INTRODUCTION RT880E SERVICE MANUAL

1-10 Published 11-10-2014, Control # 524-00

Flat metal locks must be installed properly to be effective.

Bend one end of the lock around the edge of the part. Bend

the other end against one flat surface of the nut or bolt head.

Always use new locking devices on components which have

moving parts.

When installing lock washers on housings made of aluminum

or thin sheet metal, use a flat washer between the lock

washer and the housing.

Wires and Cables

Batteries should always be disconnected prior to working on

the electrical system.

When removing or disconnecting a group of wires or cables,

tag each one to ensure proper identification during assembly.

Shims

When shims are removed, tie them together and identify

them as to location. Keep shims clean and flat until they are

reinstalled.

Hoses and Tubes

Inspection

Check hoses carefully. Do not use your bare hands to check

for leaks.

Tighten all connections to recommended torque.

If the hose end connections are damaged, always replace

the hose or tube. Damaged, dented, crushed, or leaking

hose fittings restrict oil flow and the operation of the parts

being served. Fittings showing signs of movement from their

original position have failed and must be replaced.

Be sure hoses are in good condition. If in doubt, replace

them.

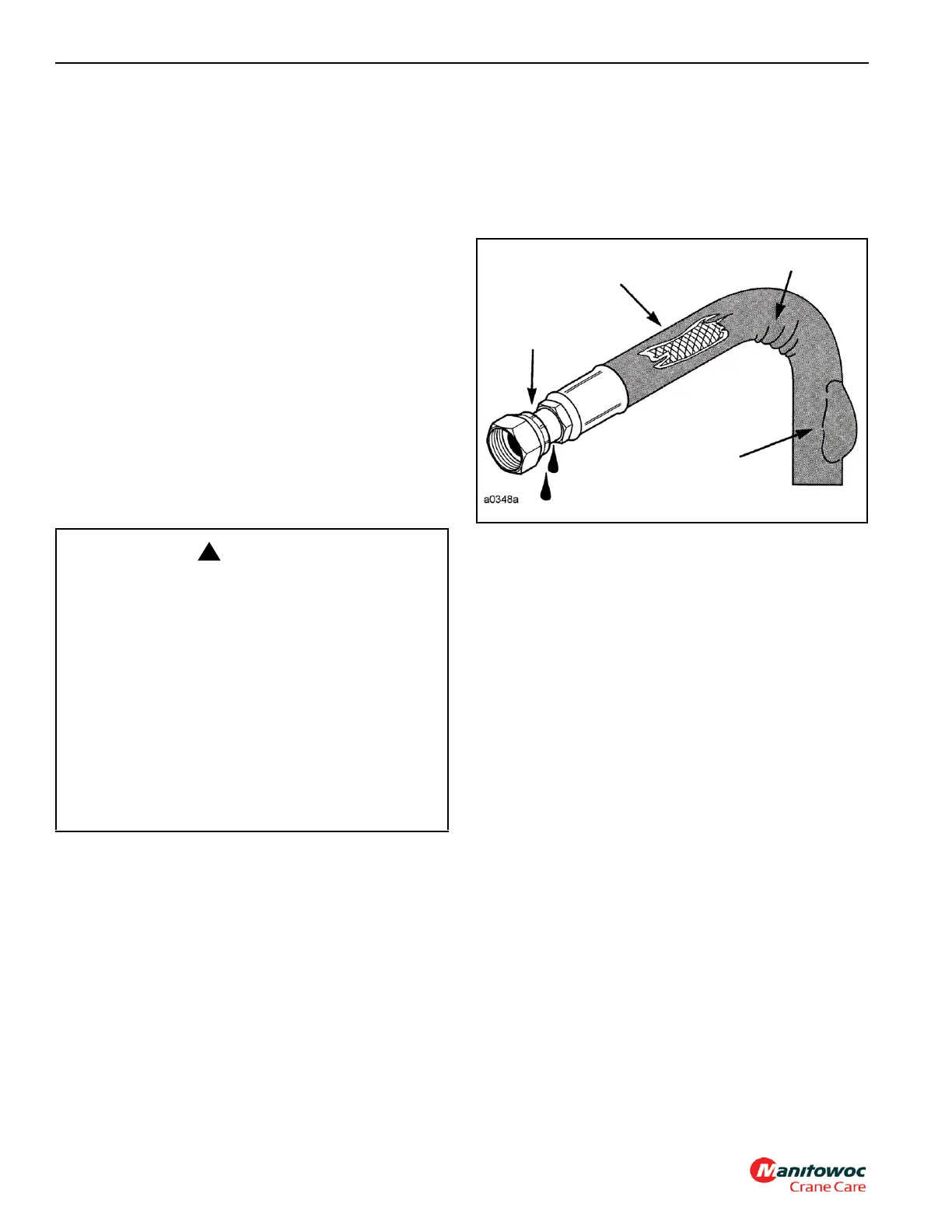

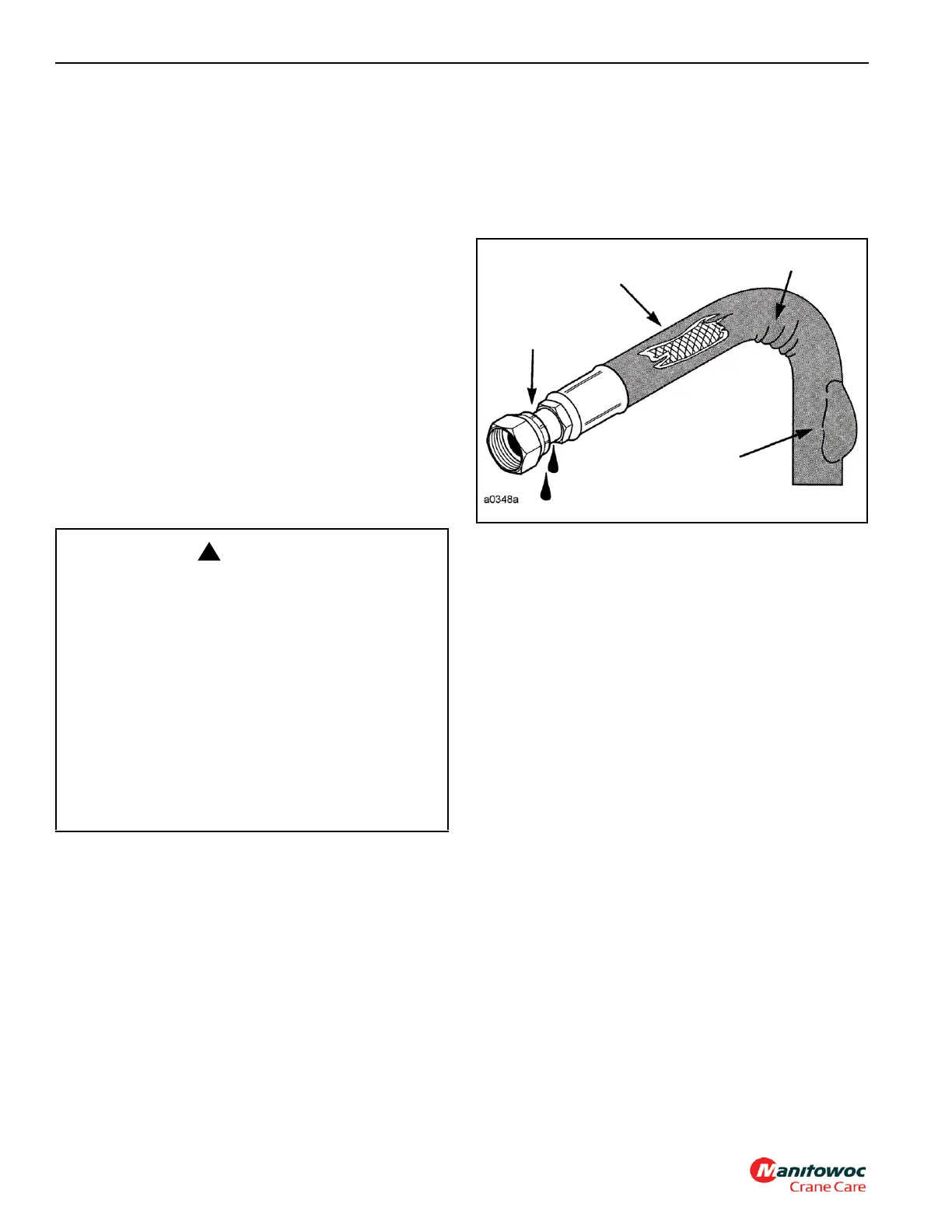

Replace hoses if any of the following is evident Figure 1-4:

• Evidence of kinking or crushing (1)

• Chaffing or cuts; wire is exposed (2)

• Damaged or leaking fittings (3)

• Localized ballooning (4)

Installation

1. When installing a new hose, loosely connect each end

and make sure the hose takes up the designed position

before tightening the connection. Clamps should be

