HOISTS AND COUNTERWEIGHT RT880E SERVICE MANUAL

5-4 Published 11-10-2014, Control # 524-00

Functional Check

1. Attach a test weight to the hook and raise and lower the

load several times.

2. Check the hoist for smooth operation of the hoist motor

and brake system.

3. Ensure the hydraulic connections are secure and free

from leaks.

Fluid Level

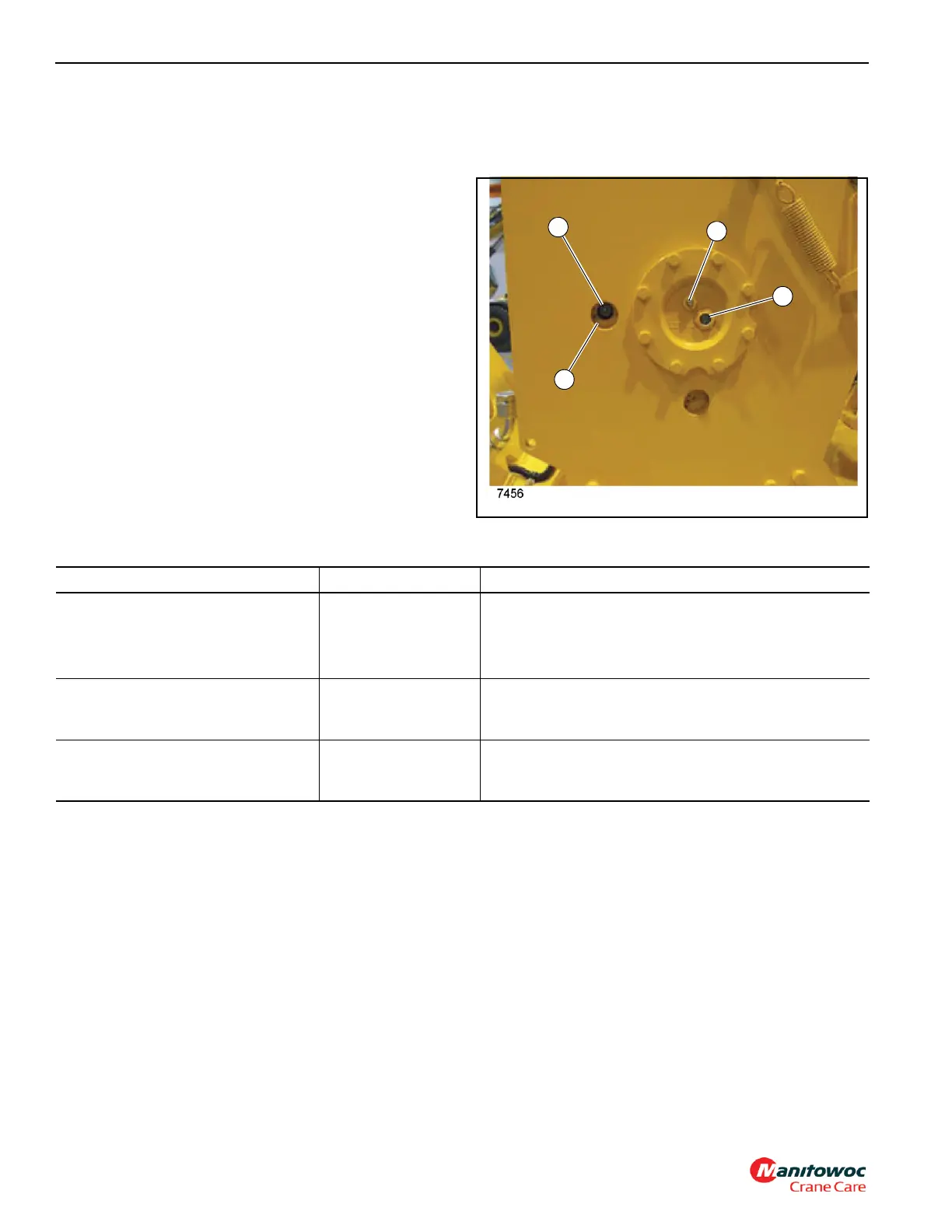

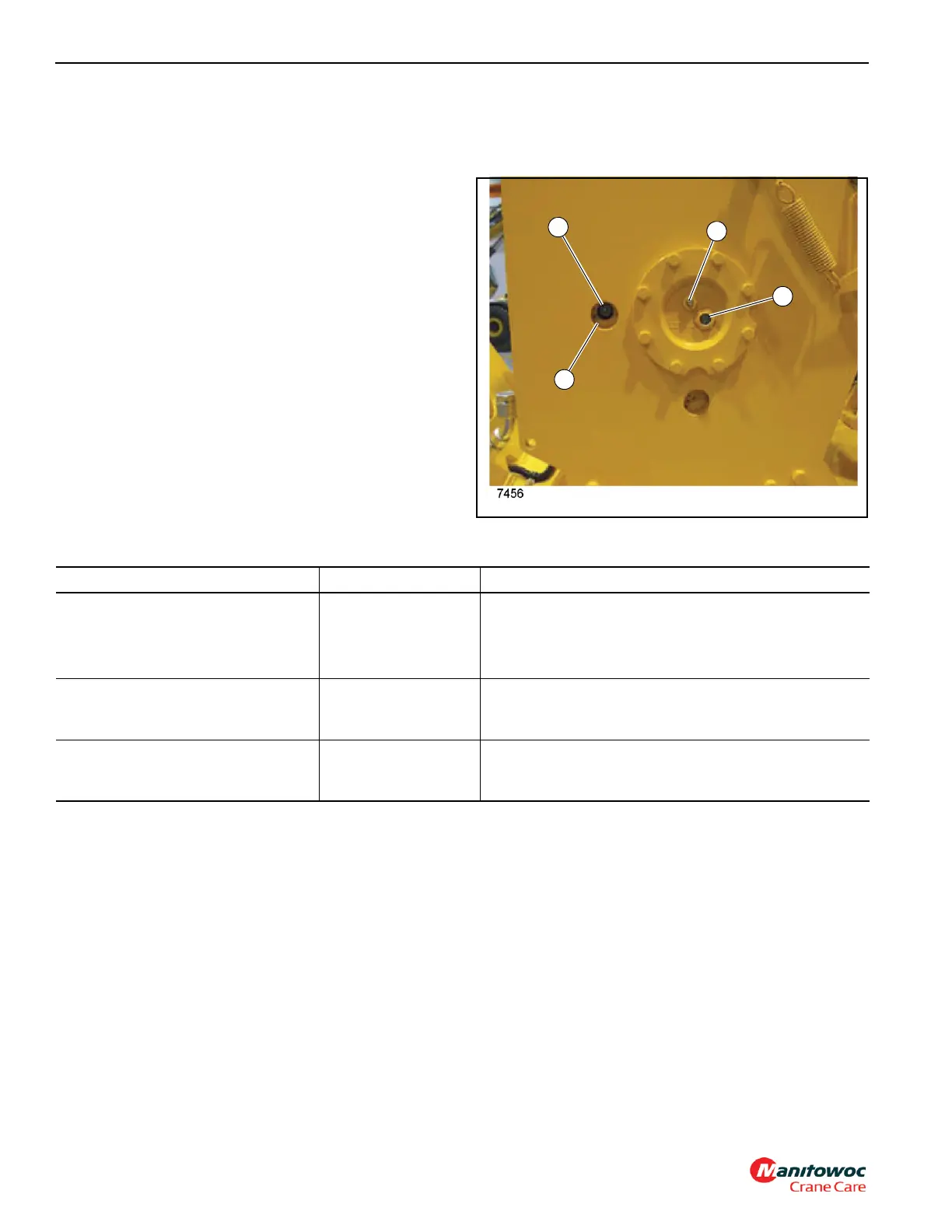

NOTE: Failure to align the fill/drain plug (1) with the upper

access hole (2) as shown in Figure 5-2 prior to

checking the oil level will result in an inaccurate

reading.

1. Rotate the hoist drum until the fill/Drain plug (1) appears

in the upper access hole (2) shown in Figure 5-2.

This will ensure that the planetary gears are in proper

alignment and will permit an accurate reading of the oil

level in the hoist.

2. Allow the hoist to stand idle for 20 minutes before check-

ing the oil.

3. The oil level should be visible in the sight glass (3).

Compare your reading with Table 5-1 below and take the

required action.

Table 5-1

Reading Diagnosis Action Required

Oil is not visible in the sight glass.

The hoist is under

filled.

Fill the hoist with oil from the upper access hole until the

oil level rises within the sight glass. Do not fill above 1/8”

(3 mm) from the top of the site glass.

Refer to Hoist, page 9-29 for the correct type of oil.

Oil is visible in the sight glass and the

level is no more than 1/8” (3 mm) from

the top of the sight glass.

The oil level is

correct.

No action is required.

Oil level is more than 1/8” (3 mm)

from the top of the sight glass or the

oil is escaping from the vent plug (4).

The hoist is overfilled.

Drain the hoist drum from the upper access hole until the

oil level falls to within 1/8” (3 mm) from the top of the sight

glass.

Loading...

Loading...