IM-738 Page 75

With the unit running, add grease very slowly with a manual

grease gun until a slight bead of grease forms at the seal. Be

careful not to unseat the seal by over lubricating or using

excessive pressure. Bearings without grease fittings are lubri-

cated for life.

Fasteners and Setscrews

Any fan vibration has a tendency to loosen mechanical fas-

teners. A periodic inspection should include checking all fas-

teners and set screws for tightness. Particular attention should

be paid to setscrews attaching the propeller to the shaft and

the shaft to the bearings. Loose bearing set screws will lead

to premature failure of the fan shaft.

Lubrication

Refer to “Bearings” on page 74 for bearing lubrication.

Many fractional horsepower motors installed on the smaller

fans are lubricated for life and require no further attention.

Motors equipped with oil holes should be oiled in accordance

with the manufacturer's instructions printed on the motor.

Use a high grade SAE 20 machine oil and use caution not to

over lubricate.

Motors supplied with grease fittings should be greased accord-

ing to directions printed on the motor.

Removal of Dust/Dirt

Dirt clogs cooling openings on the motor housing, contami-

nates bearing lubricant and collects on propeller blades caus-

ing severe imbalance if left unchecked. The exterior surface

of the motor, fan panel and entire propeller should be thor-

oughly cleaned periodically. Use caution and do not allow

water or solvents to enter the motor or bearings. Under no

circumstances should motors or bearings be sprayed with

steam or water.

