjusting washer 5.

The two backlash are both required to be (0.15 ~ 0.25) mm.

Fig. 5-9 Adjustment of Central Transmission of Front Drive Axle

1. Driving bevel gear shaft 2. Bearing seat of driving bevel gear

shaft 3. O-ring 4. Bearing

5. Adjusting washer 6. Nut 7. Oil seal 8. O-ring 9. Bearing

Fig. 5-11 Adjustment of Side Transmission of Front Drive Axle

1. Adjusting washer 2. Central transmission driving gear

3. Central transmission driven gear 4. End deceleration

driven gear 5. Adjusting washer

Loading...

Loading...