Page 94 IM-738

4. Tag the valves as a warning for the technician who will be

restarting the units

5. Note: steps I. to 4. are not necessary if the unit had not yet

been started.

Gas Furnace

If the unit is equipped with a gas furnace, close the gas shutoff

valve and open furnace control switch S3.

Control Compartment

1. McQuay International recommends that the electronic con-

trol equipment in the unit be stored in a 5% to 95% RH

(non-condensing) environment.

2. It may be necessary to put a heat source (light bulb) in the

main control panel to prevent the accumulation of atmo-

spheric condensate within the panel.

3. The location and wattage of the heat source will be depen-

dent on local environmental conditions.

4. Check the control compartment every two weeks to pro-

vide that the heat source is functional and is adequate for

current conditions.

Restart

After extended storage, a very complete start up must be per-

formed. Inevitable accumulations of dirt, insect nests, etc. can

contribute to problems if not cleaned out thoroughly prior to

start up. In addition, thermal cycling will have tended to loosen

mechanical and electrical connections. Following the start up

procedure will help discover these and other issues that may

have developed during the storage interval.

Gas Furnace

For information on maintenance of the gas furnace, refer to

Bulletin No. IM 684 or 685.

Bearing Lubrication

Motor Bearings

Supply and return fans - Supply and return fan motors should

have grease added after every 2,000 hours of operation. Use

one of the greases shown in Table 22 on page 94. Using the

following procedure, relubricate the bearings while the motor

is warm, but not running.

1. Remove and clean upper and lower grease plugs.

2. Insert a grease fitting into the upper hole and add a small

amount of clean grease with a low pressure gun.

3. Run the motor for five minutes before replacing the plugs.

Note: Specific greasing instructions may be found on a tag

attached to the motor. If special lubrication instruc-

tions are on the motor, they will supersede all other

instructions.

Condenser fan - Condenser fan motors are permanently lubri-

cated and require no periodic lubrication.

Fan Shaft Bearings

Fan shaft bearings should be relubricated periodically. Re-

lubricate according to the schedule shown in Table 23. If the

bearings are exposed to wet conditions, wide temperature

variations, or other severe atmospheric conditions, relubri-

cate more frequently. Use one of the greases shown in

Table 22.

While the bearing is at normal operating temperatures, rotate

the fan by hand and add only enough grease to purge the

seals. The seals will bleed slightly when this has occurred.

Do not overlubricate.

