Shell Plate Indexing Adjustments

It is important to check the indexing adjustment whenever performing routine press maintenance.

There are 3 main adjustments points /areas to check:

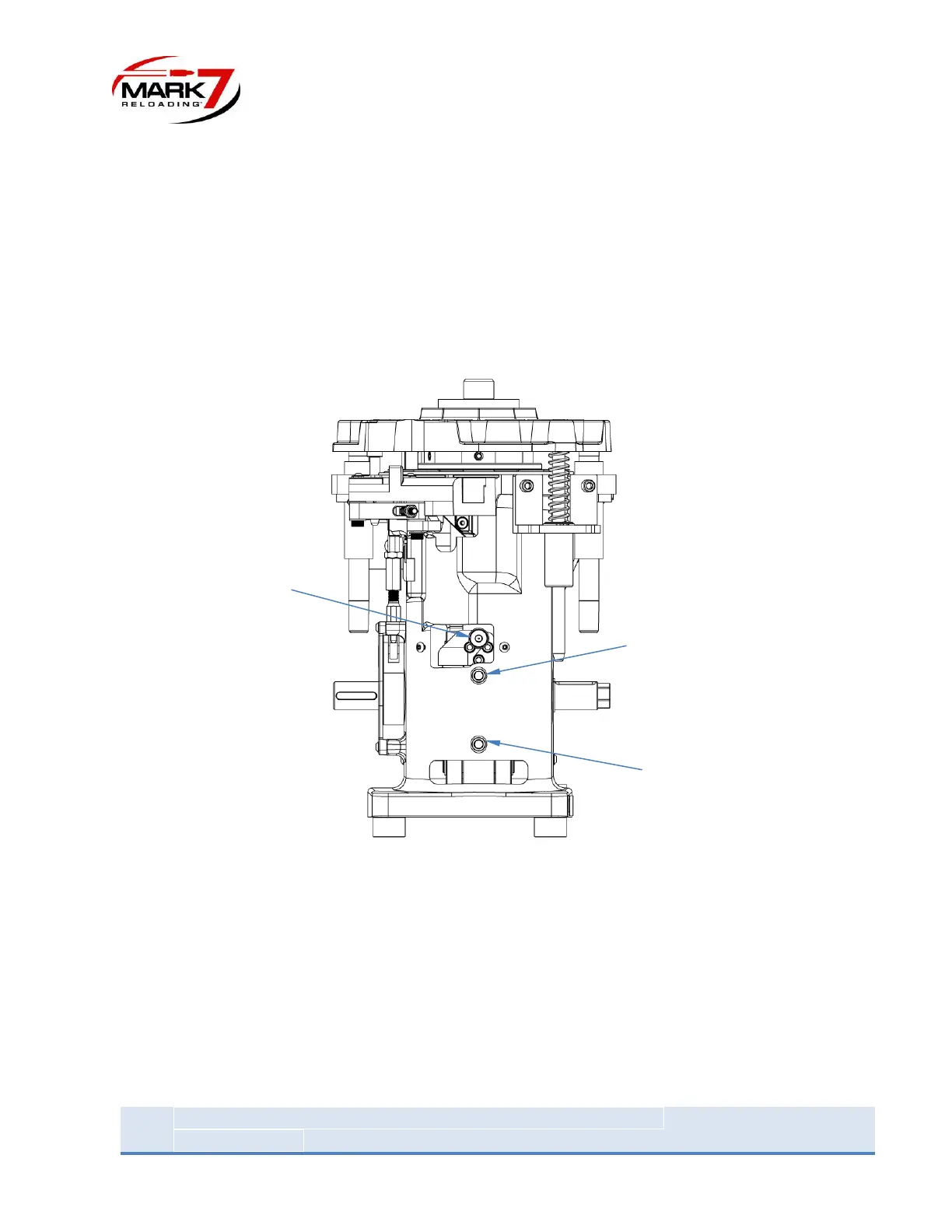

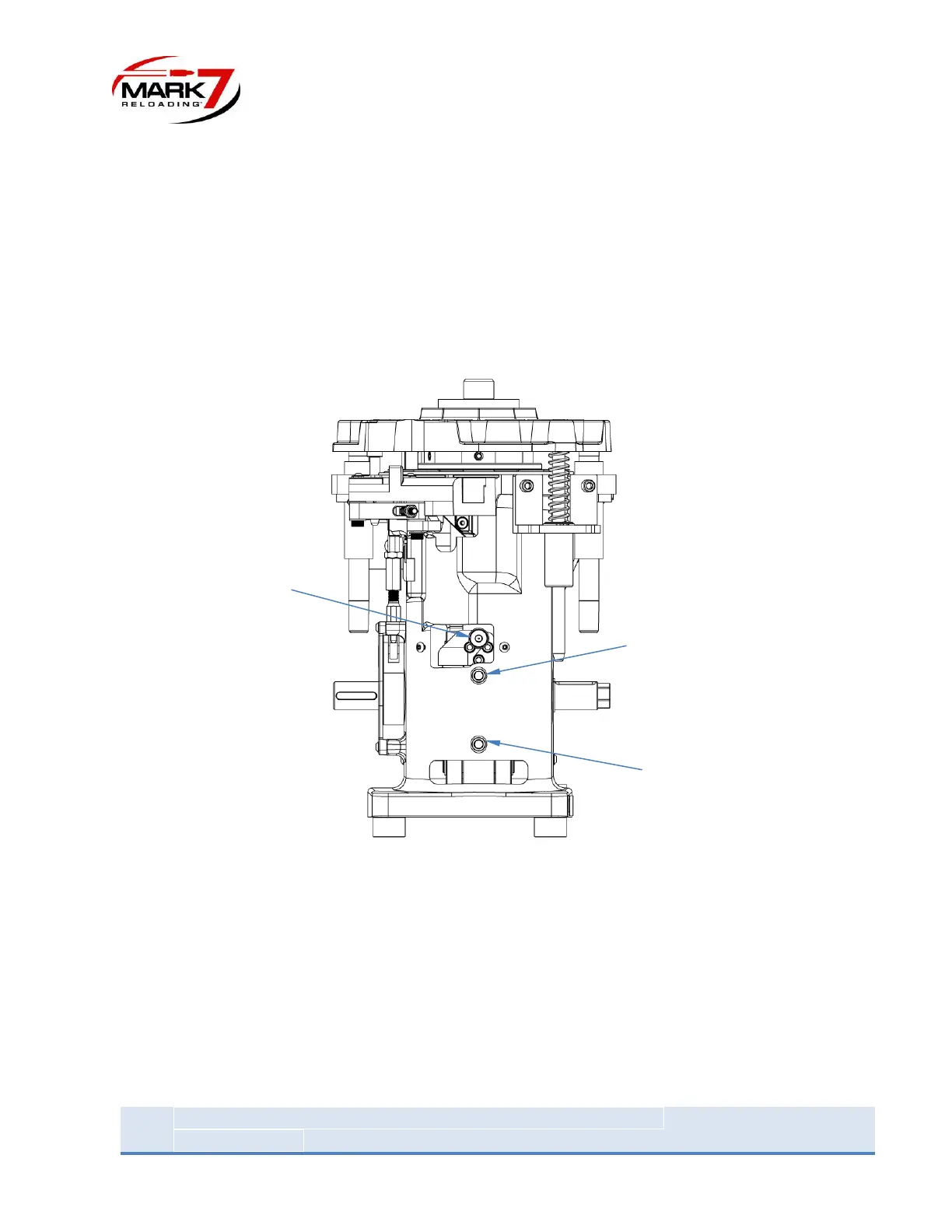

1. Crank Upper Stop Limit- This sets the upper position of the stroke of the machine and is

adjusted via the upper set screw on the rear of the machine as shown in the figure below. If this

comes out of adjustment the machine may start indexing too far or not far enough – It’s

important to check the position of the setscrew and make sure the jam screw is locked in place.

2. Index Cam Bearing - Check Mount and bearing for tightness – keep grease on bearing surface

Figure 24: Rear of Press – Crank Stop Adjustments

3. The Index Pawl is factory set to give proper indexing of the shell plate. Adjustment of the Index

Pawl should only be made if the shell plate is not lining up properly with the alignment pins. If

adjustment is needed, insert a 5/64” hex wrench into the adjustment screw located inside the

access hole on the upper left hand side of the press. See figure #24. Turning the screw clockwise

will move the shell plate in a counter clockwise direction. Turning the screw counter clockwise

will move the shell plate in a clockwise direction. Turn the screw about a 1/8 turn at a time and

cycle the press to check for alignment of the plate and alignment pins. Make this adjustment

with no cases on the shell plate.

Loading...

Loading...