CRANKCASE

Checkingthecylinderliner

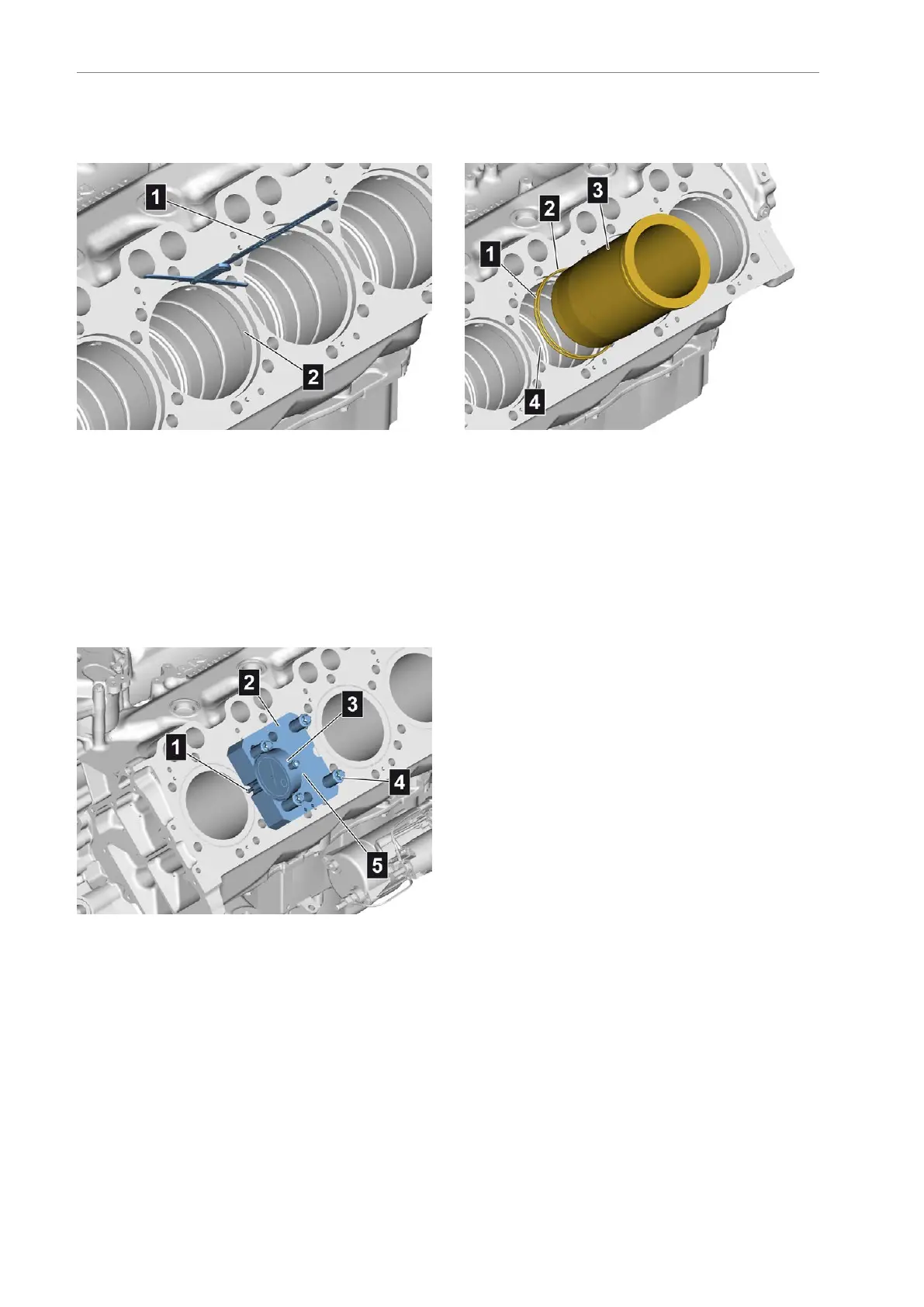

Checkingthecylinderlinerseating

•Checktheseat(2)ofthecylinderlinerwithDepth

gauge(electronic)[175](1)

•Checkthecylinderlinerseat(2)atfour

opposite-facingpoints

Thepermittedcollarrecessdepthis9.850–10.150

mm

Ifthecollarrecessdepthisoutoftolerance,tanew

crankcaseandcylinderliners.

Measuringthecylinderlinerstandout

•PuttheMeasuringplate[172](2)onthecylinder

liner

•ScrewintheBolt[173](4)withtheWasher[174]

andtightento40Nm

•PlacetheDialgaugeholder[170](5)withDial

gauge[171](3)onMeasuringplate[172](2)

•Placethedialgaugetip(1)onthecrankcase

•ZerotheDialgauge[171](3)

•Carefullyplacethedialgaugetip(1)onthe

cylinderlinerandnotethedifferenceonthedial

gauge

Thepermissiblecylinderlinerstandoutis0.035–

0.085mm.

