HYDRAULIC SYSTEM RT880E SERVICE MANUAL

2-12 Published 11-10-2014, Control # 524-00

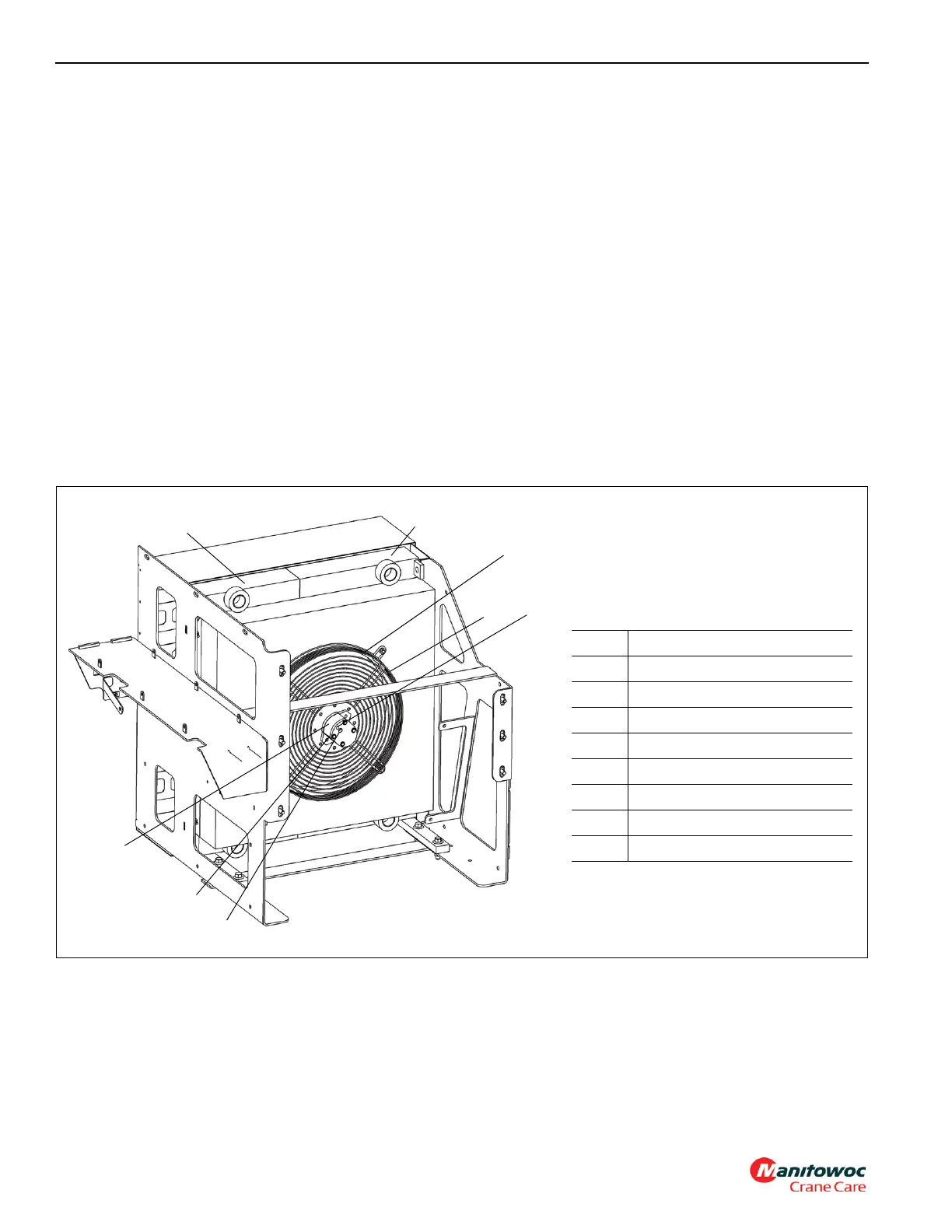

Oil Cooler

An air cooled oil cooler (see Figure 2-5) is located on the left

side of the crane and consists of a transmission oil cooler

and a hydraulic oil cooler.

The fan pulls cool air through the cooling fins on the coolers.

Normally, most hydraulic oil from components is routed

through the oil cooler by way of a return line and on to the

filter in the reservoir. When several hydraulic functions are

being used at one time (i.e., hoisting, lifting, and

telescoping), more oil has to flow through this return line,

causing a pressure buildup. When this pressure reaches

15 psi (103.4 kPa), the normally closed check valve in the

return line (in parallel with the return line through the

hydraulic oil cooler) will open, letting some hydraulic oil

bypass the hydraulic oil cooler and flow directly into the

reservoir filter.

When fewer functions are being used, the pressure in the

system will decrease below 15 psi (103.4 kPa) and the

check valve will close again.

A temperature switch (15, Figure 2-3), located in the tube

that routes return oil to the hydraulic oil return filter in the

reservoir, is part of a circuit that controls the oil cooler fan

motor. The switch is normally closed and will open and cause

the circuit to lose ground when the hydraulic oil temperature

exceeds 120°F (48.8°C). When the circuit loses ground, the

CAN bus system will de-energize the oil cooler solenoid

valve, allowing pressurized oil from Pump No. 1 to flow to the

oil cooler fan motor.

A second temperature switch located in the inlet tube of the

transmission oil cooler, is part of a circuit that will alert the

operator to a high transmission oil temperature condition.

The switch is normally closed and will open and cause the

circuit to lose ground when the transmission oil temperature

exceeds 200°F (93°C). When the circuit loses ground, the

CAN bus system will turn on power to illuminate the

Transmission Warning Indicator in the gauge display in the

operator’s cab. See Section 3 - Operating Controls and

Procedures, in the Operator Manual for details of the

Transmission Warning Indicator.

FIGURE 2-5

Item Description

1 Transmission Oil Cooler

2 External Drain Port

3Fan

4 Hydraulic Oil Cooler

5 Inlet Port

6 Motor

7 Shroud

8Outlet Port

1

2

3

4

5

6

7697

7

8

Loading...

Loading...