Page 38 IM-738

Subcooling

When field charging the unit, the following must be followed

to properly charge the unit:

• All compressors on each circuit operating at full capacity.

• Allowable subcooling ranges are between 13°F to 20°F.

• Ambient temperature must be between 60°F and 105°F.

• Hot Gas Bypass NOT operating (only if unit is supplied with option)

• SpeedTrol motors operating at 100%

(only if unit is supplied with option)

If any one of the above items is not followed, subcooling read-

ings will not be accurate and the potential exists for over or

undercharging of the refrigerant circuit.

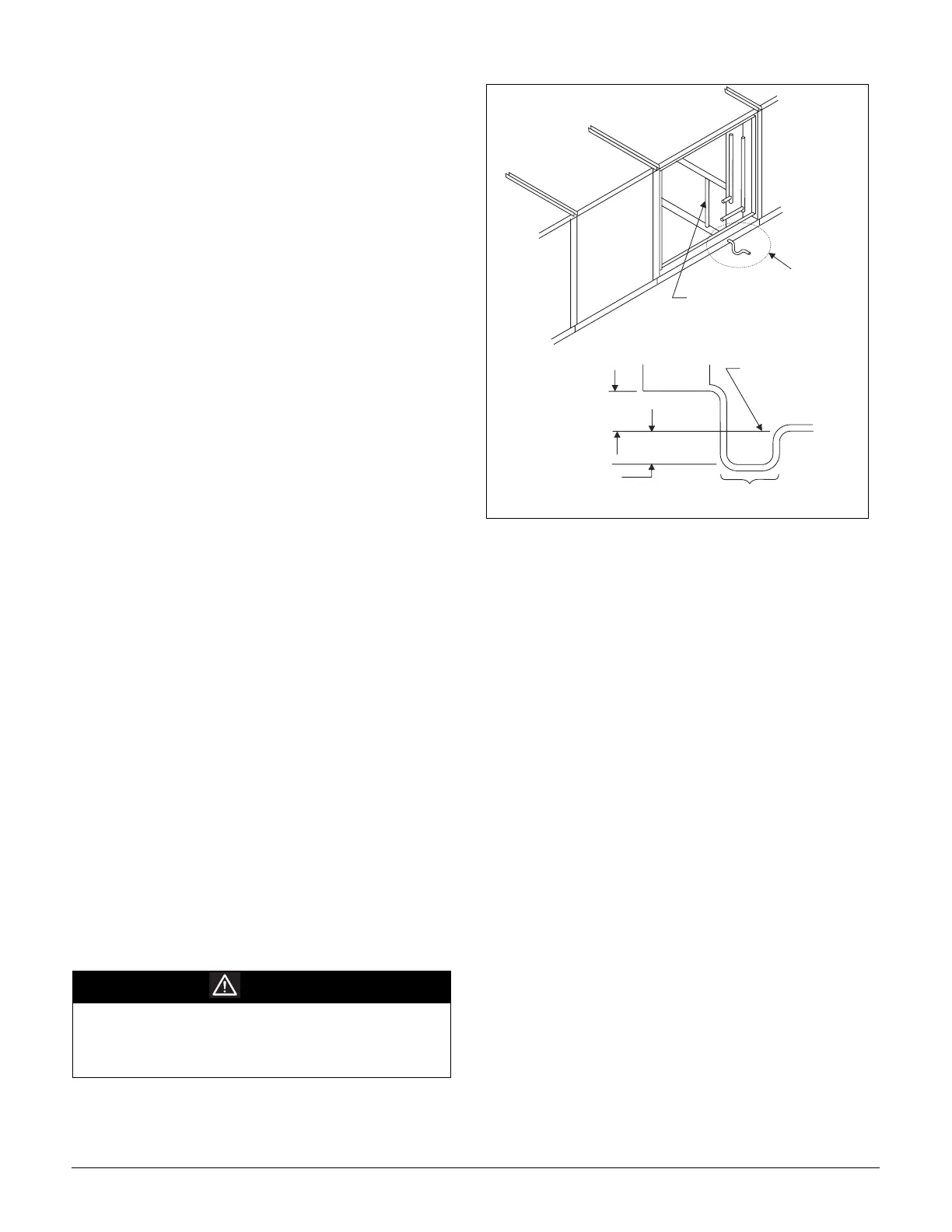

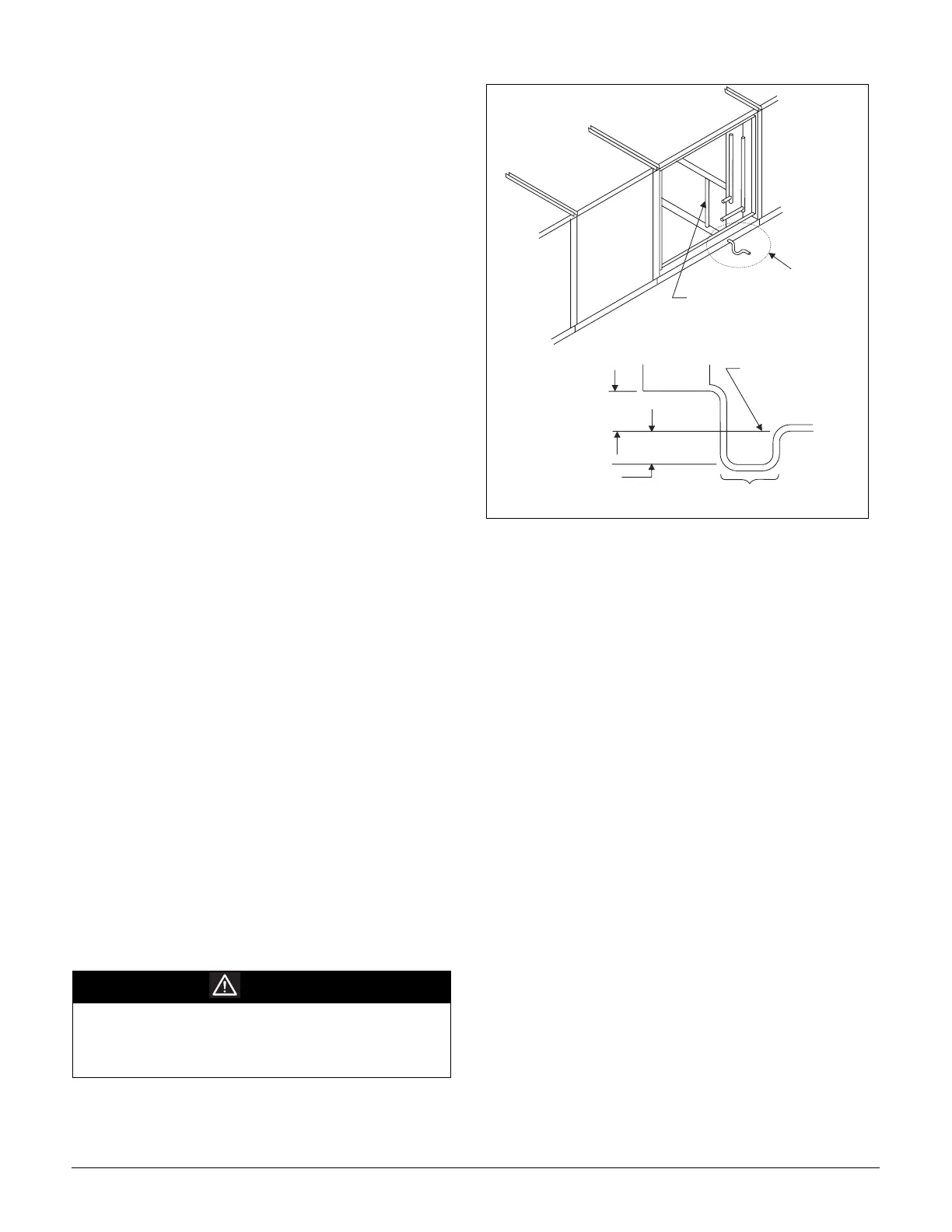

Condensate Drain Connection

The unit is provided with a 1.5" male NPT condensate drain

connection. Refer to certified drawings for the exact location.

