SWING SYSTEM RT880E SERVICE MANUAL

6-12 Published 11-10-2014, Control # 524-00

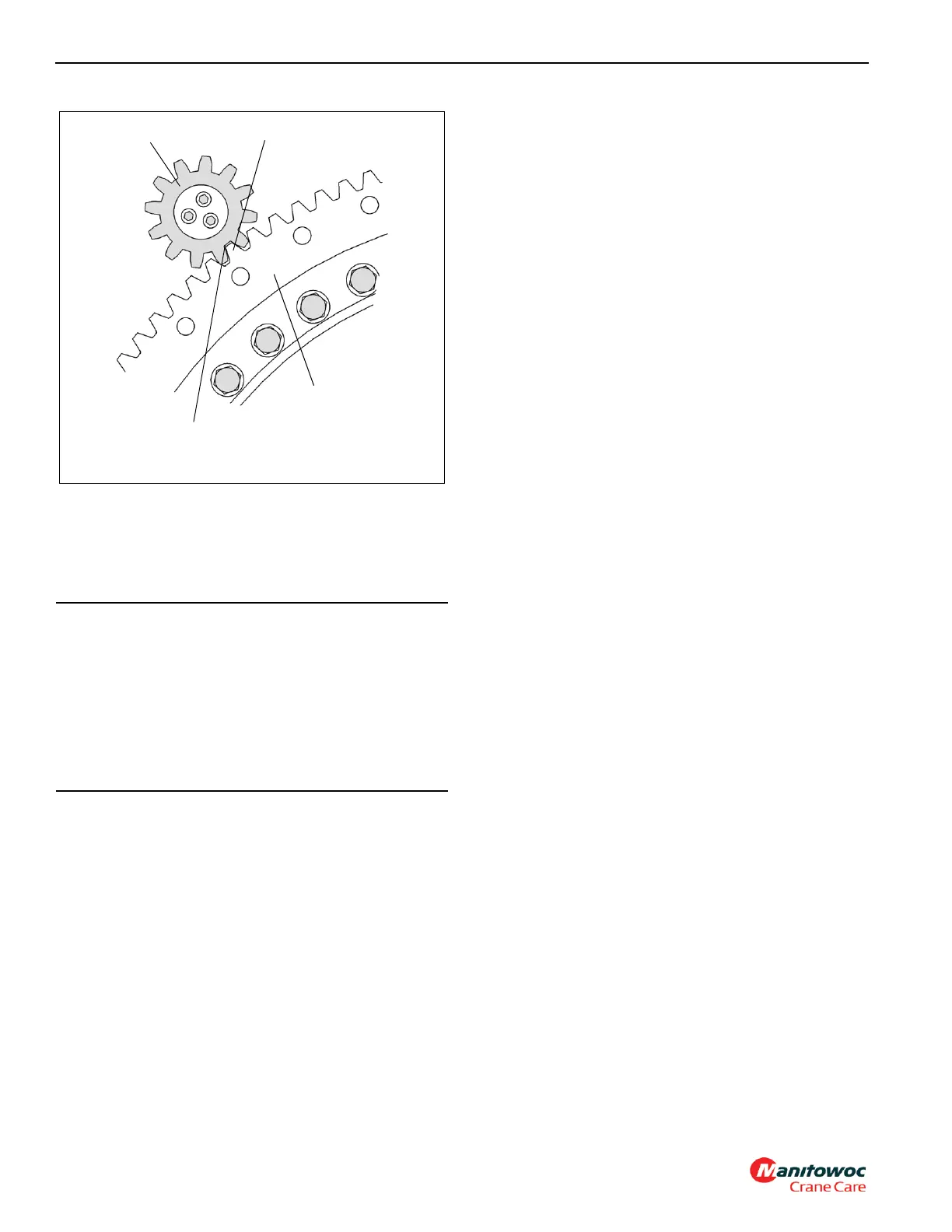

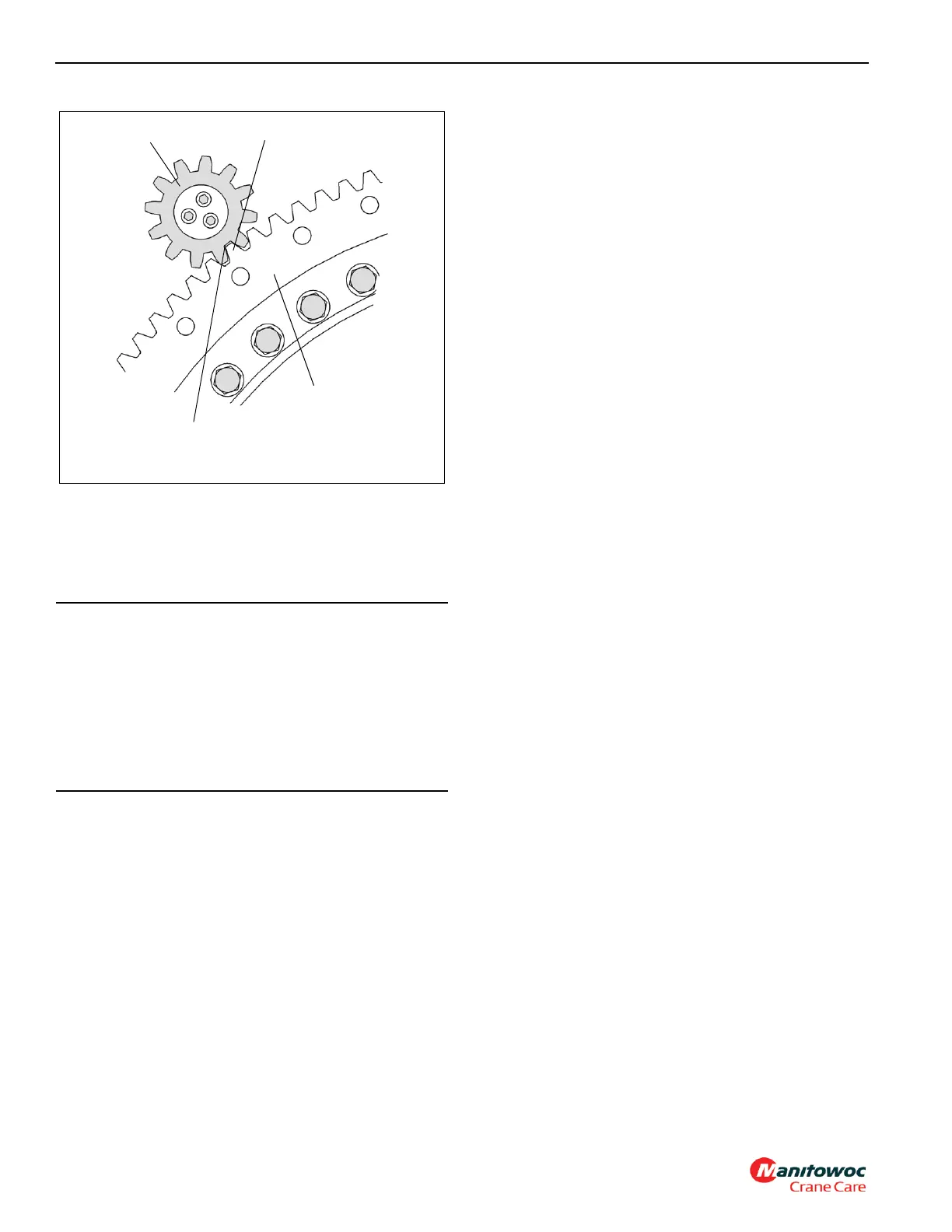

5. Orient ring gear such that its point of max eccentricity

(“high point”) is located between the swing drives. Posi-

tion swing drives so that pinion is centered within cutout

in base plate and motor ports face towards the outboard

side as shown.

6. Position the two retainer plates on the bottom of hydrau-

lic swivel spool, engaging the lugs on the carrier frame,

and secure them to the spool with four bolt retainers and

eight bolts. Torque the bolts to 199 ft-lb (270 Nm). Bend

all the retainer tabs to make contact with the bolt heads.

7. Plug the swivel wiring harness connectors into the car-

rier receptacles. Secure the ground wire to the ground

stud using a washer, lockwasher, and nut.

8. Install the clamp securing the swivel wiring harness to

the retainer plate on the bottom of the hydraulic swivel.

9. Connect all water and hydraulic lines to the ports on the

bottom of the swivel as tagged during removal.

10. Install the boom and lift cylinder following the procedures

outlined in the section titled Boom, page 4-1.

NOTE: The counterweight/auxiliary hoist and structure

weighs approximately 24,398 lb (11067 kg).

11. Install the counterweight and auxiliary hoist following

procedures outlined in Installation of Standard Counter-

weight and Auxiliary Hoist Mounting Structure, page 5-

11.

12. Reconnect the batteries.

13. Check the slew potentiometer in the electrical swivel for

proper orientation. Refer to Swivels, page 6-12.

Testing

Activate the crane and check for proper function.

NOTE: If the superstructure does not turn freely after bear-

ing and pinion replacement, contact your local dis-

tributor.

SWIVELS

Description

The swivel assembly (Figure 6-6) consists of a 12 port

hydraulic swivel, a 2 port water swivel, and a 20 conductor

