46 M&R Companies 440 Medinah Rd. Roselle, IL 60172 USA

Tel: +630-858-6101 Fax: +630-858-6134 www.mrprint.com | store.mrprint.com

Daily

WARNING: To prevent possible injury to personnel and/or damage to the equipment, lock

out and tag the electrical service to the equipment.

Printing Nozzle Checks

Nozzle Checks should be performed on a daily basis, usually each morning or the beginning of each shift to

confirm the status of the printhead. Nozzle Checks can also be printed anytime there is an abnormality in a

printed image. It is a quick way to confirm whether the printheads are firing at 100%. On the right hand side of the

Main PCS window is the maintenance header bar which is used for Nozzle Checks.

1. Start by loading a screen into the machine. Then lightly spray tack a piece of paper and adhere it to the

upper right hand corner of the screen. The right edge and leading edge should be in alignment with the

pusher frame below.

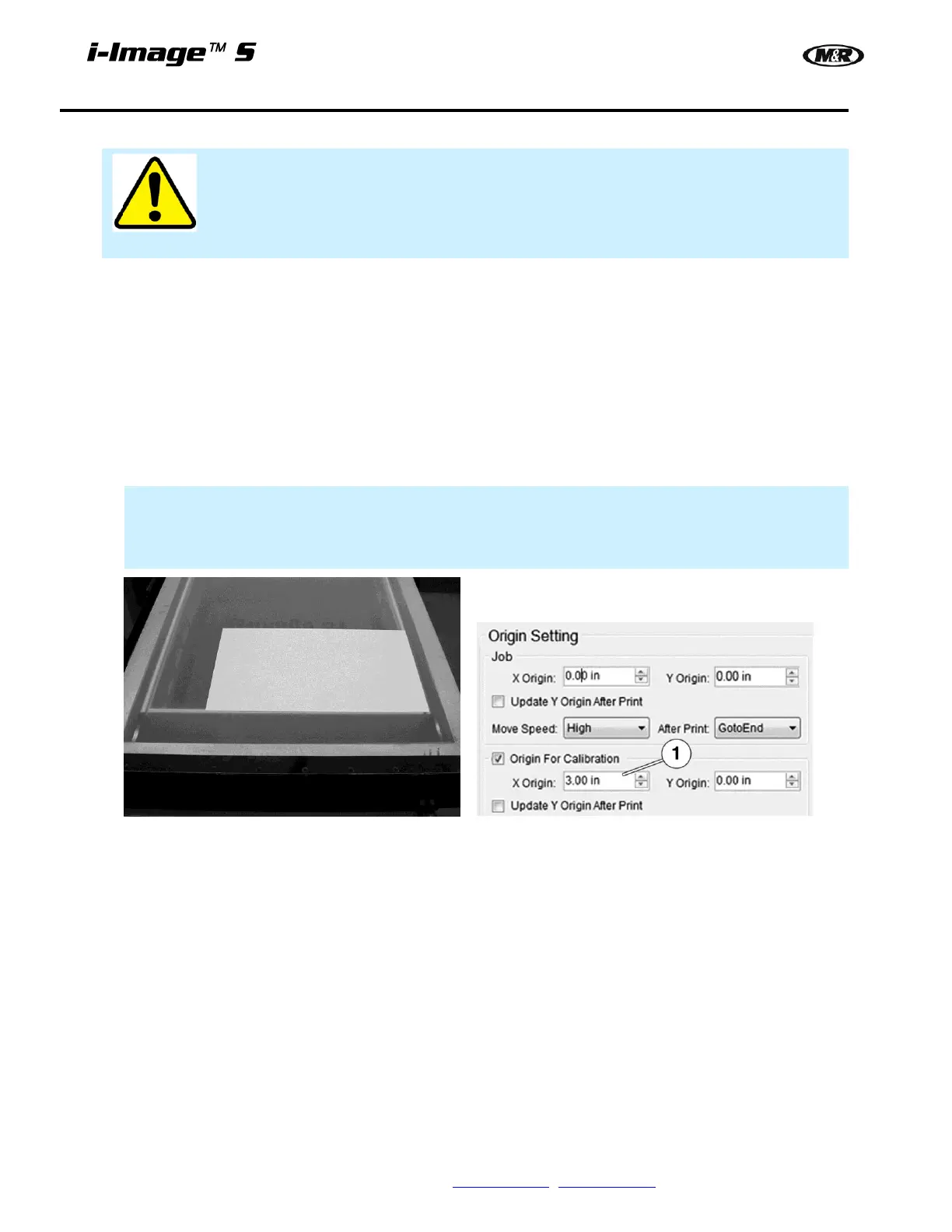

2. In the PCS main window confirm the Origin for Calibration box is selected and the X Origin is set at

3.00 in (1).

Note: Setting the X Origin at 3" inches places the Nozzle Check start position so that it prints on the

upper right hand corner of the paper. For each subsequent nozzle check, increase the X Origin 1.5".

For example, increasing the X Origin to 3" / 4.5’ / 6" / 7.5" / 9" / 10.5" / 12" etc., moves each new

nozzle check across the page to the left.

Loading...

Loading...