Table 20: Propeller Exhaust Fan Troubleshooting

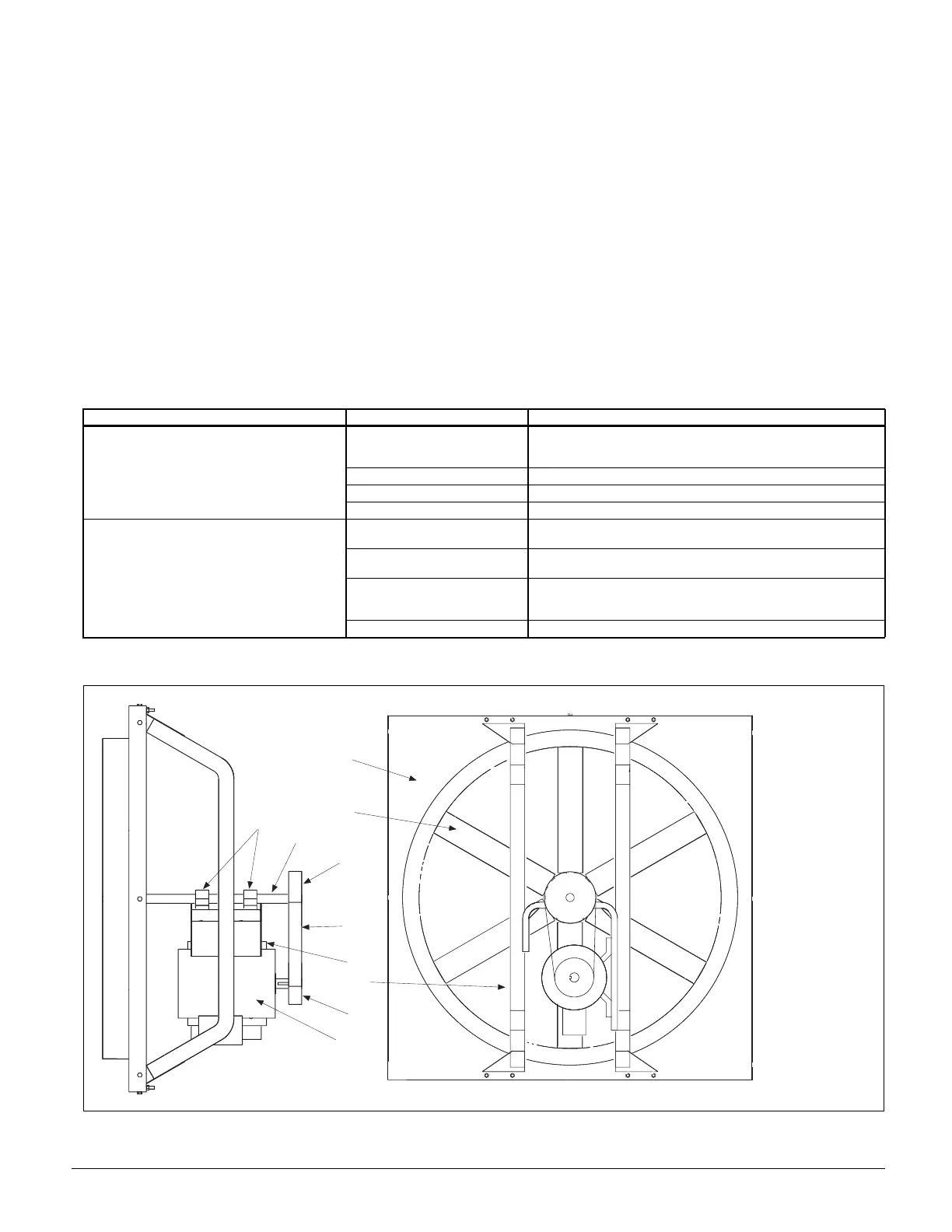

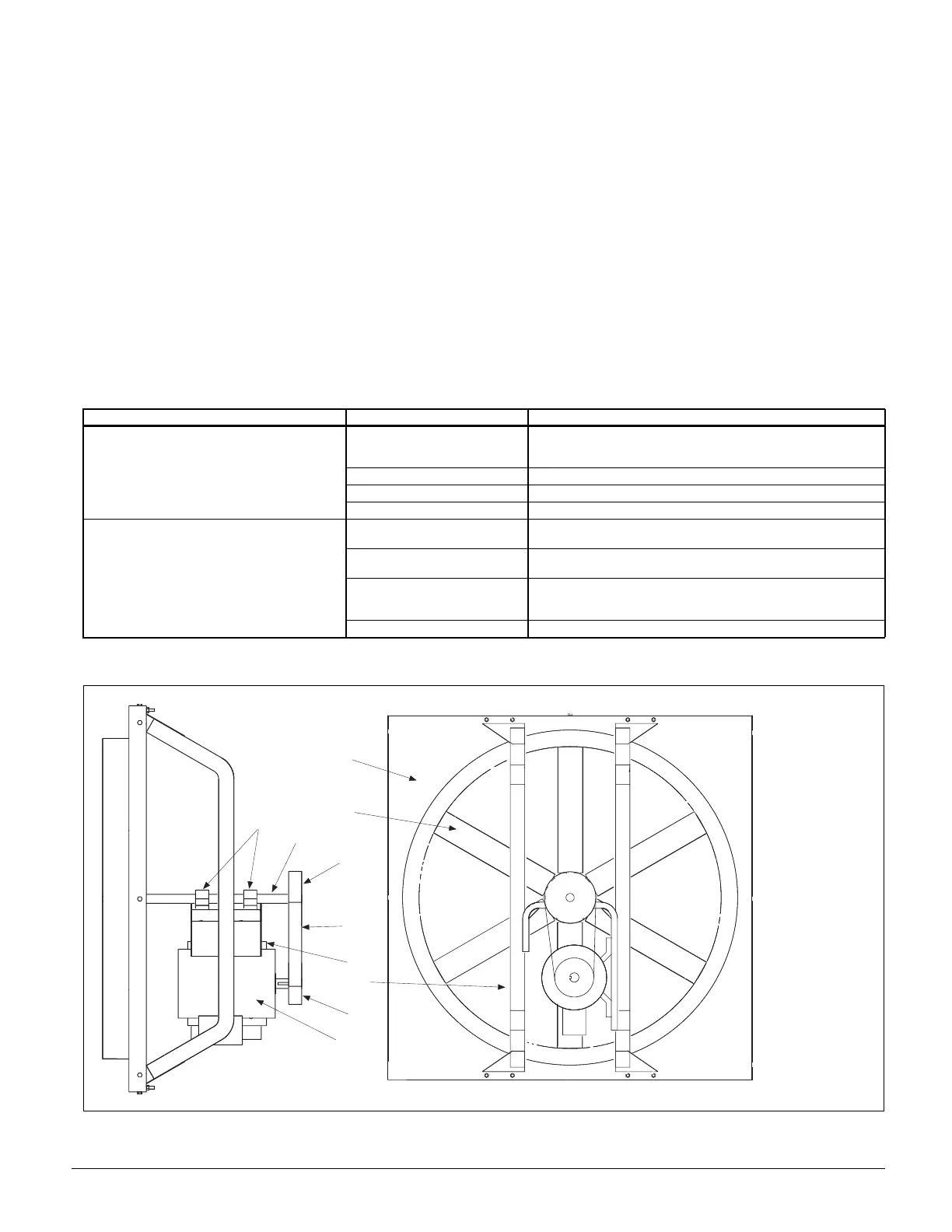

Figure 84. Propeller Exhaust Replacement Parts List

Problem Cause Corrective Action

Reduced Airflow

System resistance is too high.

Check backdraft dampers for proper operation. Remove

obstructions in ductwork. Clean dirty filters. Check for adequate

supply for air exhaust fans or exhaust air for supply fans.

Unit running backwards. See “Prestarting Checks” on page 73

Fan speed too low. Increase fan speed

Excessive dirt on propeller. Clean propeller

Excessive Noise

Bearings

Tighten bearing collars and setscrews. Lubricate bearings.

Replace defective bearings.

V-Belt drive

Tighten pulleys on motor shaft and fan shaft. Adjust belt tension.

Align pulleys. Replace worn belts or pulleys.

Excessive vibration

Clean dirt build-up from propeller. Check all setscrews and

fasteners for tightness. Check for worn bearing. Correct propeller

imbalance. Check for loose dampers, guards or ductwork.

Defective motor Replace motor.

9

8

7

1 0

6

5

4

1

2

3

1 . F a n P a n e l

2 . P r o p e l l e r

3 . D r i v e F r a m e

C h a n n e l ( 2 )

4 . M o t o r P l a t e

5 . M o t o r

6 . M o t o r P u l l e y

7 . S h a f t P u l l e y

8 . F a n S h a f t

9 . B e a r i n g s

1 0 . B e l t

1 1 . B e a r i n g P l a t e

Loading...

Loading...