Page 66 IM-738

Variable Inlet Vanes

Variable inlet vanes are installed on the supply and return fans

of VAV units. They are also installed on the return fans of con-

stant volume units that have direct building static pressure con-

trol capability.

The inlet vane assemblies consist of airfoil type inlet fun-

nels with integral sets of lever-actuated radial vanes. Sup-

ply fans have one assembly on each side of the fan. Return

fans have one assembly on the inlet side of the fan only.

When they open, the inlet vanes direct air in the direction

of wheel rotation.

The vanes are able to rotate 90 degrees from full closed to full

open. A stop limits the amount of travel open and must not be

changed. Driving the vanes past this stop will cause the vane

hub cam linkage to disengage. The vanes will turn indepen-

dently of each other, and the hub assembly will have to be

overhauled. The moving parts of the vanes are permanently

lubricated. All threaded fasteners must be periodically checked

for tightness

All fans with inlet vanes are provided without motor actuators

for field control installation, or may be shipped from the fac-

tory with complete linkage and actuator assemblies. Field

installed linkages and actuators would be connected as shown

in Figure 69 on page 67 thru Figure 75 on page 70 .

Minimum Vane Position

Operation with the inlet vanes closed completely may result in

fan pulsation and excessive vibration. In units equipped with

MicroTech II controls, the vanes are automatically opened

approximately 5 degrees by the control system prior to fan

start-up. Field installed linkages and actuators should be pre-

set to close to no less than 5 degrees open.

Supply Fan Vane Adjustment

Figure 69

& Figure 70 on page 67, Figure 71 on page 68 and

Figure 74 on page 69 thru Figure 75 on page 70 show the sup-

ply fan vane linkage assembly. Both sets of vanes on the supply

fan must operate in unison. Adjustments to the motor rod end

and locknut as well as to the floating link ends (Point A) can be

made to provide uniformity between the linkage assemblies.

The vane actuators must have 180-degree rotation. Do not

make linkage adjustments to compensate for improper actuator

rotation, but correct the actuator rotation adjustment. Refer

to“Actuator Rotation Adjustment” on this page.

On units with vane controls on both the supply and return fan,

it is important that both actuators have exactly 180-degree

rotation to provide proper "tracking" of the two actuators.

Inlet vanes must not be adjusted to close tight during fan oper-

ation. A minimum of 5° open is recommended to avoid fan

pulsation. Units with factory installed MicroTech II controls

will automatically open vanes 5 degrees prior to start-up.

As the actuator moves from 0° to 180°, the vanes should move

from 0° (closed) to 90° (full open). This can be adjusted by

changing the linkage rod length by loosening the nut and slid-

ing the rod at Point A or Point B and retightening the nut.

Return Fan Vane Adjustment

Refer to Figure 71 on page 68 for 30" wheels and Figure 70

on page 67 thru Figure 73 on page 69 for 40" wheels. The

vane actuator must have 180-degree rotation. Do not make

linkage adjustments to compensate for improper rotation, but

correct the actuator rotation adjustment. (Refer to the "Actua-

tor Rotation Adjustment" section following.)

As the actuator crankarm rotates from 0 degrees to 180

degrees, the vanes should move from 0 degree (closed) to 90

degrees (full open). This can be adjusted by changing the

linkage rod length by loosening the nut and sliding the rod at

Point A or Point B and retightening the nut.

Inlet vanes must not be adjusted to close tight during fan

operation. A minimum of 5º open is recommended to avoid

fan pulsation. Units with factory installed MicroTech II con-

trols will automatically open vanes 5º prior to startup.

Actuator Rotation Adjustment

The counterclockwise (as viewed from shaft end of actuator)

limit switch is adjustable on the Siebe actuator. The clock-

wise limit is not adjustable. The counterclockwise limit set-

ting can be changed in the field by inserting a screwdriver

through the opening in the top plate directly ahead of the ter-

minal block on the shaft side and engaging the screwdriver

blade with the edge of the notched cam nearest the front of

the actuator. Turning the cam clockwise (as viewed from the

shaft) increases the amount of actuator rotation. Each click of

the cam represents about 3 degrees of change in actuator

rotation. The actuator should be set for 180-degree rotation.

