Grove Published 11-10-2014, Control # 524-00 9-23

RT880E SERVICE MANUAL LUBRICATION

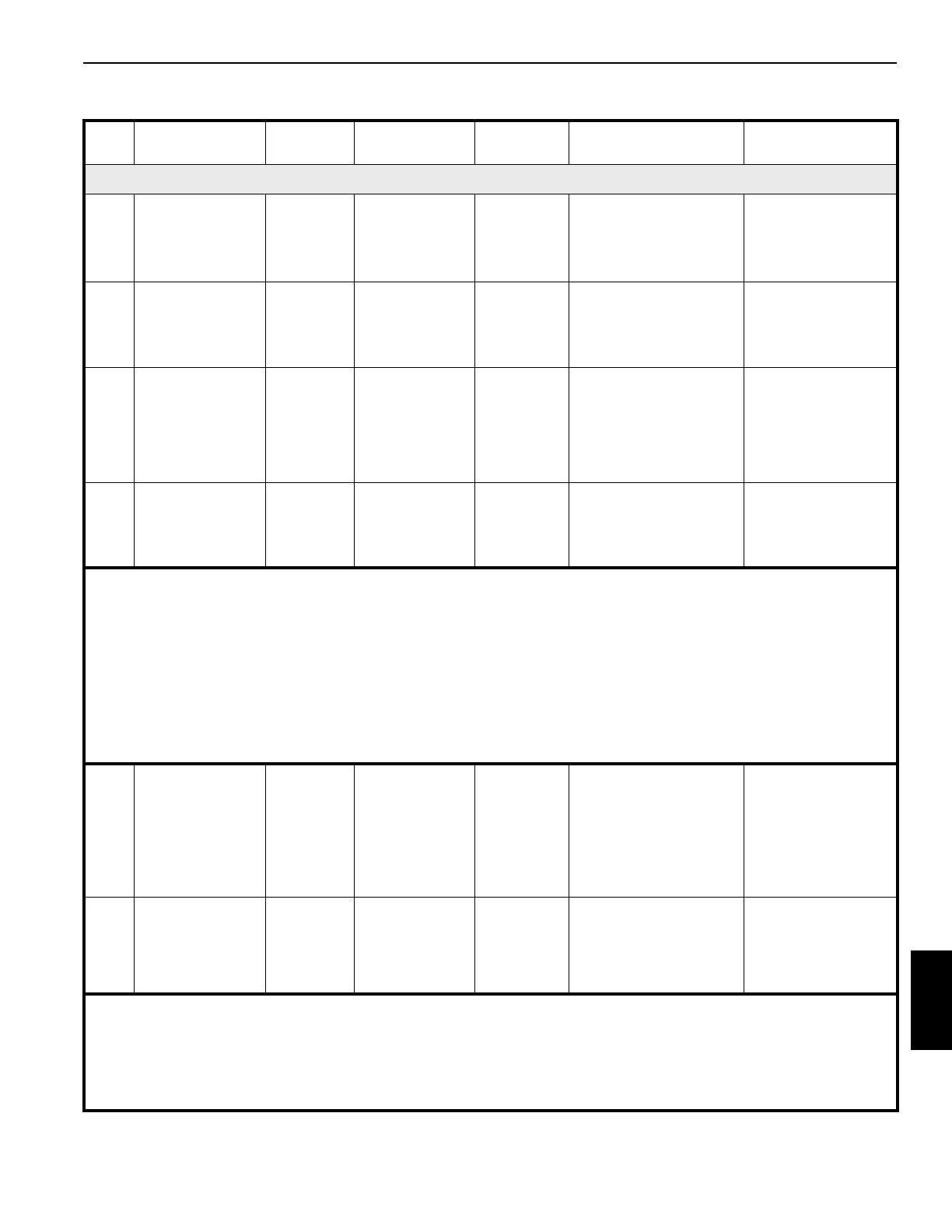

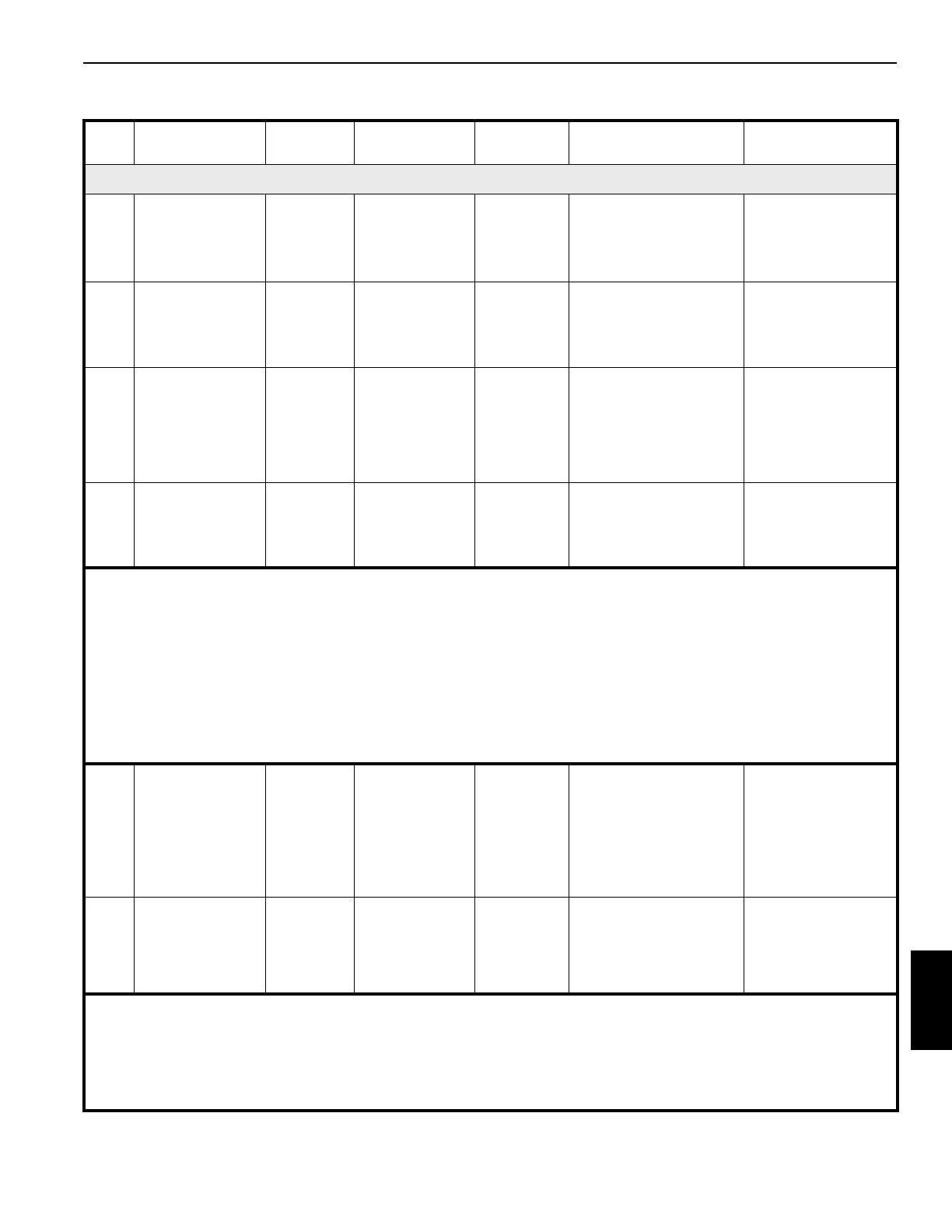

Item

Lube Point

Description

Figure

No.

Approved

Lubricant

Lube

Capacity

Lube Interval Application

Boom

70

Hook Block

Swivel Bearing

Figure 9-8

EP-MPG

Extreme Pressure

Multipurpose

Grease

6829003477

Until

grease

extrudes

250 hours or 3 months 1 grease fitting

71

Hook Block

Sheaves

Figure 9-8

EP-MPG

Extreme Pressure

Multipurpose

Grease

6829003477

Until

grease

extrudes

250 hours or 3 months

1 grease fitting per

sheave (5 fittings

total)

72 Headache Ball Figure 9-8

EP-MPG

Extreme

Pressure

Multipurpose

Grease

6829003477

Until

grease

extrudes

250 hours or 3 months 1 grease fitting

73

Telescope

Cylinder Wear

Pads

Figure 9-8

EP-MPG

Extreme Pressure

Multipurpose

Grease

6829003477

Thoroughly

coat

Every boom teardown 5 places by brush

NOTE:

• For service of the boom, that is to be extended greater than 120 ft, the counterweight must be installed on the turntable and the

outriggers must be fully extended. Superstructure could be in any slew position. No rigging, no hookblock nor overhaul ball may

be installed on the nose of the boom. Extend boom to desired length at a boom angle of 20°. Lower boom until RCL limits the

boom lower function. Override RCL per RCL operators manual and lower boom to desired angle.

• Should boom chatter or rubbing noises in the boom occur, it will be necessary to lubricate the telescope cylinder wear

