Grove Published 11-10-2014, Control # 524-00 6-15

RT880E SERVICE MANUAL SWING SYSTEM

NOTE: The hydraulic swivel weighs approximately 213 lb

(97 kg). The hydraulic, water, and electrical swivel

combined weigh approximately 239 lb (108 kg).

9. On the bottom of the swivel, bend the retainer tabs away

from the bolt heads. Remove the capscrews and cap-

screw retainers securing the two retainer plates to the

spool. Remove the retainer plates from the spool and

the lugs on the carrier frame.

NOTE: It may be necessary to remove some drive line

components to remove the swivel.

10. Position an adequate supporting device beneath the

swivel.

11. Remove the capscrews, washers, and bushings secur-

ing the swivel barrel to the turntable base plate and

lower the swivel to the ground.

Installation

NOTE: The hydraulic swivel weighs approximately 213 lb

(97 kg). The hydraulic, water, and electrical swivel

combined weigh approximately 239 lb (108 kg).

1. Raise the swivel into position.

2. Secure the hydraulic swivel to the turntable base plate

with the bushings, capscrews and washers. Torque cap-

screws; refer to Fasteners and Torque Values, page 1-

15 for proper torque value.

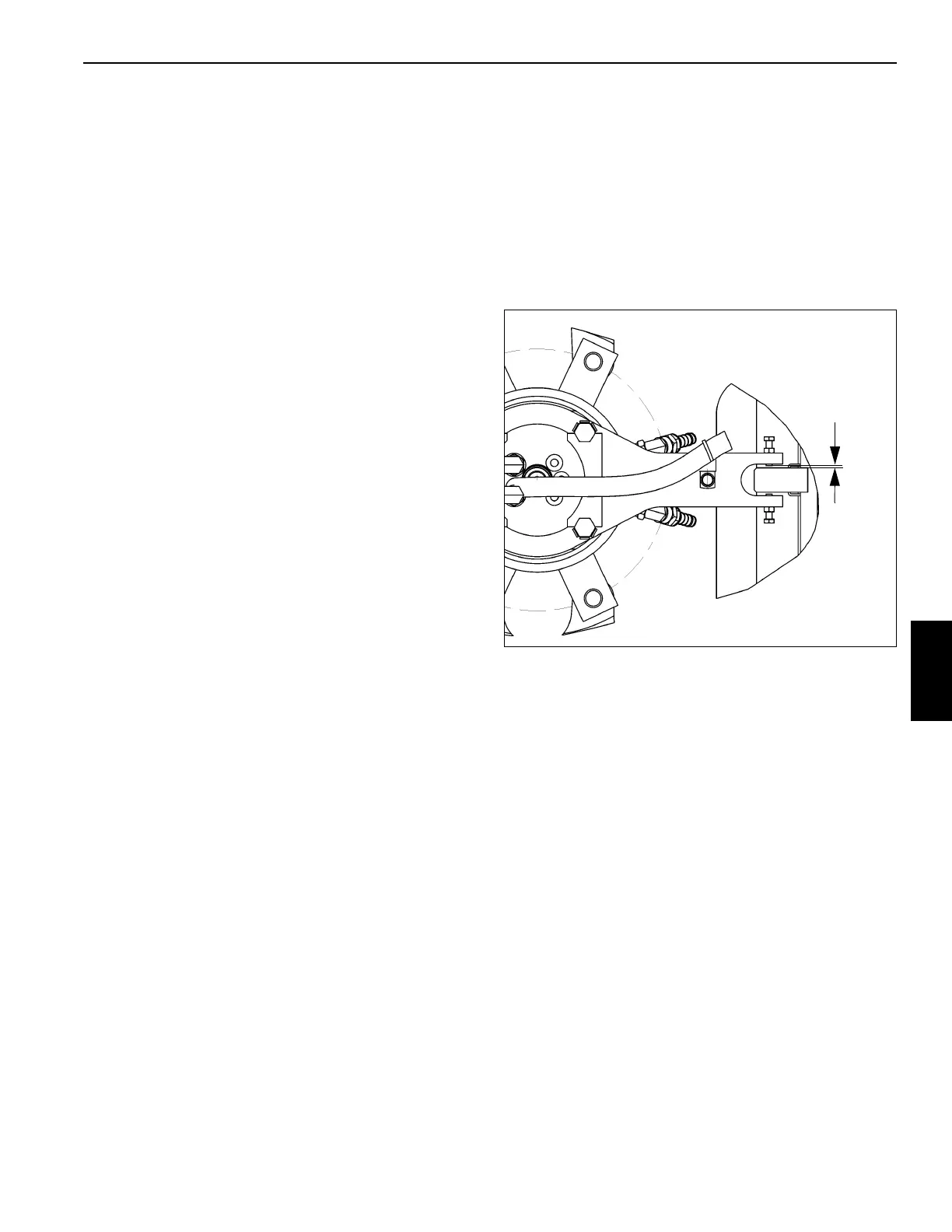

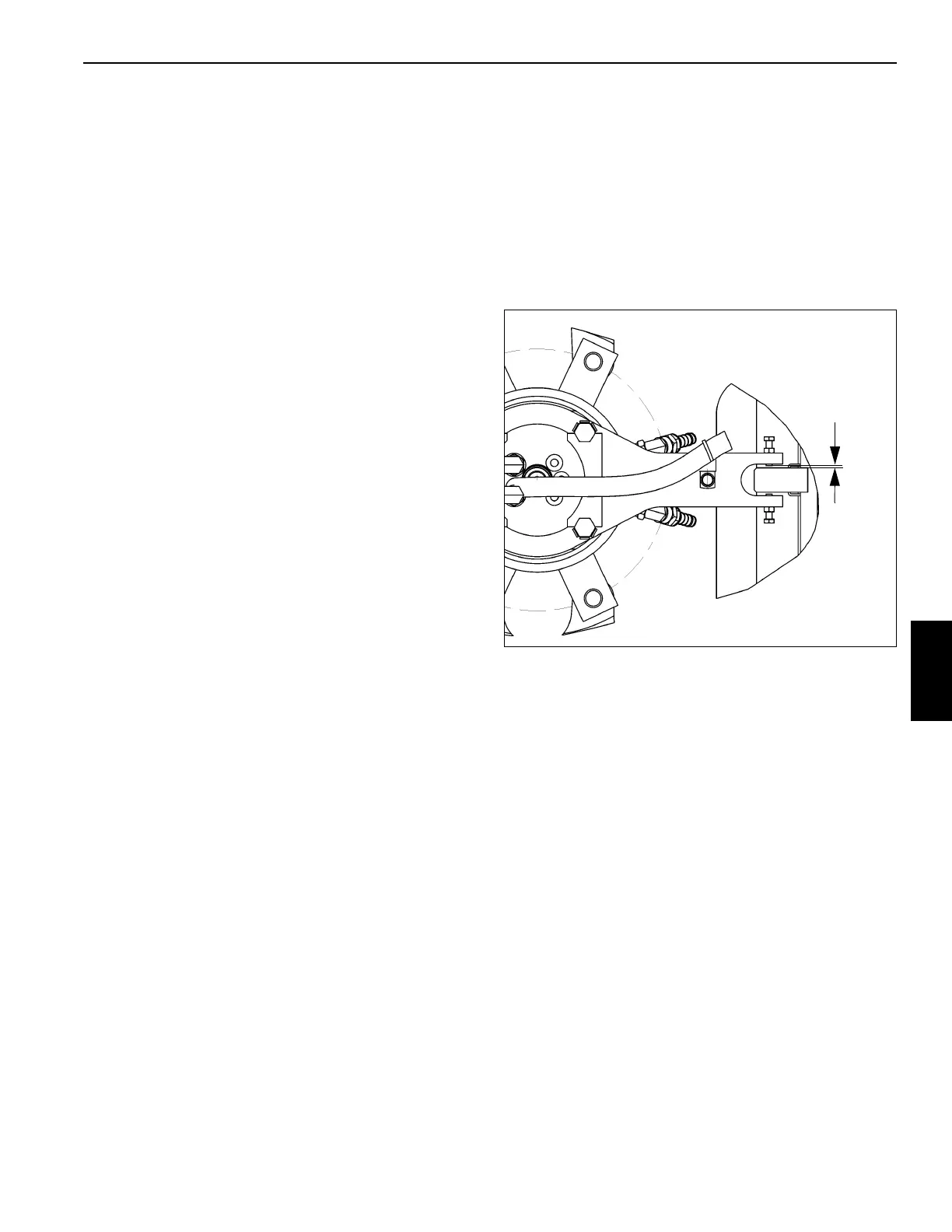

NOTE: Allow a 1/32' (1 mm) max gap between bolt and the

retaining lug on the frame. Do not tighten bolt

against lug (Figure 6-7).

3. Position the two retainer plates on the hydraulic swivel

spool ensuring they engage the lugs on the carrier

frame. Secure the retainer plates with the capscrews

and capscrew retainers. Apply Loctite® 271 to the bolt

threads. Torque the bolts 199 lb-ft (270 Nm). Bolt head

flats must align with retainer tabs. Bend all the retainer

tabs to make contact with the bolt heads. Snug the

retainer plate capscrews against the lugs on the carrier

frame and tighten the locking nuts.

4. If removed, install the electrical swivel. Refer to Electri-

cal Swivel, page 6-16. Connect the swivel wiring har-

