Page 96 IM-738

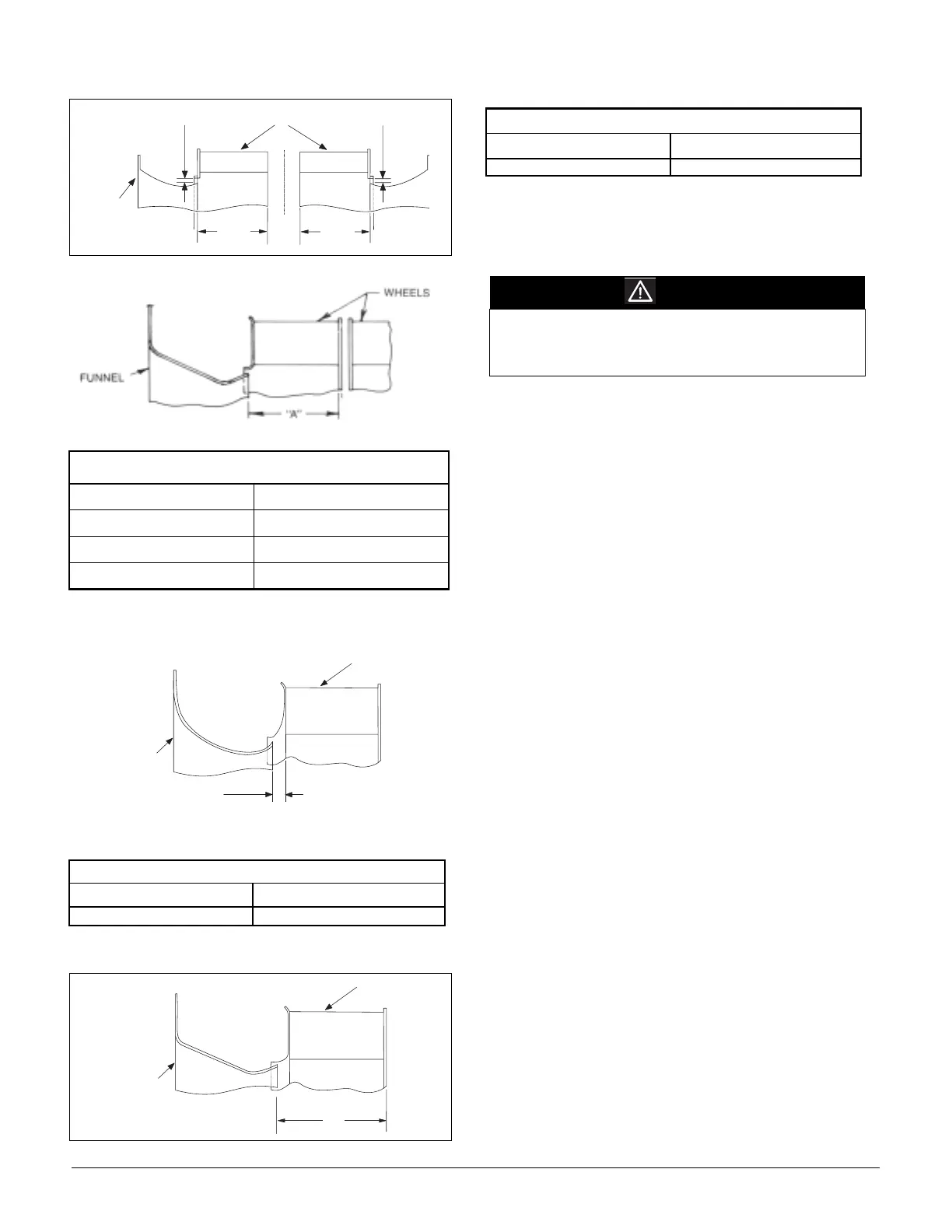

Figure 97. 24" Backward Curved Wheel-to-Funnel

(036C, 040C)

