IM 474-3

15

Network Commissioning

NOTICE

This section discusses the commissioning of a MicroTech network. Only personnel trained in

MicroTech network commissioning procedures are allowed to commission a network. (This

section is for review and guidance.) Network commissioning training classes are held periodically

at McQuay International’s Minneapolis location. Contact the Controls and Network Systems group

for more information on network commissioning training classes and dates.

Unless special arrangements have been made, commissioning an Open Protocol network (i.e., the

McQuay equipment including only the OPM or its substitute and all MicroTech unit or auxiliary

controllers) is the responsibility of the McQuay sales representative, not the BAS company.

The purpose of network commissioning is to establish and verify communications between the OPM

(or its substitute) and its networked MicroTech unit or auxiliary controllers. (It is not to establish and

verify unit operation.) The network commissioning procedure is similar for all level-1 panels used in

an Open Protocol environment when two or more unit controllers are included in the network. This

commissioning section pertains to the OPM, but the procedures are similar for the RMS, RMC, CSC,

LLLB, and CPC panels. For additional commissioning requirements of these OPM substitutes, refer

to their installation manuals.

Network commissioning can be done independently of the unit commissioning procedures; however,

if it is done before the units are commissioned, care should be taken to assure that the units do not

start. Before any unit is allowed to operate, it must be commissioned in accordance with the

instructions in the MicroTech unit controller installation literature (see Table 1 on page 3) and the

model-specific unit installation literature.

Note:

This section does not discuss the commissioning procedures for a MicroTech 2000 network.

For information on that, see Bulletin No. IM 661, MicroTech Communications Gateway.

Required Tools

To commission the network, you need the following tools:

1.

Voltmeter

2.

Ohmmeter

3.

PC equipped with Open Protocol Monitor software

4.

Cable to connect the PC to a MicroTech controller

For more information on the PC and cable, see “PC Connection” on page 13.

About the Network Address

For network communications to occur, each controller in the network must have a unique network

address. The network address has two parts: L2 address and L3 address. Each part is a two-digit

hexadecimal number. For example, a unit at address “01.0F” has an L2 address of 01 and an L3

address of 0F (decimal 15). The first digit in each part is called the HI digit, and the second digit is

called the LO digit. Thus for the L3 address 0F, the HI digit is “0” and the LO digit is “F.” Table 6 is a

hexadecimal to decimal conversion guide.

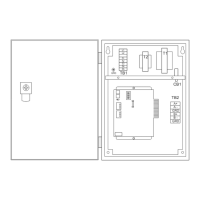

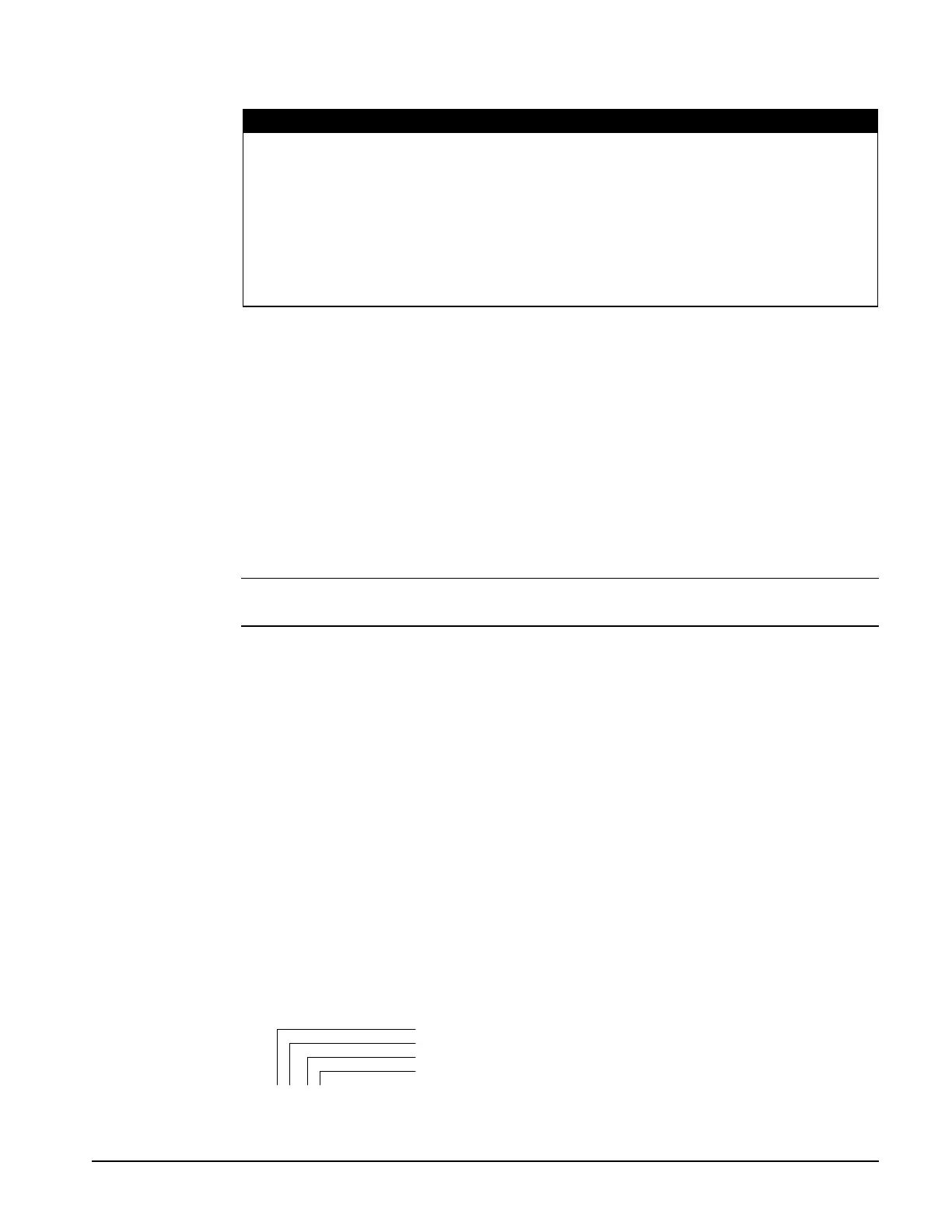

Figure 8. MicroTech Network Address

01.0F

L2 HI digit

L2 LO digit

L3 HI digit

L3 LO digit

Loading...

Loading...