P 32/ 45

Repair

[4] ADJUSTMENT

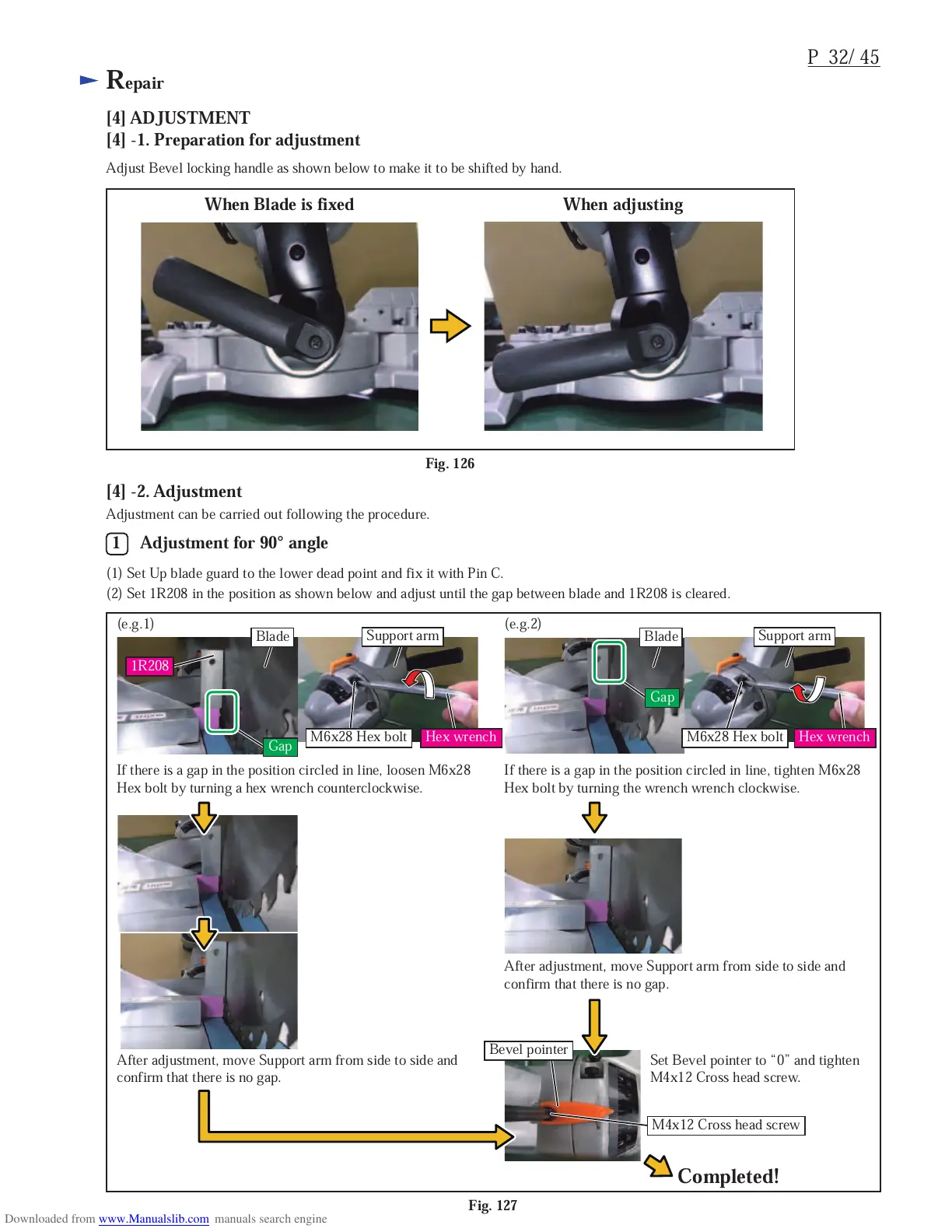

[4] -1. Preparation for adjustment

When Blade is fixed When adjusting

Adjust Bevel locking handle as shown below to make it to be shifted by hand.