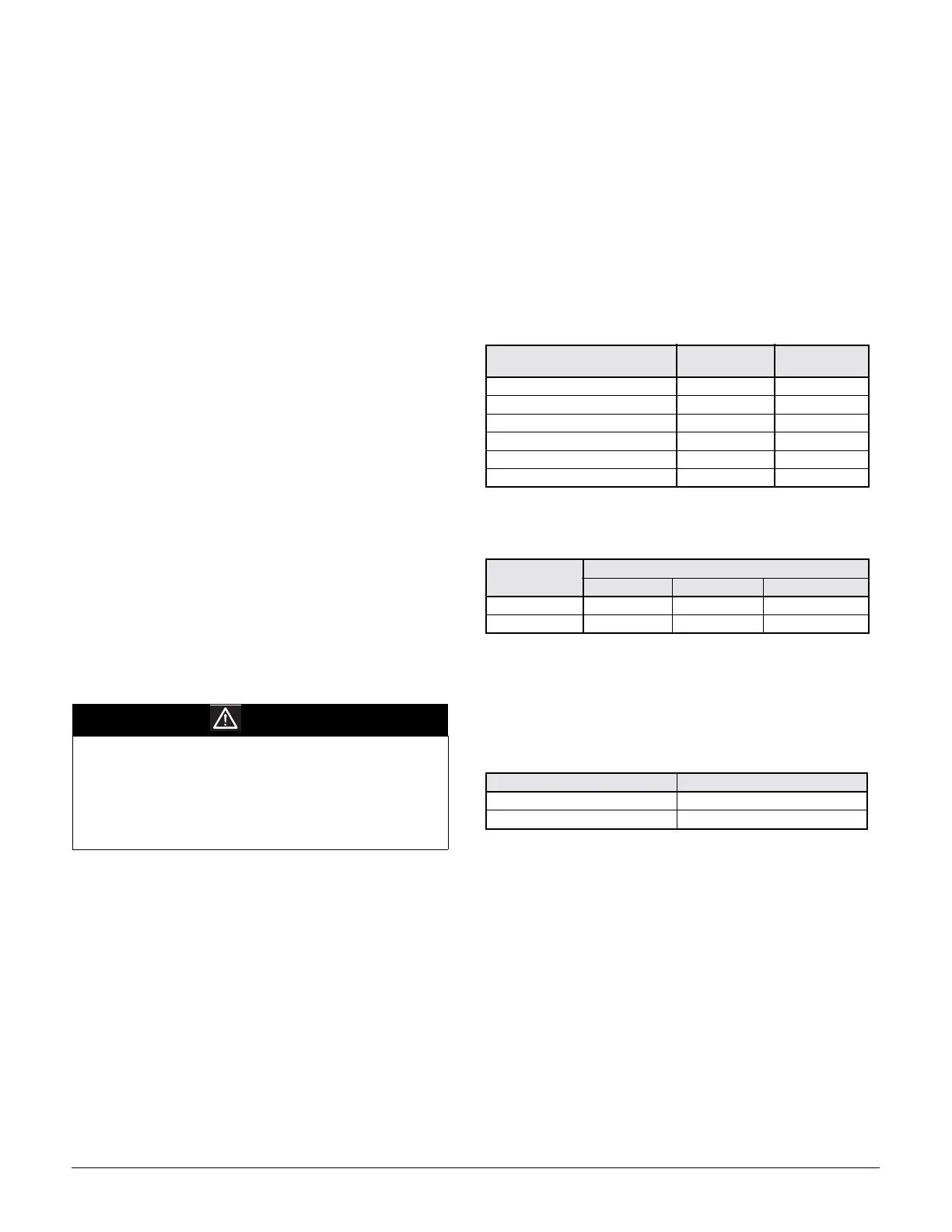

Table 22: Recommended greases

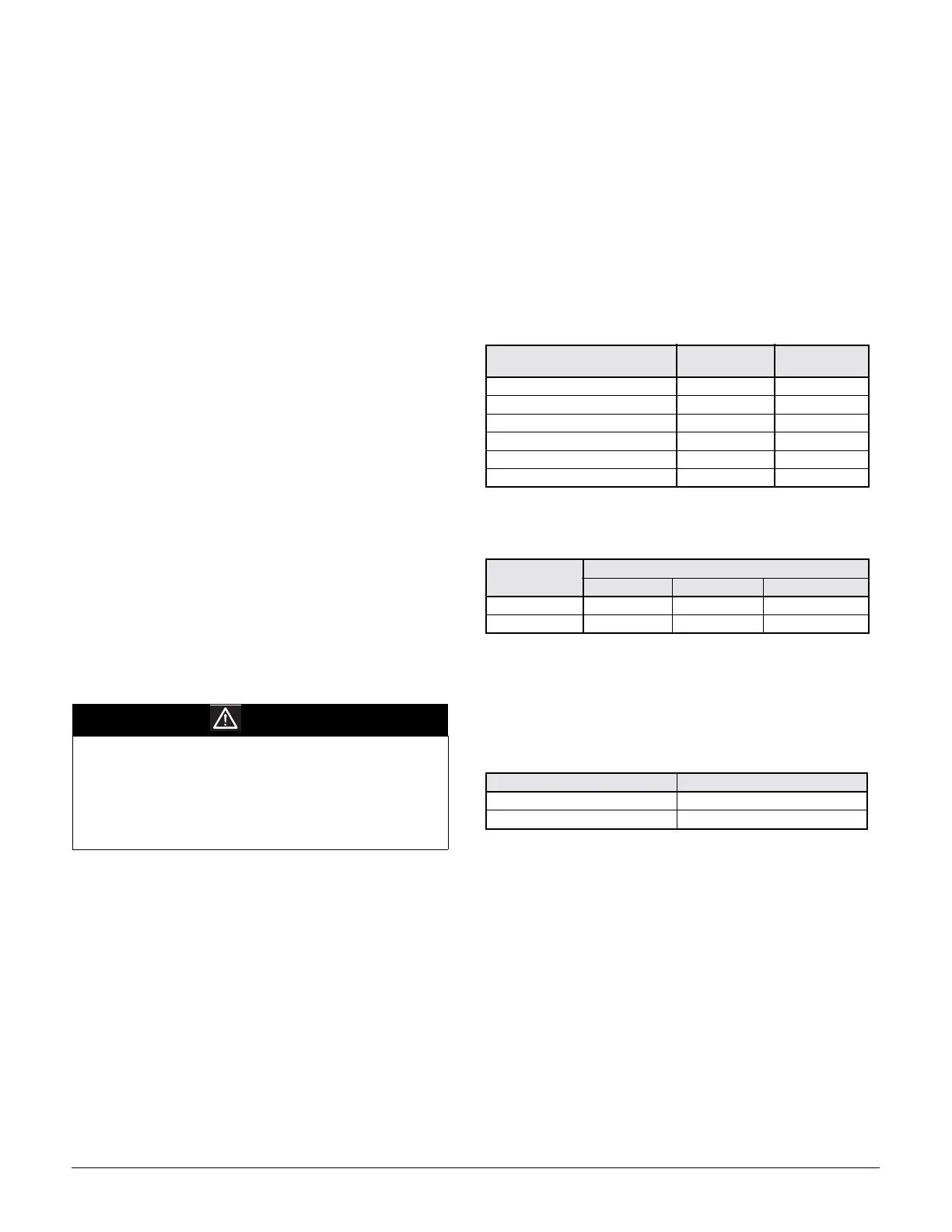

Table 23: Recommended Fan Shaft Bearing

Lubrication Intervals

Vibration Levels

Each unit as shipped has been trim-balanced to operate

smoothly. To provide satisfactory operation after shipping

and installation, use the accepted industry guidelines for field

balancing fans. See Table 24.

Table 24: Vibration Levels

Note: Excessive vibration from any cause contributes to premature fan and

motor bearing failure. Overall vibration levels should be monitored every six

months of operation. An increase in levels is an indication of potential trouble.

Vibration Causes

1. Wheel imbalance.

a. Dirt or debris on wheel blades.

b. Loose setscrews in wheel hub or bearing-to-shaft.

c. Wheel distorted from overspeed.

2. Bent shaft.

3. Drive faulty.

a. Variable pitch sheaves - Axial and radial runout of

flanges; uneven groove spacing; out of balance. Also

similar faults in driven sheave.

CAUTION

Bearing overheating potential. Can cause damage

to the equipment.

Do not overlubricate bearings.

Use only a high grade mineral grease with a 200°F safe

operating temperature. Refer to Table 22 on page 94 for

specific recommended lubricants.

MANUFACTURER PRODUCT

NAME

TEMP.

RANGE (°F)

Texaco Lubricants Co. Premium RB -30 to 300

Keystone Ind. Lubricants 84EP-2 -40 to 200

Mobil Oil Corporation Mobilith AW2 -40 to 325

Chevron U.S.A. Inc. SRI-2 -20 to 325

Exxon Company. U.S.A. Ronex MP -40 to 300

Shell Oil Company Alvania No. 2 -20 to 240

OPERATING

DUTY

BEARING AMBIENT TEMPERATURE

TO 130°F TO 150°F OVER 150°F

Continuous 6 months 4 months 2 months

12 Hrs./Day 12 months 12 months 6 months

FAN SPEED (RPM) VIBRATION

800 or less 5 mils maximum displacement

801 or greater 0.20 in/sec. maximum velocity

Loading...

Loading...