ENGINELUBRICATION

Checkingtheoilpump

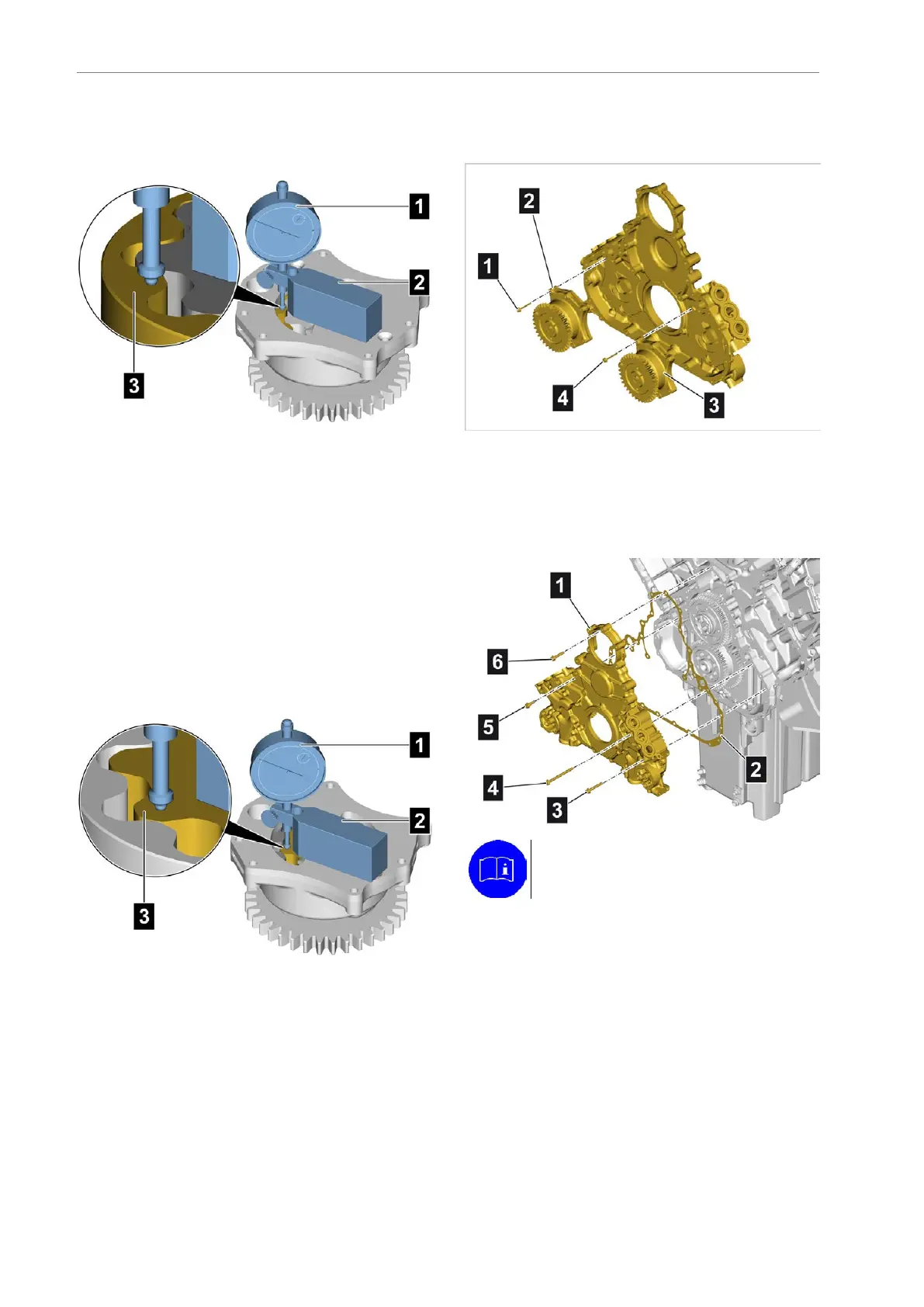

Checkingtheringgearaxialplay

•PlacetheDialgaugeholder[107](2)withDial

gauge[108](1)ontheoilpump

•PlacetheDialgauge[108](1)againsttheringgear

(3)withapreload

•Presstheringgear(3)towardsthedrivegear

•ZerotheDialgauge[108](1)

•Presstheringgear(3)towardstheDial

gauge[108](1)andcheckthedifference

Thepermittedaxialplayontheringgear(3)is0.040

–0.090mm.

Iftheaxialplayisoutoftolerance,tanewoilpump.

Checkingtherotoraxialplay

•PlacetheDialgaugeholder[107](2)withDial

gauge[108](1)ontheoilpump

•PlacetheDialgauge[108](1)againsttherotor(3)

withapreload

•Presstherotor(3)towardsthedrivegear

•ZerotheDialgauge[108](1)

•Presstherotor(3)towardstheDialgauge[108]

(1)andcheckthedifference

Thepermittedaxialplayontherotor(3)is0.035–

0.080mm.

