Maintenance

35 0000000141 - 002 - EN

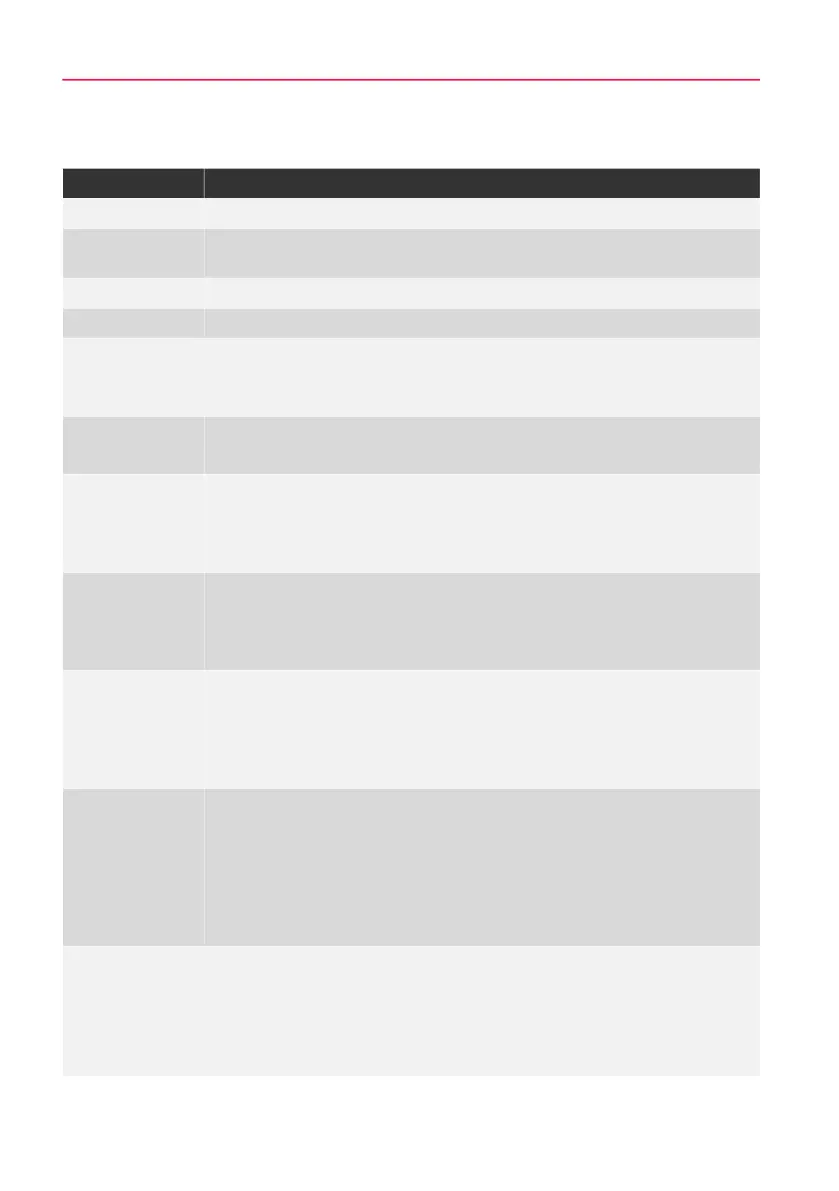

7.2.6 Leak detection

The following section explains how to inspect for leaks:

Description

Qualifications Repair and service gas booster

Type of mainte-

nance

Check

Interval semi-annually

Prerequisites The gas booster is easy to access.

