Installation

27 0000000141 - 002 - EN

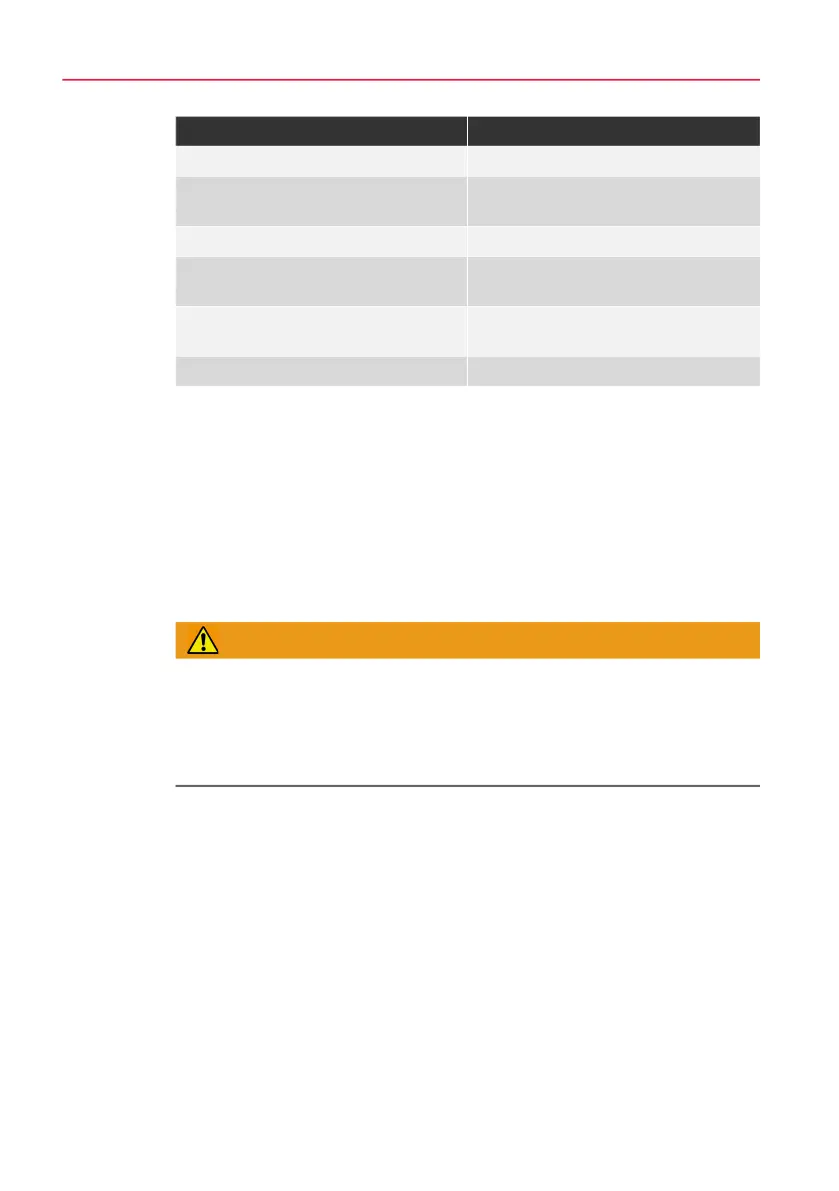

Tab. 5-2 Calculation of the stall pressure

Legend:

p

L

= drive pressure

p

B

= operating pressure

p

A

= primary gas pressure

i = pressure ratio

i

1

= pressure ratio stage 1

i

2

= pressure ratio stage 2

5.4.2 Commissioning

WARNING

Risk of injury due to extreme temperatures!

The surfaces of the product can be very hot or very cold. This can lead to acci-

dents resulting in severe injuries or death.

► Before working on the product, please ensure that the product is at ambient

temperature.

Details about the commissioning of the gas booster are described below:

1) Check all connections for proper installation.

2) Check all connecting lines for mechanical damage.

3) Slowly open the supply line.

– The compressed fluid flows in.

4) If applicable, open the control air line.

5) Slowly open the compressed air line of the compressed air line system to the

gas booster.

– The gas booster automatically starts to compress the gas.

Gas booster design Standstill pressure

Single-stage, single-acting p

B

= p

L

* i

Single-stage, double-acting / quadru-

ple-acting

p

B

= i * p

L

+ p

A

Two-stage p

B

= i

2

* p

L

+ i

2

/ i

1

* p

A

Single-stage, single-acting with two

drive parts

p

B

= p

L

* i

Single-stage, double-acting / quadru-

ple-acting with two drive units

p

B

= i * p

L

+ p

A

Two-stage with two / three drive units p

B

= i

2

* p

L

+ i

2

/ i

1

* p

A

Loading...

Loading...