Use in explosion-prone zones

0000000141 - 002 - EN 46

Purging plan for single-stage, single-acting and two-stage, double-acting gas

boosters

1) Prior to commissioning the gas booster, connect nitrogen to the inlet pres-

sure port (A) and to the purge port (SFP).

2) Switch on the gas booster for approx. 1 minute (based on the volume to be

purged).

3) Switch off the gas booster after the purging process has been completed.

4) The inlet pressure line (A) may then be connected with the gas source. Con-

tinuously purge the purge port during the compression process.

5) After the compression process has been completed, purge the compression

chamber again as described in step 2.

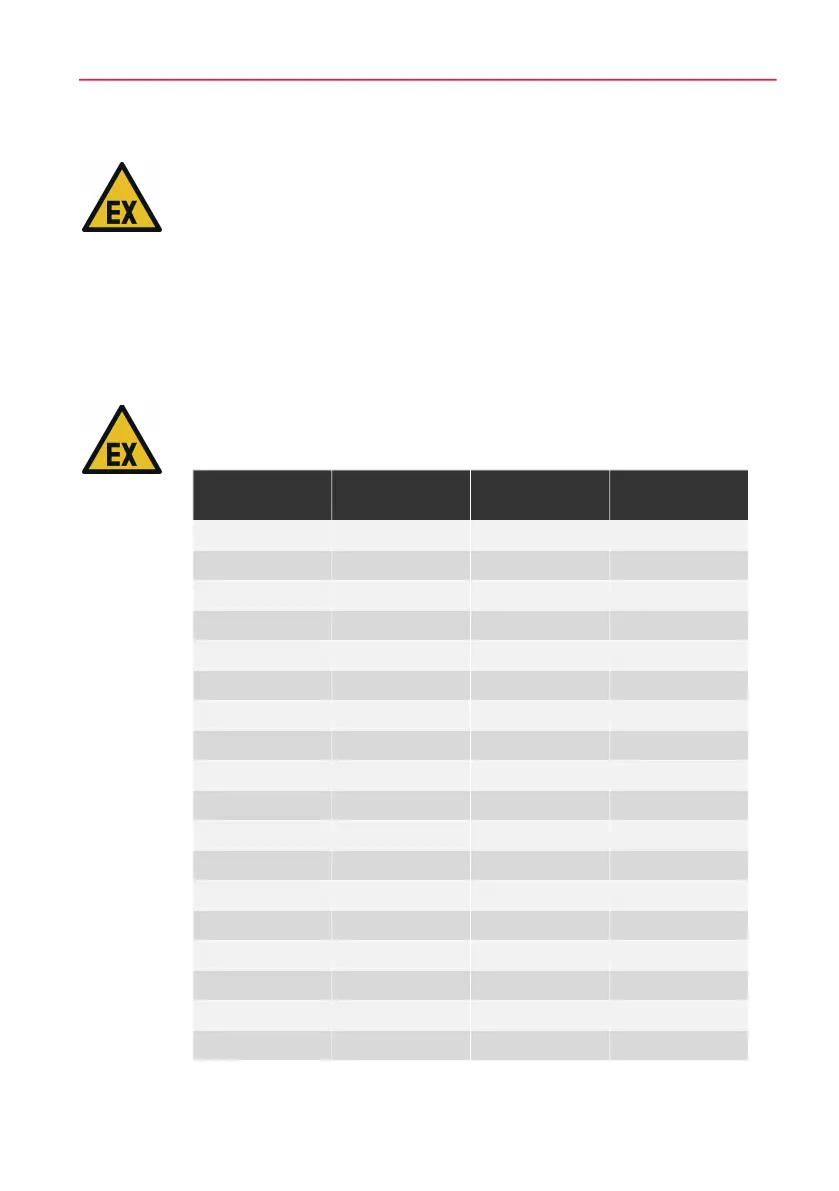

Volume flow for gas purging processes

To ensure an adequate purging performance, different volume flows must be en-

sured depending on the gas booster. The minimum required volume flow is

shown in the table below.

Tab. 10-2 Volume flows

Type Volume flow l

N

/

min

Type Volume flow l

N

/

min

DLE 2-1 190 DLE 15-1-2 30

DLE 5-1 90 DLE 30-1-2 20

DLE 15-1 40 DLE 75-1-2 10

DLE 30-1 20 DLE 2-2* 170

DLE 75-1 10 DLE 5-2* 80

DLE 2* 170 DLE 15-2* 30

DLE 5* 90 DLE 30-2* 20

DLE 15* 30 DLE 75-2* 10

DLE 30* 20 DLE 2-5-2 100

DLE 75* 10 DLE 5-15-2 60

DLE 2-5 110 DLE 5-30-2 70

DLE 5-15 60 DLE 15-30-2 20

DLE 5-30 70 DLE 15-75-2 20

DLE 15-30 20 DLE 30-75-2 10

DLE 15-75 30 DLE 30-75-3 10

DLE 30-75 10 8 DLE 1,65 -**

DLE 2-1-2 190 8 DLE 3 -**

DLE 5-1-2 90 8 DLE 6 -**

Loading...

Loading...