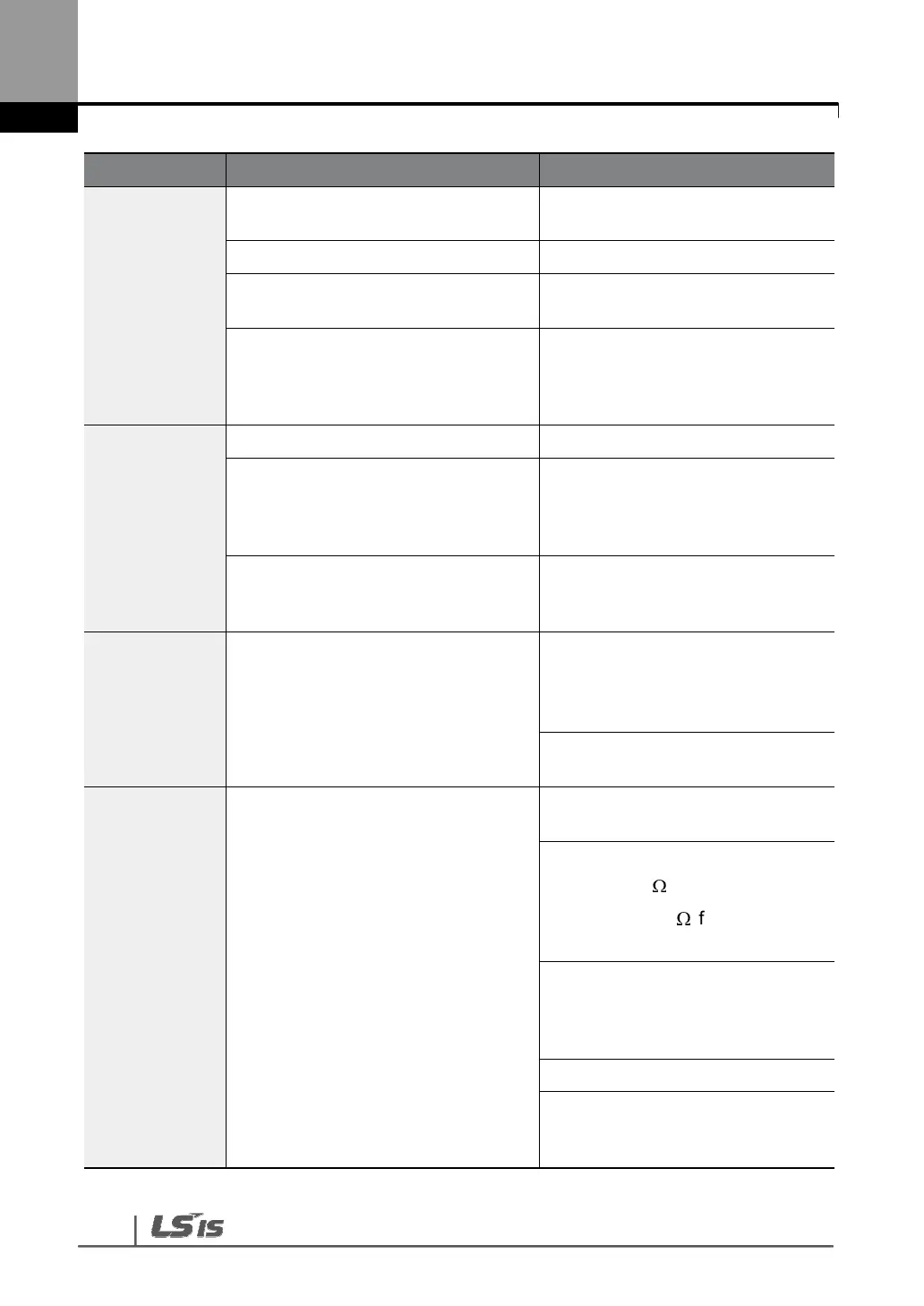

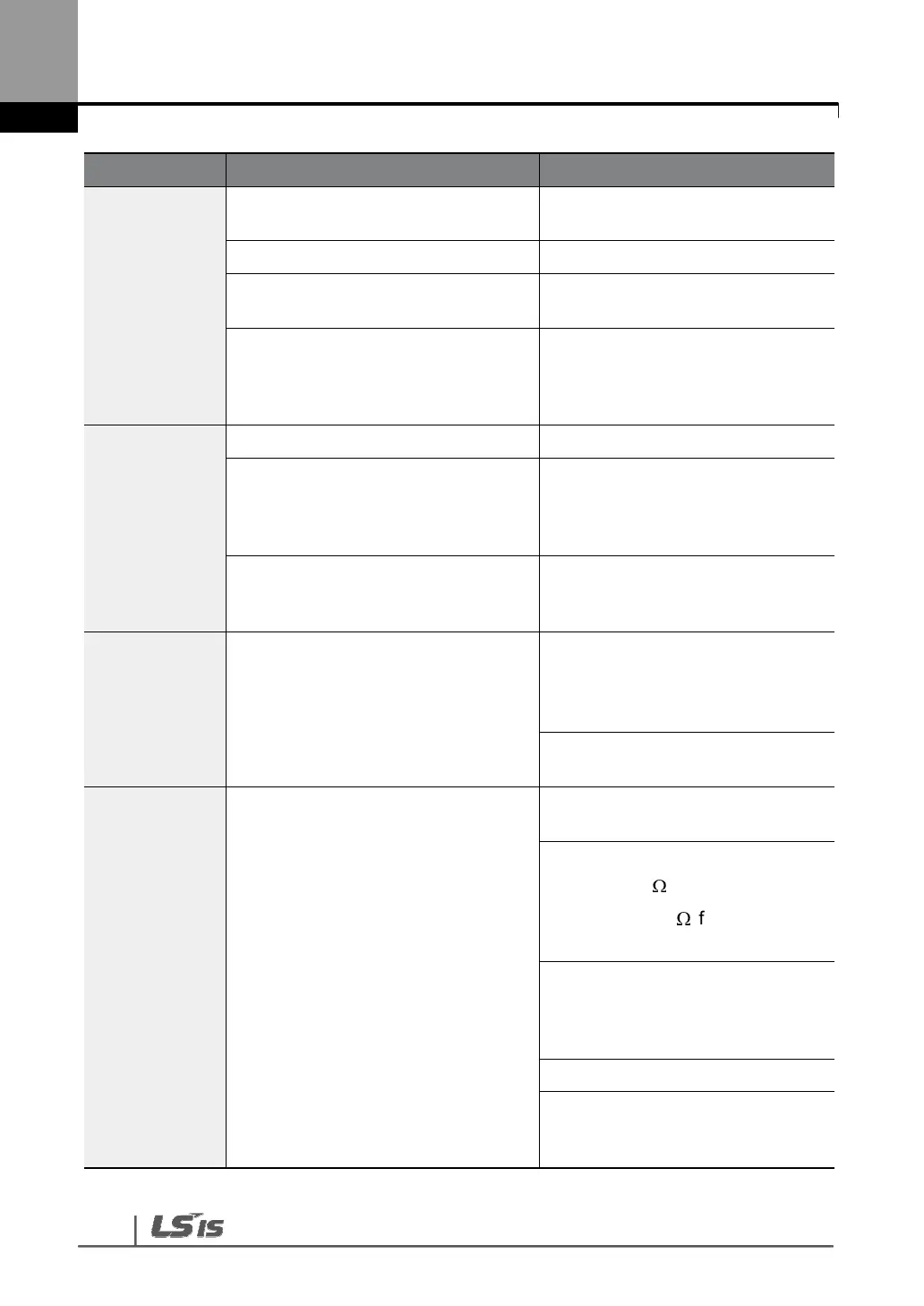

82

Motor speed

varies during

operation.

There is a high variance in load.

Replace the motor and inverter with

models with increased capacity.

The input voltage varies. Reduce input voltage variation.

Motor speed variations occur at a

specific frequency.

Adjust the output frequency to

avoid a resonance area.

The motor

rotation is

different from

the setting.

The V/F pattern is set incorrectly.

Set a V/F pattern that is suitable for

the motor specification.

The motor

deceleration

time is too long

even with

Dynamic

Braking (DB)

resistor

connected.

The deceleration time is set too long. Change the setting accordingly.

The motor torque is insufficient.

If motor parameters are normal, it is

likely to be a motor capacity fault.

Replace the motor with a model

with increased capacity.

The load is higher than the internal

torque limit determined by the rated

current of the inverter.

Replace the inverter with a model

with increased capacity.

While the

inverter is in

operation, a

control unit

malfunctions or

noise occurs.

Noise occurs due to switching inside

the inverter.

Change the carrier frequency to the

minimum value.

Install a micro surge filter in the

inverter output.

When the

inverter is

operating, the

earth leakage

breaker is

activated.

An earth leakage breaker will interrupt

the supply if current flows to ground

during inverter operation.

Connect the inverter to a ground

terminal.

Check that the ground resistance is

less than 100

Ω

for 200 V inverters

and less than 10

Ω

for 400 V

inverters.

Check the capacity of the earth

leakage breaker and make the

appropriate connection, based on

the rated current of the inverter.

Lower the carrier frequency.

Make the cable length between the

inverter and the motor as short as

possible.

Loading...

Loading...