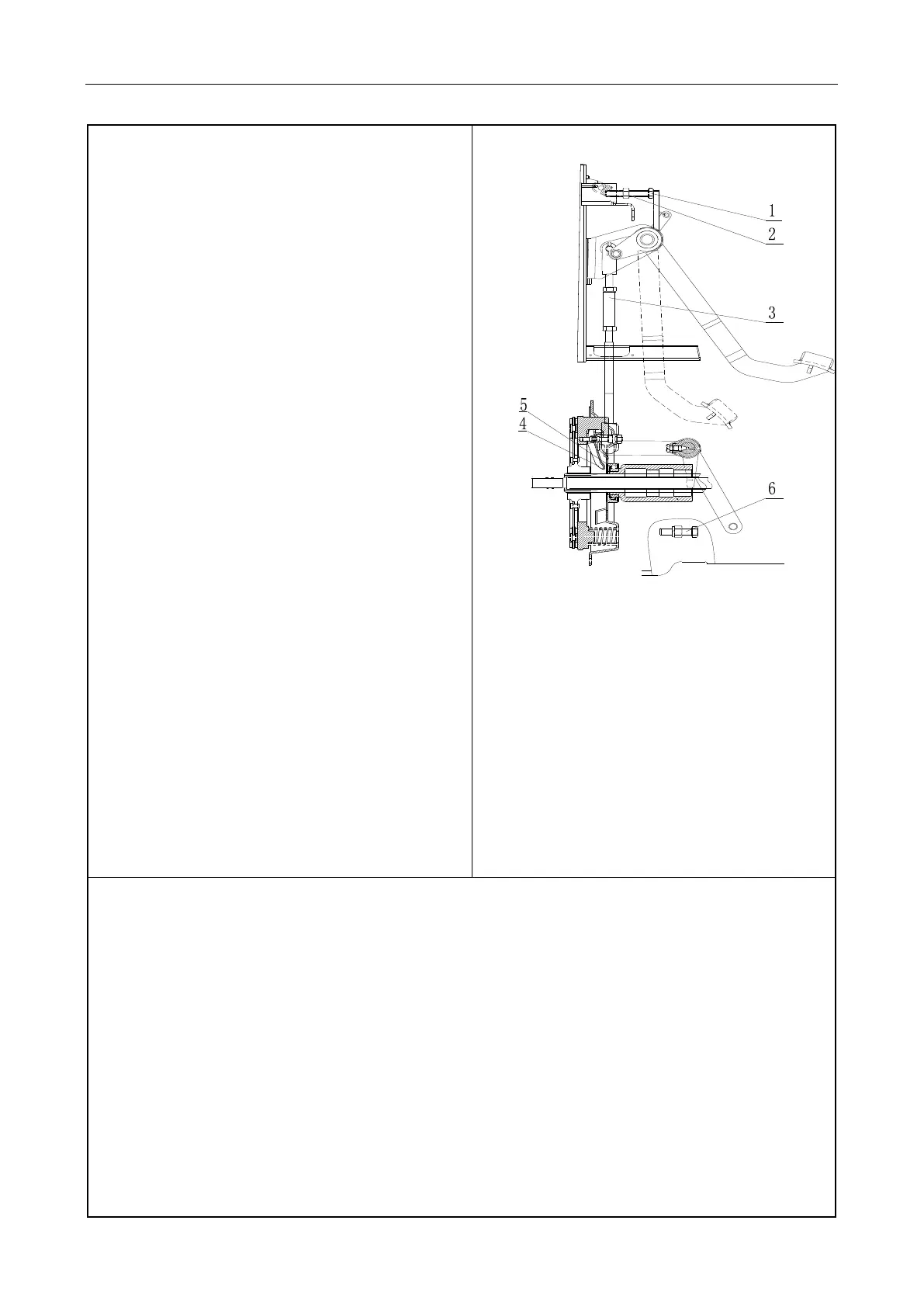

5.2 Adjustment of Clutch

To ensure the normal operation of the clutch, the

clearance between the working face of the main clutch

release lever 4 and the end face of the release bearing 5

must be kept at (2 ~ 2.5) mm. During the clutch is used,

this clearance gradually decreases or even disappears

due to the constant wear of clutch friction plates.

Therefore, the adjustment and inspection must be carried

out regularly.

(1) The clutch control mechanism is adjusted

according to the following steps:

a. Adjust the extension length of the bolt (No.1) to

make the pedal (160~170) mm high, and then lock the

nut (No.2);

b. Adjust the thread connection length at both ends

of the tie rod assembly (No.3) so that the free stroke of

the pedal is (25~32) mm and the free stroke of the release

bearing is (2~2.5) mm, and then lock the tie rod nut;

c. Adjust the screwing depth of the limit bolt (No.6)

to make the total stroke of the clutch pedal (160~170)

mm, and then lock the nut;

d. After the adjustment, the operation of each

operating lever should be flexible without jamming, the

main clutch and the auxiliary clutch should be

completely separated, the gear shift should be flexible,

and the pedal should return freely.

(2) Adjust the height of the clutch release lever (4)

on the special assembly bench so that the three clutch

release levers are in the same plane and in the size of 22,

and the error of the three clutch pressure plate release

levers, in the same plane, is not more than 0.2.

Important matters:

(1) To prevent friction plate from oil stain, frequently unscrew the blowhole plug under the flywheel housing and

discharge the oil stain that may leak into the engine and transmission case. If serious leakage is found, the

cause shall be found out in time and eliminated. Clean the friction plate with gasoline (or kerosene) if

necessary.

(2) To prevent and avoid wear of friction plate, the clutch shall be maintained and adjusted frequently. Do not

casually disengage and engage the clutch in use. When people are disengaging the clutch, the clutch pedal

shall be stepped down to the bottom quickly. Never work in the semi-engaged state, so as not to damage

the clutch.

(3) It is strictly prohibited to work when clutch is not adjusted well, which will accelerate the wear of the clutch

friction plate and even burn it.

(4) When installing the clutch, the release bearing 5 (see Fig. 5-1) and the inner cavity of the release bearing seat

shall be filled with lithium-based lubrication grease. Check the release bearing 5 for oil shortage when people are

disassembling the clutch. In the case of oil shortage, put it into heated molybdenum disulfide lithium-based

Loading...

Loading...