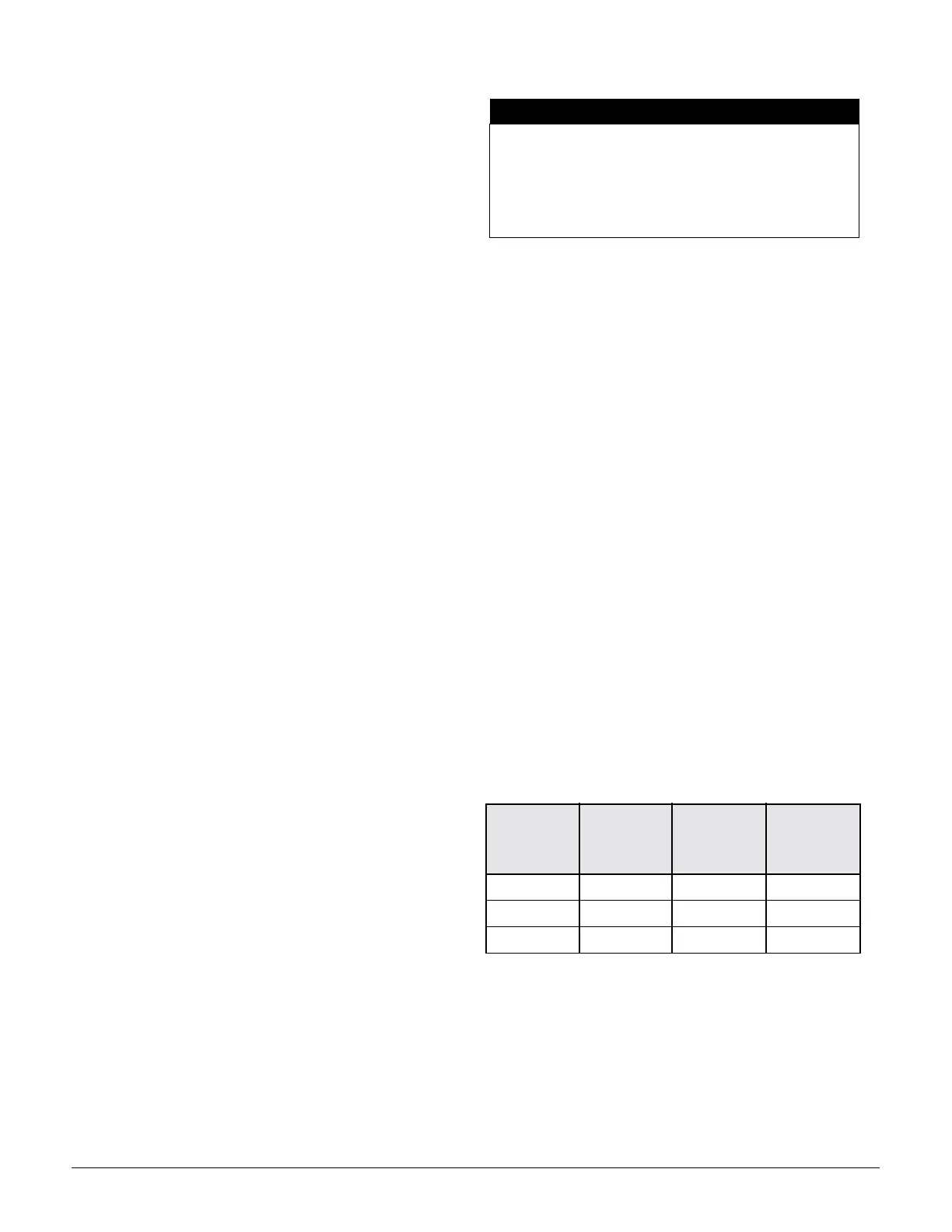

Table 19: Applicable Actuator Linkage Configurations

NOTICE

Inlet vanes must not be adjusted to close tight

during fan operation.

A minimum operating position of 5 degrees open is

recommended to avoid pulsation.

Units with factory installed MicroTech II controls will

automatically open vanes 5 degrees prior to start-up.

Supply Fan

Wheel Size

(In Inches)

Z

(Refer to

Figure 71 on

page 68)

Motor

HP

Figure 71 on

page 68

Reference

View

27 38.1 (968mm) 5—40 2

30 42.3 (1074mm) 5—40 2

33 46.4 (1179mm) 5—40 2

Loading...

Loading...