1-8

REFRIGERANT PIPING

Allowable Piping Length

If the pipe is too long, both the capacity and reliability of

the unit will drop. As the number of bends increases,

resistance to the fl ow of refrigerant system increases, thus

lowering cooling capacity. As a result, the compressor

may become defective. Always choose the shortest path

and follow the recommendations as tabulated below:

Model

Min. Allowable Length, m

Max. Allowable Length, m

Additional charge of refrigerant

Max. Allowable Elevation, m

Gas Pipe Size, mm/(in)

Liquid Pipe Size

, mm/(in)

10 15

3

15

20

10

9.52 (3/8")

6.35 (1/4")

*Be sure to add the proper amount of additional refrigerant.

Failure to do so may result in reduced performance.

Remark: The refrigerant pre-charged in the outdoor

unit is for piping length up to 7.5m.

Piping Works and Flaring technique

• Do not use contaminated or damaged copper tubing. If

any piping, evaporator or condenser had been exposed

or had been opened for 15 seconds or more, the system

must be vacuumed. Generally do not remove plastic,

rubber plugs and brass nuts from the valves, fi ttings,

tubing and coils until it is ready to connect suction or

liquid line into valves or fi ttings.

• If any brazing work is required, ensure that nitrogen

gas is passed through coil and joints while the brazing

work is being done. This will eliminate soot formation

on the inside wall of copper tubings.

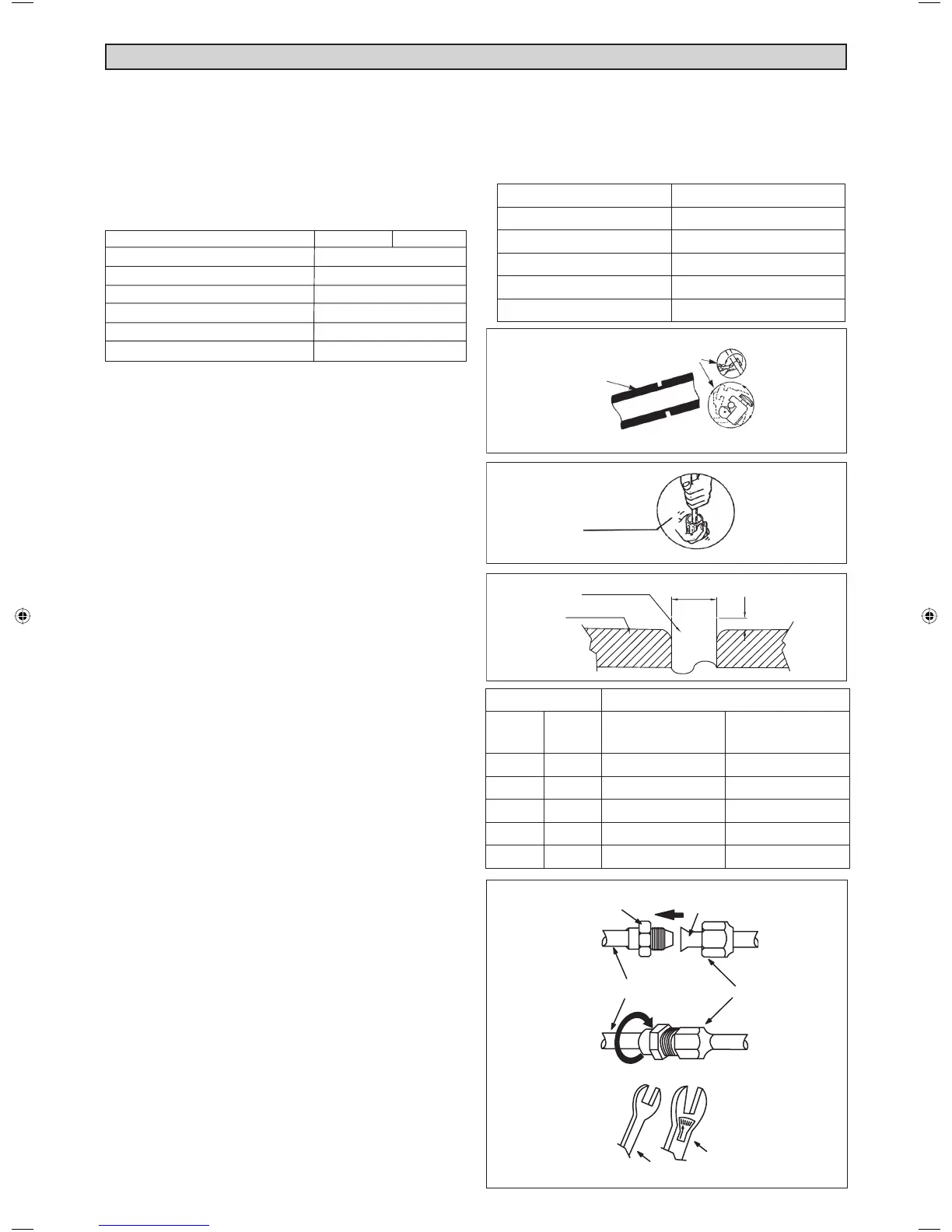

• Cut the pipe stages by stages, advancing the blade of

pipe cutter slowly. Extra force and a deep cut will cause

more distortion of pipe and therefore extra burr. See

Figure A.

• Remove burrs from cut edges of the pipes with remover.

See Figure B. Hold the pipe on top position and burr

removel at lower position to prevent metal chips from

entering the pipe. This will avoid unevenness on the

fl are faces which will cause gas leak.

• Insert the fl are nuts, mounted on the connection parts

of both the indoor unit and outdoor unit, into the copper

pipes.