Tools – Torch

– Leak detection system

a

– Jaw spanner

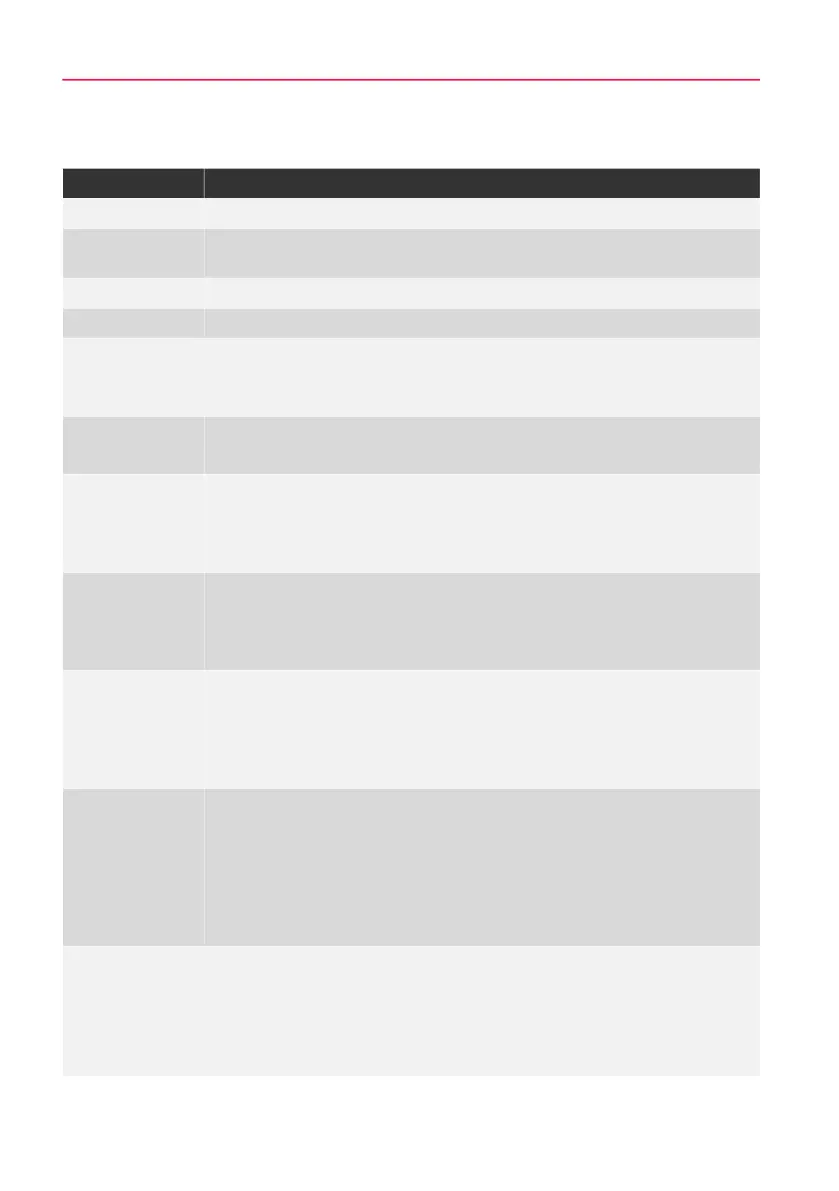

1. On a running gas booster (about 40 strokes/min, clear outlet):

Test for leaks on the drive side (Z2, Z4, Z6).

2. Shut off the gas outlet.

Adjust p

B

to a value that is standard for the system.

Relieve p

L

.

Test for leaks on the high pressure side (Z1, Z3).

b

3. Carefully relieve the gas outlet until the gas booster piston has reaches its

end position and the other cylinder is pressurized .

Shut off the gas outlet.

Test for leaks on the high pressure side (Z1, Z3).

c

4. Shut off the gas outlet.

p

B

to a value that is standard for the system.

Relieve p

A

.

Relieve p

L

.

Measure leakage via the check valves.

5. Relieve p

L

.

Relieve p

A

.

Relieve p

B

.

Disassemble the spool valve.

Examine the spool valve.

Are the seals worn?

Is it still adequately lubricated?

6. The inspection has been successful if:

– all leak tests have been carried out successfully.

– the spool valve is OK.

If the gas booster does not pass the inspection, it must be repaired or re-

placed.

Loading...

Loading...