The unit and drain pan must be level side to side and a P-trap

must be installed for proper drainage.

RPS units may have positive or negative pressure sections. It is

recommended that traps be used in both cases with care given

to negative pressure sections. In Figure 42, dimension "A"

should be a minimum of 8" (203 mm). As a conservative mea-

sure to prevent the cabinet static pressure from blowing or

drawing the water out of the trap and causing air leakage,

dimension A should be two times the maximum static pressure

encountered in the coil section in inches w.c.

Drainage of condensate directly onto the roof may be accept-

able; refer to local codes. It is recommended that a small drip

pad of either stone, mortar, wood or metal be provided to pro-

tect the roof against possible damage.

If condensate is to be piped into the building drainage system,

the drain line should be pitched away from the unit at a mini-

mum of 1/8" per foot. The drain line must penetrate the roof

external to the unit. Refer to local codes for additional require-

ments. Sealed drain lines require venting to provide proper

condensate flow.

Where the cooling coils have intermediate condensate pans on the

face of the evaporator coil, copper tubes near both ends of the coil

provide drainage to the main drain pan. Check that the copper

tubes are in place and open before the unit is put into operation.

Because drain pans in any air conditioning unit will have some

moisture in them, algae, etc. will grow. Periodic cleaning is

necessary to prevent this buildup from plugging the drain and

causing the drain pan to overflow. Also, the drain pans should

be kept clean to prevent the spread of disease. Cleaning should

be performed by qualified personnel.

Figure 42. Condensate drain connection

Unit Piping

Gas Piping

See the "Installation" section of the gas-fired furnace installa-

tion manual, Bulletin No. IM 684 or 685.

Fuel Oil Piping

See the "Installation" section of the forced draft oil-fired fur-

nace installation manual, Bulletin No. IM 198.

Hot Water Coil Piping

Hot water coils are provided without valves for field piping

or piped with three-way valves and actuator motors. Note: If

the unit is equipped with an iron valve, connecting to a cop-

per piping system will likely cause galvanic corrosion to

occur and the valve will not last. All coils have vents and

drains factory installed.

Hot water coils are not normally recommended for use with

entering air temperatures below 40°F (4°C). No control system

can guarantee a 100% safeguard against coil freeze-up. Glycol

solutions or brines are the only freeze-safe media for operation

of water coils at low entering air temperature conditions.

When no factory piping or valve is included, the coil connec-

tions are 1 5/8" ODM copper. With the factory piping and valve

package, field piping connections are the same NPT size as the

valve with female threading (see Figure 43 on page 39).

Refer to the certified drawings for the recommended piping

entrance locations. All piping penetrations must be sealed to

prevent air and water leakage.

Note: The valve actuator spring returns to a stem down

position upon power failure. This allows full flow

through the coil.

WARNING

Material that can grow in drain pans should be

cleaned on periodically. Material in uncleaned drain

pans may cause disease.

Cleaning should be performed by qualified personnel.

S t a t i c P r e s s u r e " P "

( i n . w . o . )

D r a i n P a n

4 " ( 1 0 2 m m )

M i n i m u m

" A "

8 " ( 2 0 3 m m )

M i n . o r 2 x " P "

M i n i m i z e T h i s

D i m e n s i o n

N o t e : D r a i n l i n e m u s t

n o t b e r u n h i g h e r

t h a n t h i s l e v e l

C o p p e r T u b e

( o n e e a c h e n d o f c o i l )

S e e V i e w " A "

Loading...

Loading...