It is recommended that a sizing die with the decapping rod removed be used to hold down the cases in

station 4 in order to center the case over the priming punch and to provide additional support to the

cases during primer insertion. Thread the sizing die all the way down so that it just starts to touch the

shell plate and lock the die in place. Always use case lube when resizing once fired cases. Note: Lube is

recommended with pistol caliber tungsten carbide dies to ensure smooth operation. All rifles cases

MUST be lube prior to sizing.

Run a few cases through the sizing die and check cases using a sizing gauge to confirm they are being

sized properly. For rifle calibers, we strongly suggest the use of a headspace gauge to verify proper case

headspace. The sizing die should be adjusted up or down in the die station to correct headspace.

WARNING – Never install more than 100 Primers at once. Always wear protective eyewear and hearing

protection when loading primers into the machine and loading. Activities using the Mark 7® APEX 10

TM

are inherently dangerous and may lead to injury and even death.

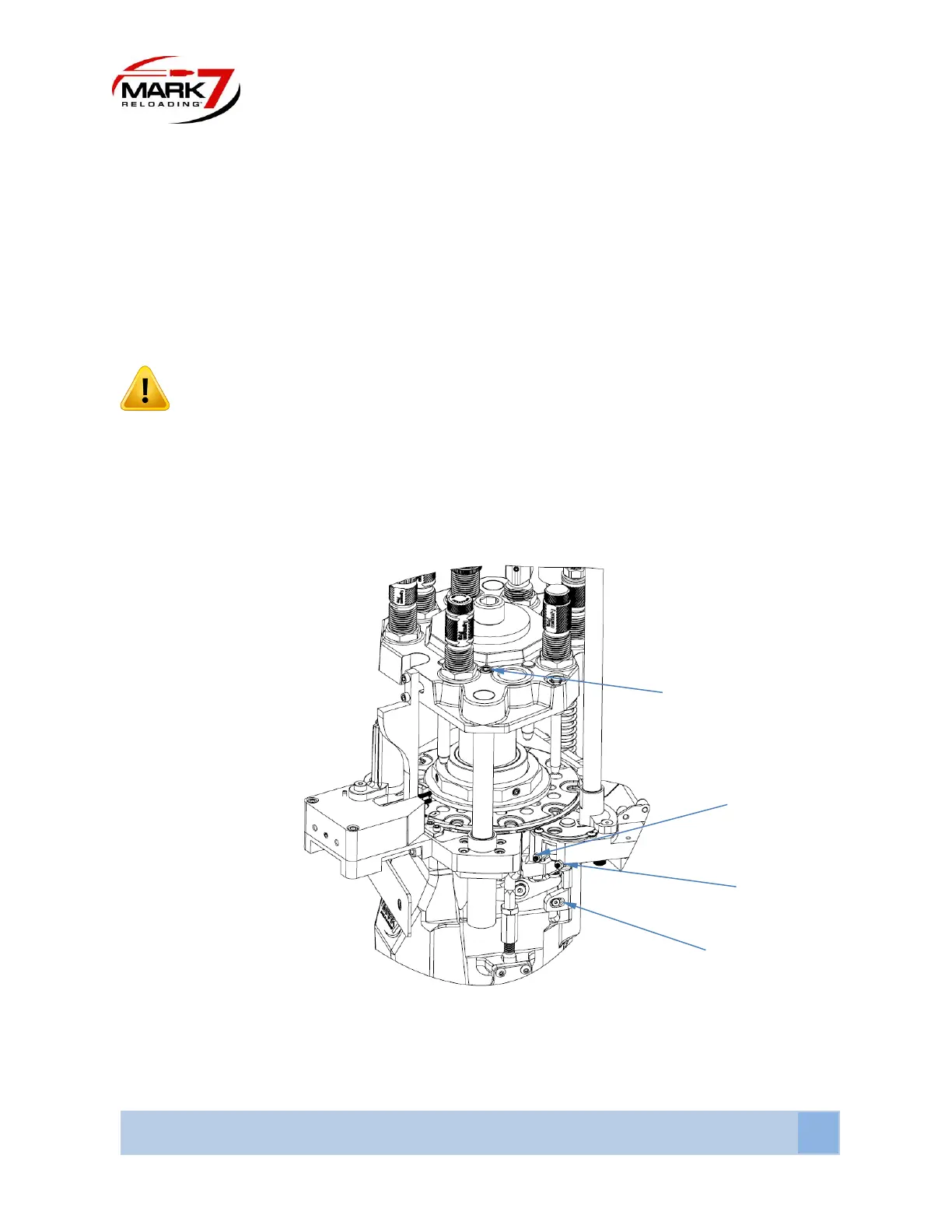

Figure 17: Primer Adjustments

Loading...

Loading...