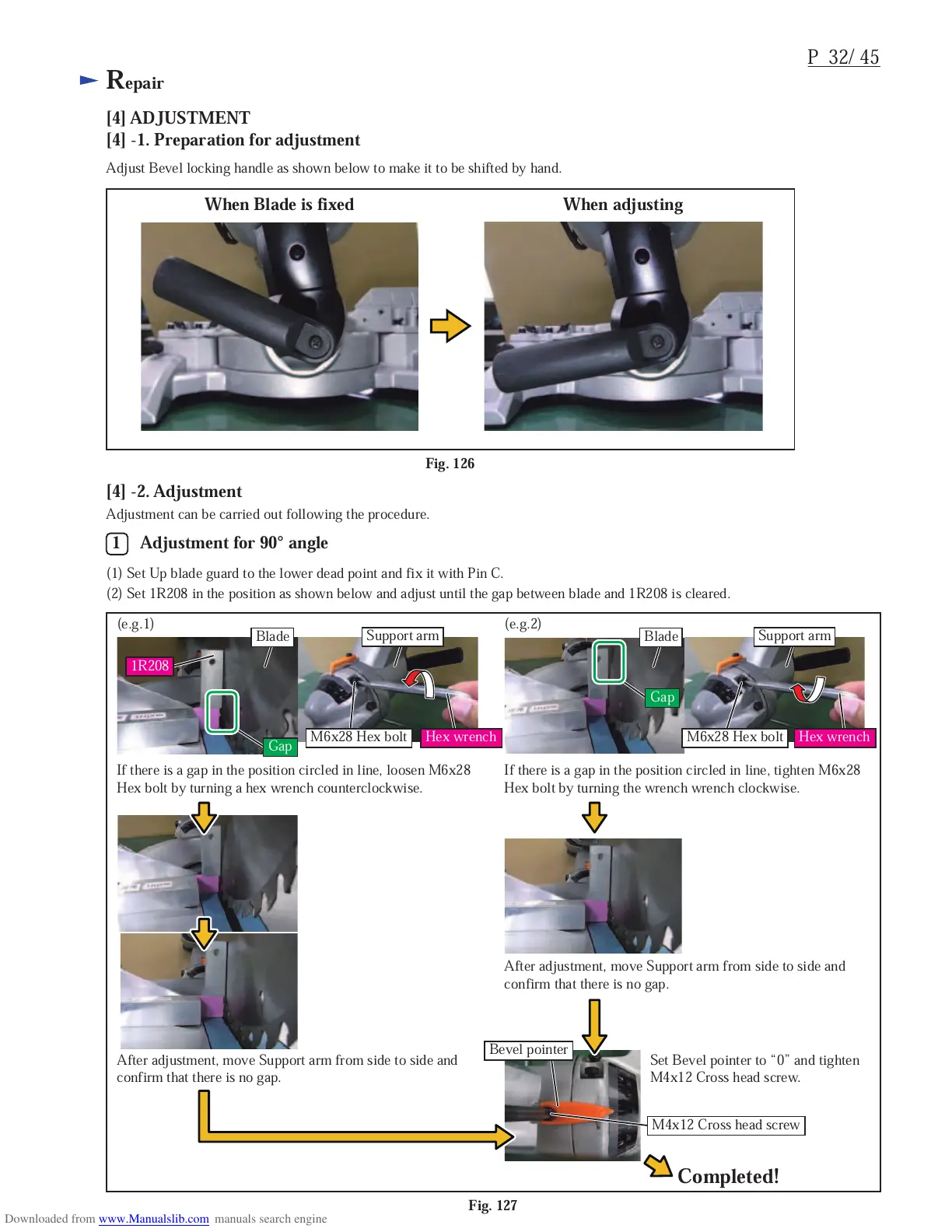

[4] -2. Adjustment

(1) Set Up blade guard to the lower dead point and fix it with Pin C.

(2) Set 1R208 in the position as shown below and adjust until the gap between blade and 1R208 is cleared.

(e.g.1) (e.g.2)

If there is a gap in the position circled in line, loosen M6x28

Hex bolt by turning a hex wrench counterclockwise.

After adjustment, move Support arm from side to side and

confirm that there is no gap.

After adjustment, move Support arm from side to side and

confirm that there is no gap.

Set Bevel pointer to “0” and tighten

M4x12 Cross head screw.

If there is a gap in the position circled in line, tighten M6x28

Hex bolt by turning the wrench wrench clockwise.

Adjustment can be carried out following the procedure.

Fig. 126

Fig. 127

Adjustment for 90° angle

1

Blade Blade

Support arm

Bevel pointer

Support arm

1R208

M6x28 Hex bolt M6x28 Hex bolt

Completed!

M4x12 Cross head screw

Hex wrench Hex wrench

Gap

Gap

Loading...

Loading...