Use in explosion-prone zones

47 0000000141 - 002 - EN

* With these gas boosters, the volume flows are only required during commis-

sioning and decommissioning.

** Purging is not possible with these gas boosters.

In addition to the volume flow of the purging gas, the cross-sections of the purg-

ing line are also important. It is recommended that internal diameters are never

below 4 mm. If this diameter is less than 4 mm, a risk will be posed that gas pres-

sure will develop in the purging line. This may potentially cause damage to the

high pressure part of the gas booster.

Furthermore, ensure that the outlet of the purge line is clear.

10.4.2 Alternative purging options for the compression of combustible gases

As an alternative to the process described for purging the gas booster with nitro-

gen, any other process with the properties listed below is suitable to ensure safe

operation.

– Always purge the gas booster in a way that no ignitable mixture can form in

the leakage chamber.

– No negative pressure may occur in the leakage chamber.

– A maximum excessive pressure of 0.5 bar must not be exceeded in the leak-

age chamber.

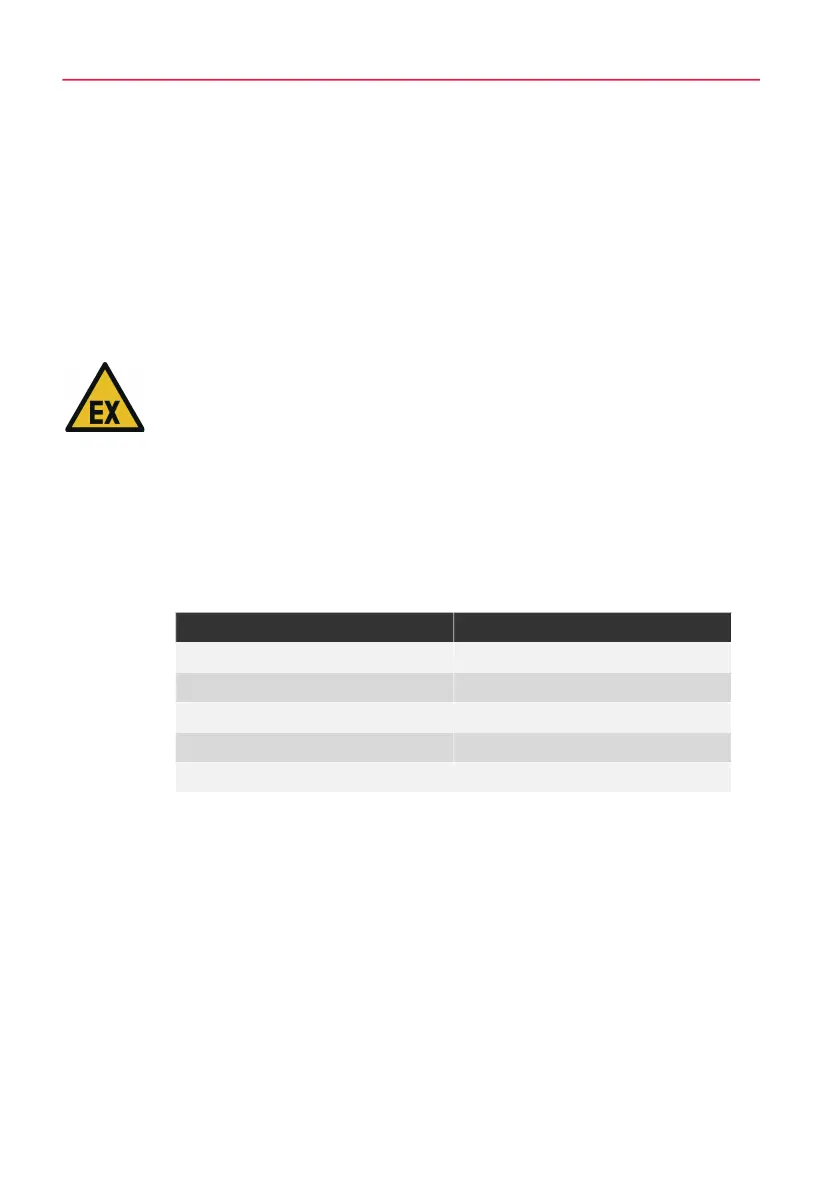

The space between the SFP connection and the leakage connections Z1 and, if ap-

plicable, Z3 is subject to a change in volume per stroke during operation. The

stroke volume of the leakage chamber is specified in the table below:

Tab. 10-3 Leakage chamber stroke volume

* For two-stage equipment, the stroke volume must be selected according to the

respective stage.

Type* Leakage chamber stroke volume

DLE 2-1 910 cm³

DLE 5-1 360 cm³

DLE 15-1 105 cm³

DLE 30-1 42 cm³

DLE 75-1 6 cm³

Loading...

Loading...