slip ring electrical swivel. Solid connections cannot be used

to transfer oil, heater hot water and electricity between the

carrier and superstructure due to the continuous 360 degree

swing. The use of swivels efficiently accomplishes this

function.

The barrel portion of the hydraulic swivel is attached to the

turntable base plate by four bolts, washers and bushings.

The spool portion of the swivel rides upon a thrust ring at the

top of the swivel case. The spool portion is held stationary

with the carrier by bolts, and bolt retainer plates attached to

the swivel retainer plate which engages the carrier frame

lugs with bolts and jam nuts. This allows the spool to remain

stationary with the carrier as the case rotates with the

superstructure.

The spool portion of the water swivel is integral with the

hydraulic swivel. The hydraulic and water swivel spools

remain stationary with the carrier as the superstructure

rotates. The water swivel case engages to hydraulic case by

four dowel pins.

The electrical swivel center or collector ring assembly is

secured by setscrews to a center post which is bolted to the

spool of the hydraulic swivel. This allows the collector ring

assembly to remain stationary with the carrier. The outer

portion or brush assembly is mounted on two studs which

are located on the mounting plate assembly which is

retained to the water swivel barrel by a bolt. This allows the

brush assembly to rotate with the superstructure around the

stationary collector core.

CAUTION

Do Not Clamp Over Pinion.

• Using shims, set backlash by moving the swing drive

assemblies toward the bearing in order to mesh the

pinion with the ring gear teeth (see Figure 6-5).

• Check tooth engagement squareness and vertical

tooth engagement.

• Remove backlash shims and recheck backlash.

FIGURE 6-5

Maximum Eccentricity Point

.008 Thick Shim By Full Width to

Tooth Engagement (.016)

Backlash)

Pinion

6492

Bearing

Loading...

Loading...