Iftheaxialplayisoutoftolerance,tanewoilpump.

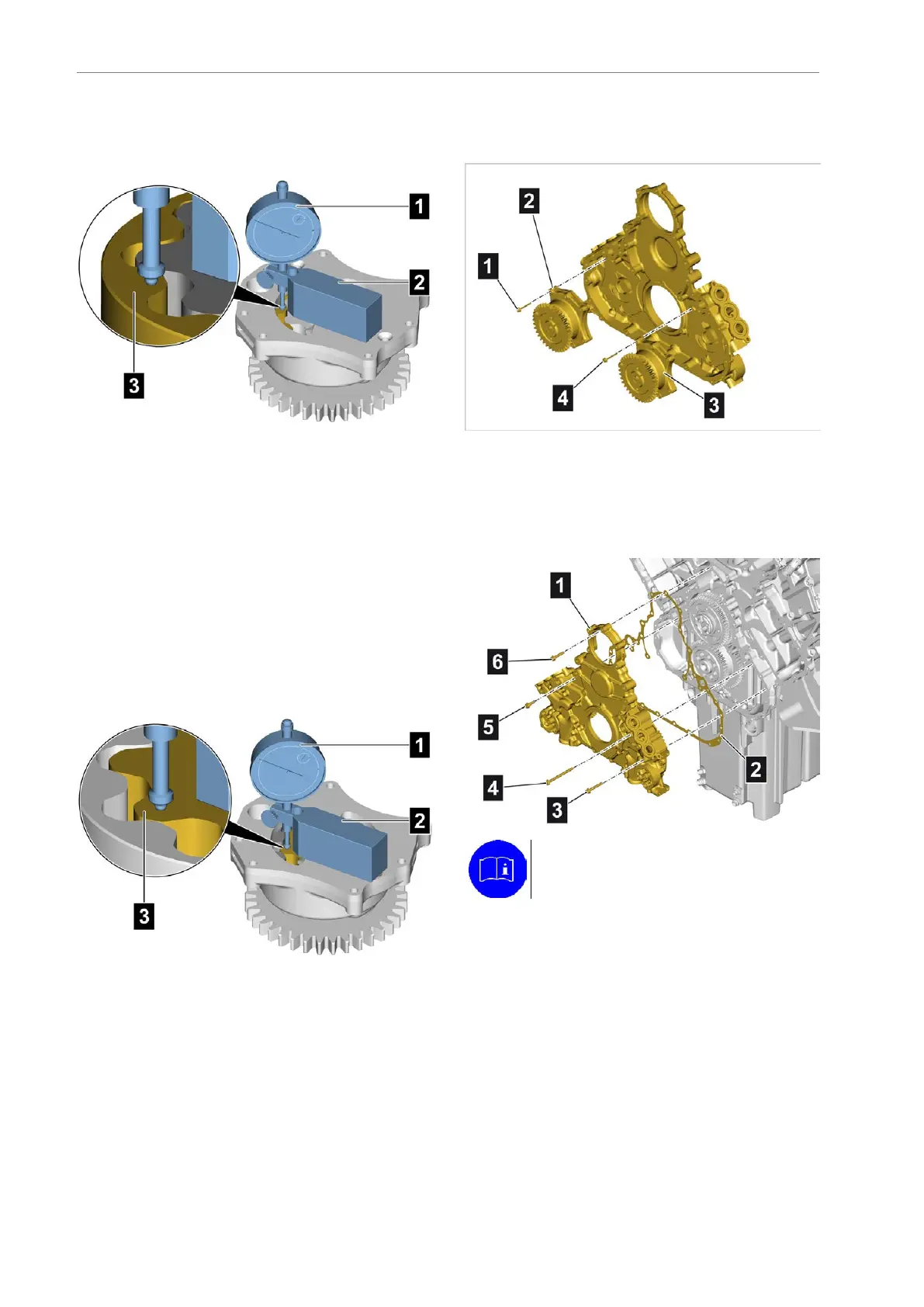

Installingoilpumps

Installingoilpumps

•Positiontheoilpumps(2)and(3)

•Screwinthenewmountingbolts(1)and(4)and

tightenthembyhandasmarked

•Tightenthemountingbolts(1)and(4)to15Nm

Attachingthecover

Note

Attachthesealwiththescreen-printed

sidefacingthecrankcase.

•Cleanthesealingsurfaces

•Positionthecover(1)withanewseal(2)

•Screwinthenewmountingbolts(3),(4),(5)and

(6)asmarkedandthentightenthem

292AE63stedition

Loading...

Loading...