• The exact length of pipe protruding from the top surface

of the swaging block is determined by the fl aring tool.

See Figure C.

• Fix the pipe fi rmly on the swaging block. Match the

centers of both the swaging block and the fl aring punch,

then tighten the fl aring punch fully.

• The refrigerant pipe connection are insulated by closed

cell polyurethane.

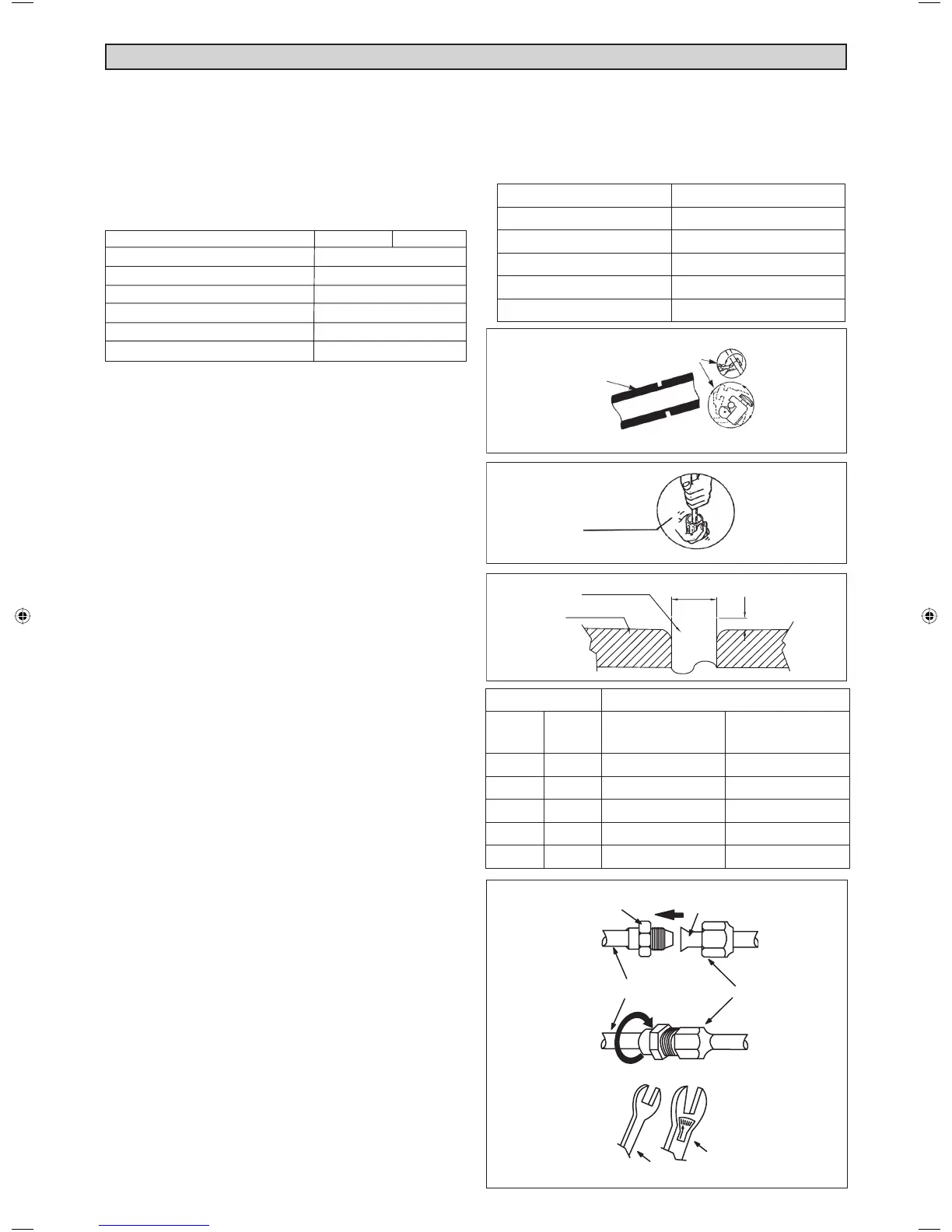

Piping Connection To The Units

• Align the center of the piping and tighten the fl are nut

suffi ciently with fi ngers. See Figure D.

• Finally, tighten the fl are nut with torque wrench until the

wrench clicks.

• When tightening the fl are nut with the torque wrench,

ensure that the tightening direction follows the arrow

indicated on the wrench.

• The refrigerant pipe connection are insulated by closed

cell polyurethane.

Pipe Size, mm (in) Torque, Nm / (ft-Ib)

6.35 (1/4") 18 (13.3)

9.52 (3/8") 42 (31.0)

12.70 (1/2") 55 (40.6)

15.88 (5/8") 65 (48.0)

19.05 (3/4") 78 (57.6)

Ø Tube, D A (mm)

Inch mm Imperial

(Wing-nut Type)

Rigid

(Clutch Type)

1/4" 6.35 1.3 0.7

3/8" 9.52 1.6 1.0

1/2" 12.70 1.9 1.3

5/8" 15.88 2.2 1.7

3/4" 19.05 2.5 2.0

Figure A

Figure B

Figure C

Figure D

Flared Tube

Flare Joint

Flare Nut

Indoor Piping

Torque Wrench

Spanar

Copper Tube

Swaging Block

1/4t

Cutting Copper Tube

Remove Burr

A

D

MacQuay IM-WMJ-1110(0).indd 8MacQuay IM-WMJ-1110(0).indd 8 1/12/2011 6:26:00 PM1/12/2011 6:26:00 PM

Loading...

Loading...