pads. By adding an extension adapter to a grease gun the wear pads and wear areas can be reached through the

lubrication access holes in the side of the boom and through the access hole in the boom nose between the sheaves.

• Lubricate more frequently than interval indicated in table if environmental conditions and/or operating conditions

necessitate.

74

Internal Side and

Bottom Wear

Pads (Inner

Sections)

Figure 9-8

EP-MPG

Extreme Pressure

Multipurpose

Grease

A6-829-003477

Thoroughly

coat all

areas the

wear pad

moves on

250 hours or 3 months

14 places by brush;

with boom in

extended position

through access

holes in inner-mid

and outer-mid

sections

75

Boom Section

Upper Wear

Pads

Figure 9-8

EP-MPG

Extreme Pressure

Multipurpose

Grease

A6-829-003477

Until

grease

extrudes

50 hours or 1 week

8 grease fittings;

with boom in

extended position

through access

holes

• For service of the boom, that is to be extended greater than 120 ft, the counterweight must be installed on the turntable and the

outriggers must be fully extended. Superstructure could be in any slew position. No rigging, no hookblock nor overhaul ball may

be installed on the nose of the boom. Extend boom to desired length at a boom angle of 20°. Lower boom until RCL limits the

boom lower function. Override RCL per RCL operators manual and lower boom to desired angle.

• Lubricate more frequently than interval indicated in table if environmental conditions and/or operating conditions

necessitate.

Loading...

Loading...