20

A. Identify hardware size and grade.

B. Refer to Torque Chart, page 78 and find correct torque for your hardware size and grade.

C. Torque hardware to this specification unless otherwise specified.

IMPORTANT NOTE: To keep mounting kit hardware from loosening during loader operation, hardware

must be torqued to specifications.

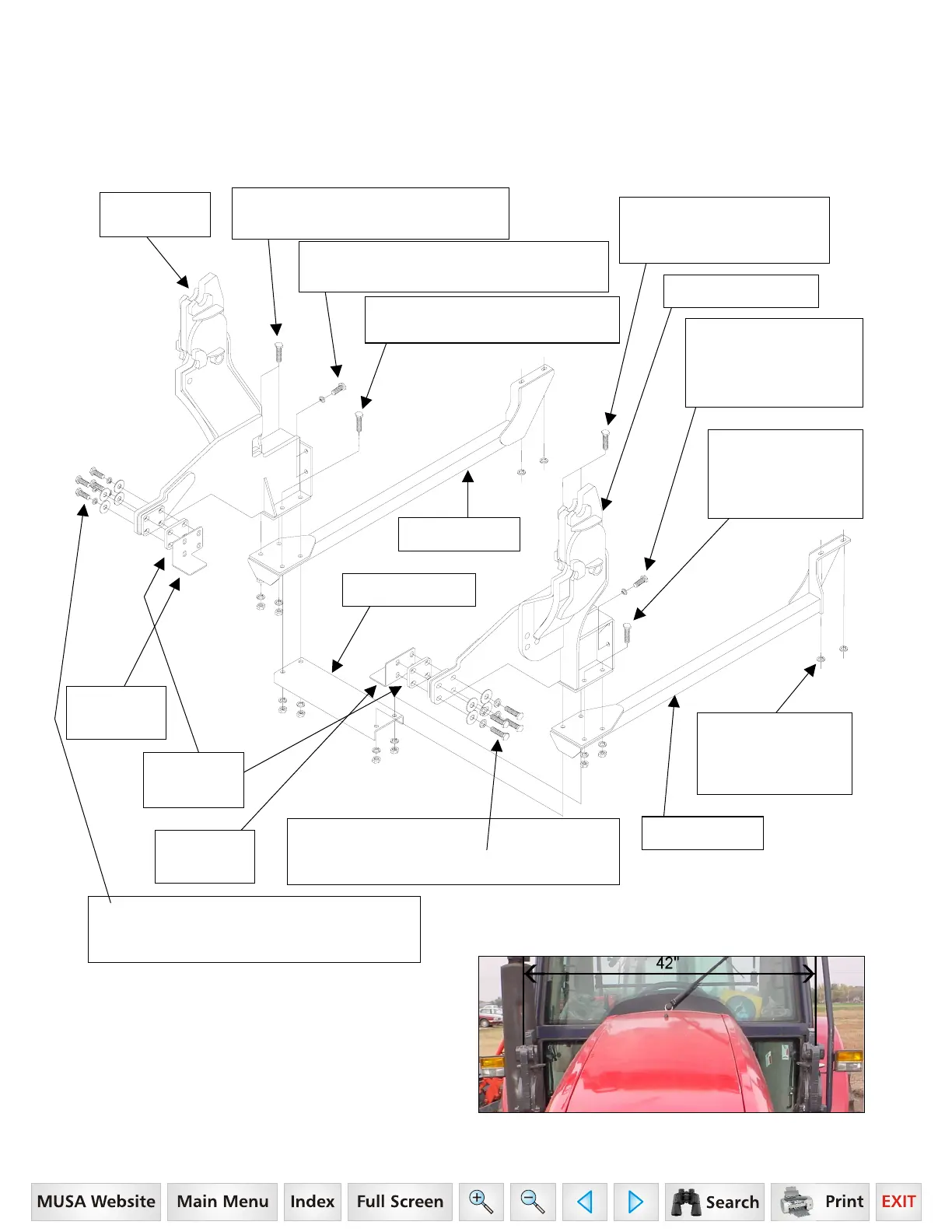

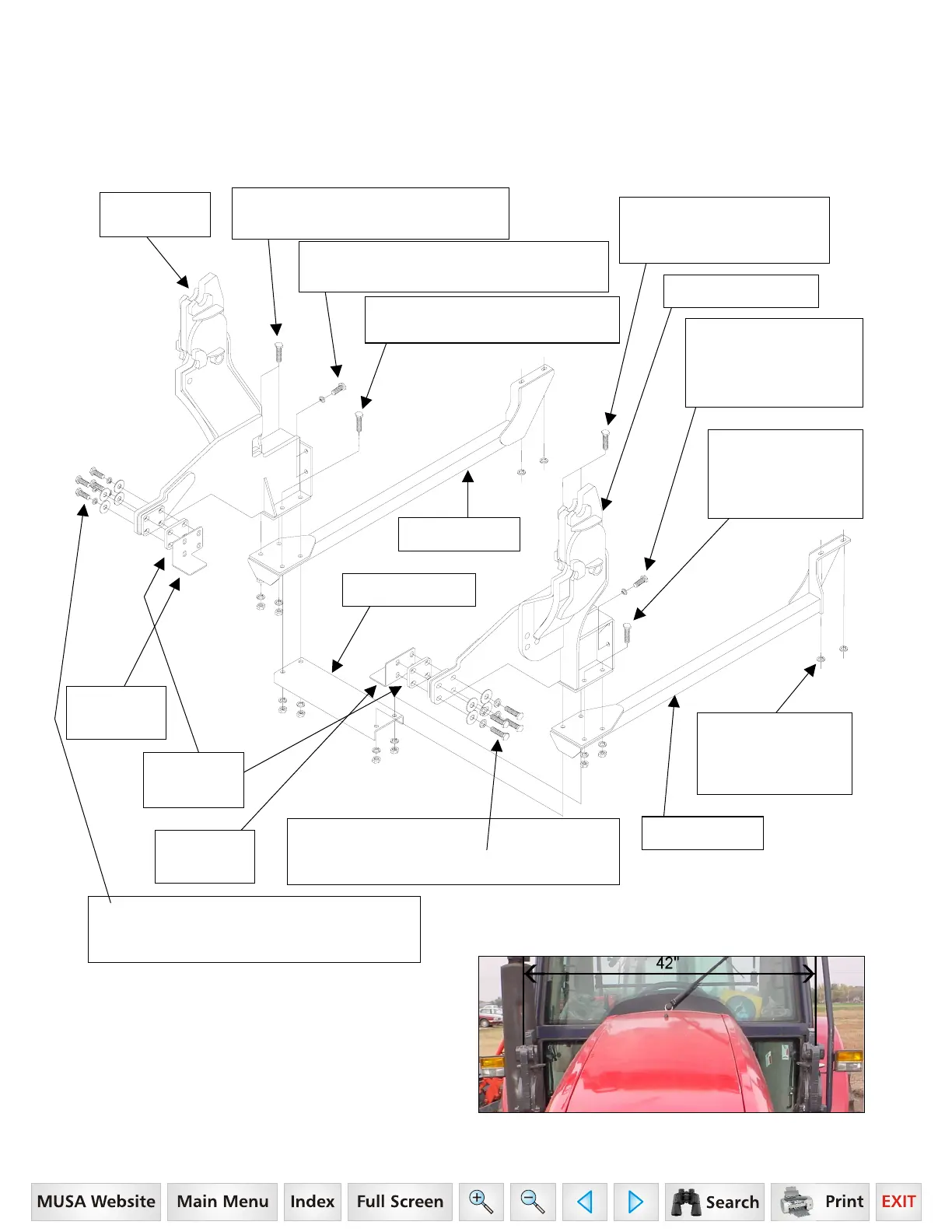

3.2.14. Verify outside surface of brackets are level and

the centerline measurement from RH to LH towers

reads 42" plus or minus 3/8".

1/2" Hardened

Flatwasher plus

Tractor Hardware,

2

laces each side.

16mm x 2.0P x 90mm Hex Bolt Grade 10.9,

5/8" Lockwasher, and 5/8" Hardened

Flatwasher, 4 places each side.

Rear Rail RH

Rear Rail LH

Center

Bracket RH

Center Bracket LH

Oscillation

Stop LH

Crossmember

Oscillation

Stop RH

1/2" 4-Hole

Spacer

5/8" x 1-3/4" Hex

Bolt, Lockwasher,

and Hex Nut

2 places each side.

16mm x 2.0P x 30mm

Hex Bolt Grade 8.8

and 5/8" Lockwasher,

4 places each side.

5/8" x 2" Hex Bolt,

Lockwasher, and Hex Nut,

2 places each side.

16mm x 2.0P x 30mm Hex Bolt Grade 8.8

and 5/8" Lockwasher, 4 places each side.

5/8" x 2" Hex Bolt, Lockwasher,

and Hex Nut

2

laces each side.

5/8" x 1-3/4" Hex Bolt, Lockwasher,

and Hex Nut, 2 places each side.

16mm x 2.0P x 90mm Hex Bolt Grade 10.9,

5/8" Lockwasher, and 5/8" Hardened

Flatwasher, 4 places each side.

Loading...

Loading...