ness connectors to the carrier receptacles and the

ground wire to the mounting bracket on the carrier

frame. Use the bolt and star washers taken off at

removal. Make sure the ground connection is clean and

has good metal to metal contact. Spray the connection

with a battery terminal protectant such as Deka Battery

Terminal Protection spray, Grove P/N 9999102423.

5. Install the clamp, lockwasher, flat washer and capscrew

to the bottom of the swivel retainer plate securing the

wiring harness.

6. Connect the hydraulic lines and water lines to the spool

of the hydraulic swivel as tagged during removal.

7. Connect the hydraulic lines to the hydraulic swivel case

as tagged during removal.

8. Connect the water lines to the water swivel case as

tagged during removal.

9. Remove the blocking material from the lift cylinder.

10. Activate all systems; cycle all functions and observe for

proper operation and any leakage.

Two Port Water Swivel

Description

The two port water swivel allows engine coolant to flow from

the carrier-mounted engine to the hot water heater in the

operator’s cab. Through an internally drilled passage in the

14 port hydraulic swivel spool, coolant is transferred to a

circumferential groove on the water spool exterior. This

groove corresponds with a mating port on the outer case of

the water swivel. The spool grooves are separated by a quad

ring/telflon bronze ring seal. The lip seal prevents coolant

from leaking externally. Return engine coolant flow from the

hot water heater is accomplished in the same manner

through the opposite port of the water swivel.

Maintenance

Removal

1. Perform steps 1 thru 4 of the removal procedure under

Hydraulic Swivel, page 6-14.

2. Remove the electrical swivel. Refer to removal proce-

dure under Electrical Swivel, page 6-16.

3. Tag and disconnect the lines from the case of the water

swivel. Cap or plug all lines and openings.

FIGURE 6-7

1.0 mm

(0.031 in)

Loading...

Loading...