tightened sufficiently to hold the hose without crushing

and to prevent chafing.

2. If a hose is replaced on a part that moves during opera-

tion, be sure it moves freely by moving the part through

its complete range of movement.

3. Be sure any hose which has been installed is not kinked

or twisted.

Free moving, unsupported hoses must never rub on each

other or related work surfaces. This causes chafing and

reduces hose life.

Bearings

Antifriction Bearings

When an antifriction bearing is removed, cover it to keep out

dirt and abrasives. Wash bearings in non-flammable

cleaning solution and allow them to drain dry. The bearing

may be dried with compressed air BUT do not spin the

bearing. Discard the bearings if the races and balls or rollers

are pitted, scored, or burned. If the bearing is serviceable,

coat it with oil and wrap it in clean waxed paper. Do not

unwrap new bearings until time of installation. The life of an

antifriction bearing will be shortened if not properly

lubricated. Dirt in an antifriction bearing can cause the

bearing to lock resulting in the shaft turning in the inner race

or the outer race turning within the cage.

DANGER

High Pressure/Temperature Hazard!

Exercise extreme care around pressurized hydraulic

hoses or tubes. DO NOT work on a hydraulic system

while it is in operation or until all pressure is released.

Hydraulic oil is hot, it can cause severe burns.

Pressurized hydraulic oil can cause death or serious

injury.

Stay clear of all hydraulic oil leaks. Relieve system

pressure and use a piece of cardboard or paper to check

for leaks. Do not use your hands.

Fluid injected into skin must be surgically removed within

a few hours by a doctor familiar with this type of injury or

gangrene will result.

Loading...

Loading...