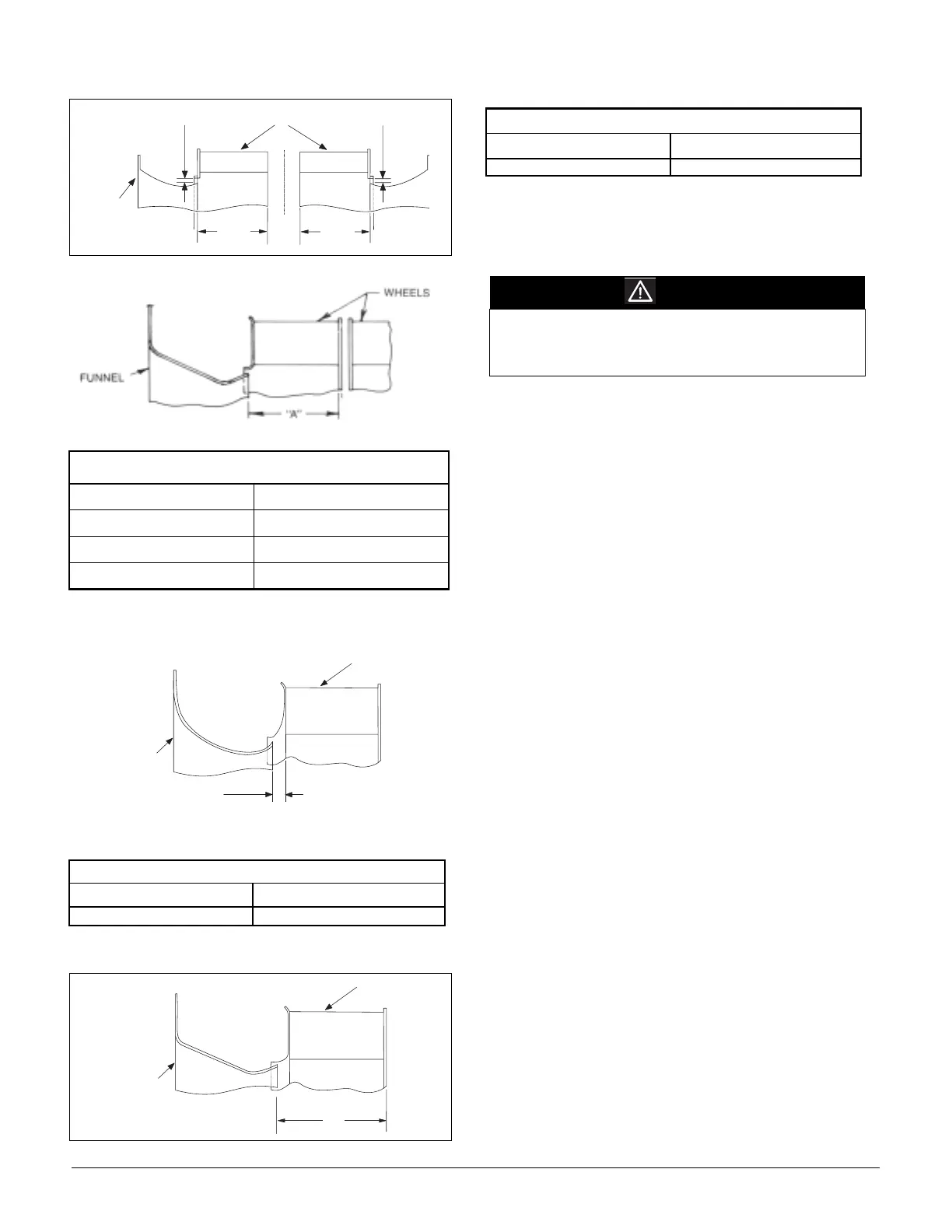

Figure 98. Airfoil Wheel-to-Funnel Alignment

Table 26: Airfoil Wheel-to-Funnel Tolerances

Figure 99. 40" Airfoil Wheel-to-Funnel Alignment

(RDT 045 -075)

Table 27: 40"Airfoil Wheel-to-Funnel Tolerances

(RDT 045 -075)

Figure 100. 44" Airfoil Wheel-to-Funnel Alignment

Table 28: 44" Airfoil Wheel-to-Funnel Tolerances

(RDT 045 -075)

Refrigerant Charge

The unit nameplate references proper charge for each refriger-

ant circuit in case a full charge must be added to the unit.

Replacing Failed Refrigerant Sensors

or Switches

The McQuay Rooftop Unit includes the following refrigerant

sensors or switches.

1. Low refrigerant sensing, operating switch

2. SpeedTrol refrigerant sensing, operating sensor [see

“SpeedTrol (NA Unit Sizes 015C - 030C)” on page 64]

3. High refrigerant pressure, safety switch

The low pressure and Speedtrol sensors/ switches sense refrig-

erant pressure through schrader fittings that contain cores. The

cores are stop valves that will not allow refrigerant to flow

through the schrader unless the device is in place. Therefore

the low pressure and Speedtrol sensors/switches can be

replaced without reclaiming the refrigerant.

The schrader that serves the high pressure switch does not con-

tain a core, in order to maximize the functionality of the safety.

Therefore it cannot be replaced unless the refrigerant has

already been reclaimed.

Winterizing Water Coils

Coil freeze-up can be caused by such things as air stratification

and failure of outdoor dampers and/or preheat coils. Routine

draining of water cooling coils for winter shutdown cannot be

depended upon as insurance against freeze-up. Severe coil dam-

age may result. It is recommended that all coils be drained as

thoroughly as possible and then treated in the following manner.

Fill each coil independently with an antifreeze solution using a

small circulating pump and again thoroughly drain.

Check freezing point of antifreeze before proceeding to next

coil. Due to a small amount of water always remaining in each

coil, there will be a diluting effect. The small amount of anti-

freeze solution remaining in the coil must always be concen-

trated enough to prevent freeze-up.

Note: Carefully read instructions for mixing antifreeze

solution used. Some products will have a higher

freezing point in their natural state than when mixed

with water.

Wheel-to-Funnel Relationship (In Inches)

Wheel Diameter Inches) “A” +0.3/ —0.0

27 9.90 (246mm)

30 10.60 (269mm)

33 11.70 (297mm)

WHEEL-TO-FUNNEL RELATIONSHIP

WHEEL DIA. (IN.) “A” (IN INCHES)

40

62

W h e e l

. 1 8 "

F u n n e l

9 . 3 1 "

9 . 3 1 "

C

L

F a n

. 1 8 "

W h e e l

F u n n e l

A

W h e e l

F u n n e l

A

WHEEL-TO-FUNNEL RELATIONSHIP

WHEEL DIA. (IN.)

“A” (IN INCHES)

44 16.21

WARNING

Potential severe loss of charge may occur if the high

refrigerant pressure switch is replaced before reclaiming

the refrigerant.

Replace switch after reclaiming refrigerant.

Loading...

Loading...