Ifthecylinderlinerstandoutisoutoftolerance,ta

newcylinderliner/crankcase.

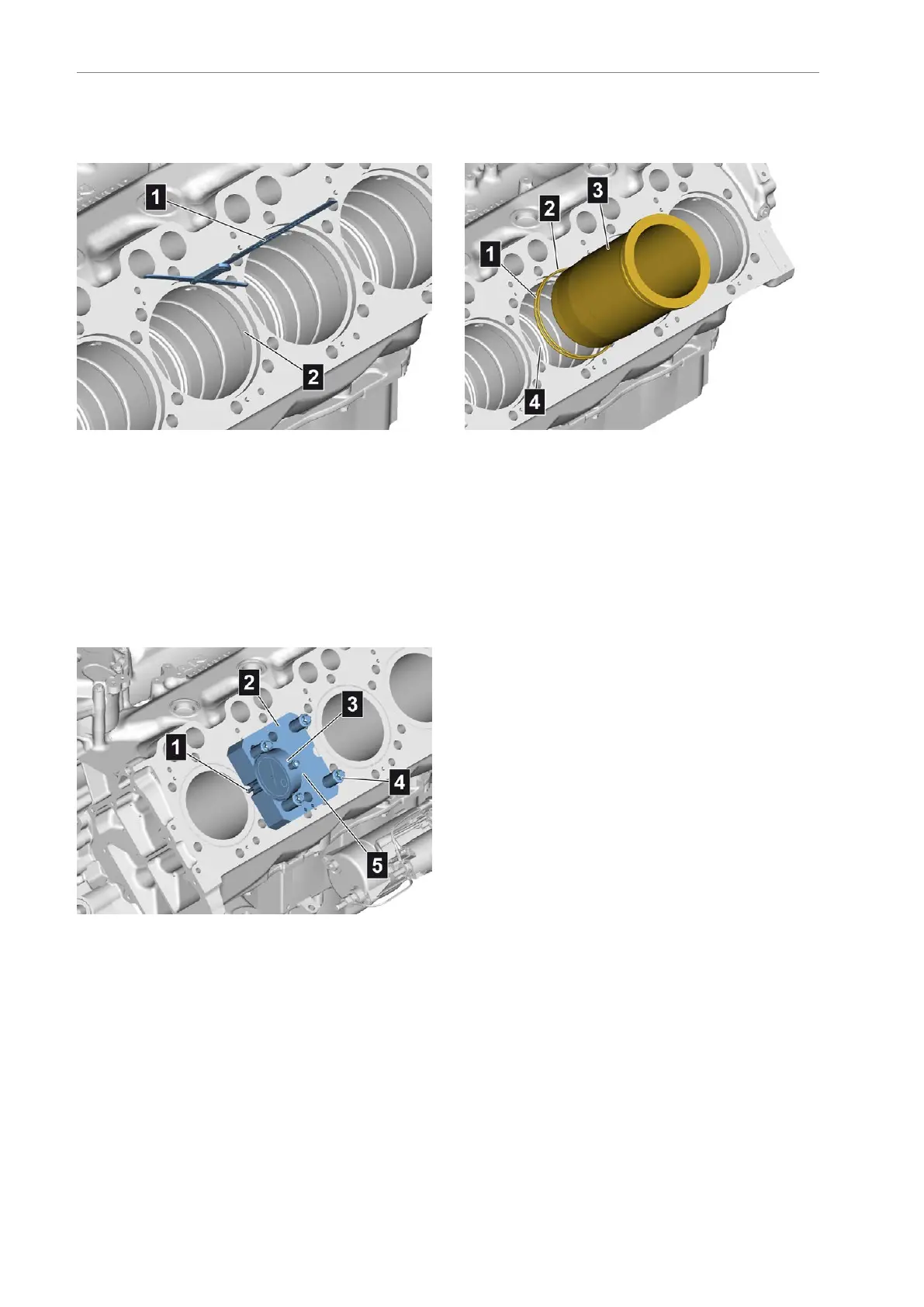

Installingthecylinderliner

Installingthecylinderliner

•LightlyapplycleanengineoiltoMANStandard

3277onthenewsectionalsealingrings(1)and

(2)andtheninsertthemintothesectionalsealing

ringseats(4)

•Insertthecylinderliner(3)intothecrankcaseas

markedandpushitinasfarasthestop

372AE63stedition

Loading...

Loading...