199

Chapter 8 Maintenance

The influence of the ambient temperature, humidity, dust and vibration as well as the aging devices in the

drive may cause the drive faults. Thus, it is necessary to carry out daily and periodical maintenance.

8.1 Daily maintenance

Note

Before inspection and maintenance, please confirm the following items first. Otherwise, electric shock may

occur.

1

.The power supply of the drive has been cut off.

2

.Ensure that the charging LED lamp is off .

3

.The voltage between terminals (+DC )and terminals (-DC )measured by DC high-voltmeter should be below

36V.

The drive should be working in the environments stipulated in Section 2.1. In addition, there may be some

unexpected situations during the operation, so users should carry out daily maintenance according to the

instructions in the following table. The effective ways to prolong the service life of the drive is to maintain a

good operating environment, record daily operating data and discover the cause of abnormity as early as

possible.

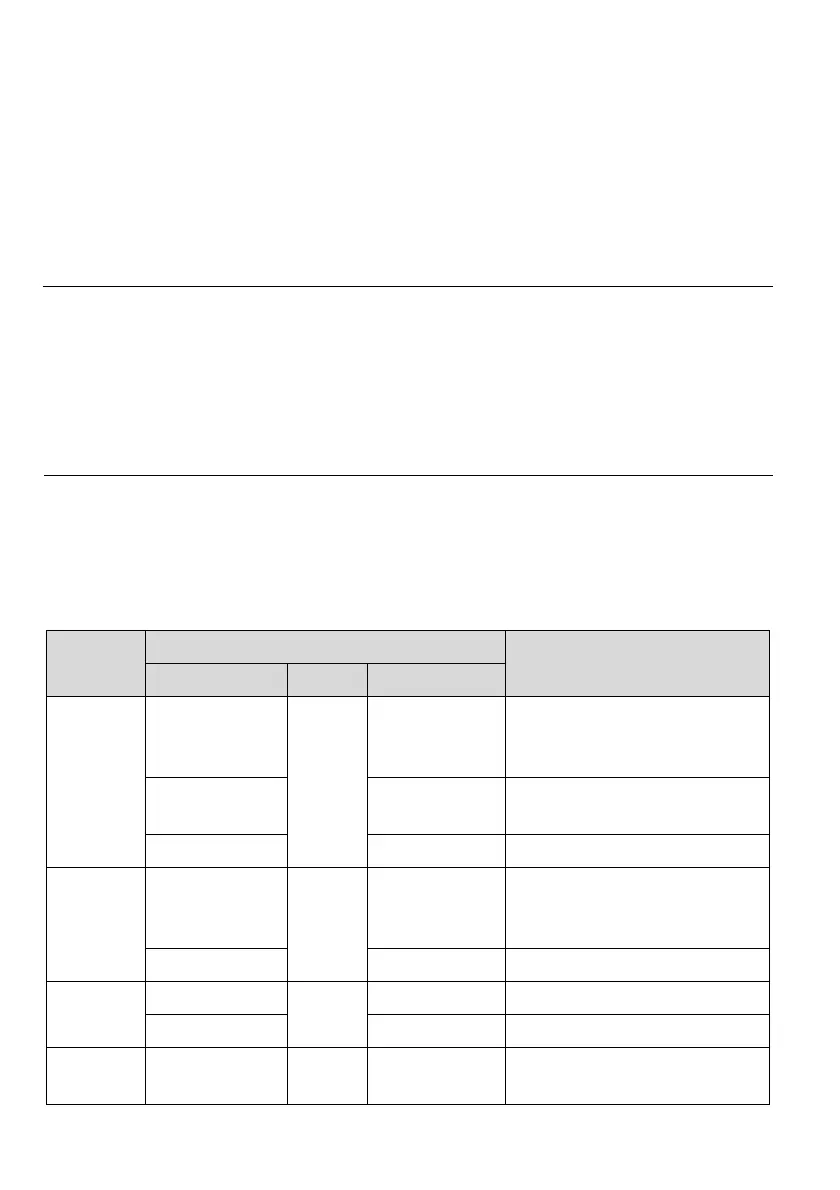

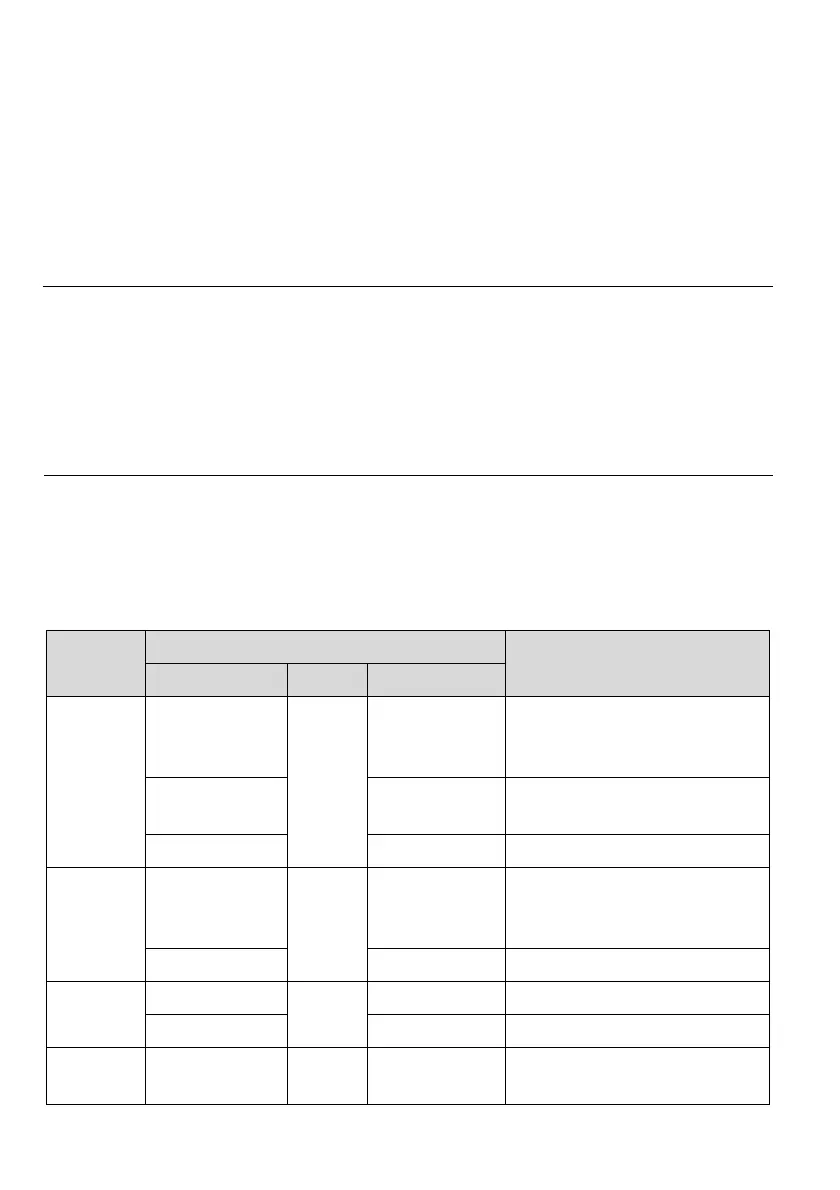

Table 8-1 Instructions for daily inspection

Inspection

items

Inspection essentials

Judgment standard

Inspection contents Cycle Inspection means

Operating

environment

1. Temperature and

humidity

Anytime

1. Temperature

meter and

hygrometer

1.-10℃~+40℃, derating is required at

40℃~50℃

2. Dust, water and

drop leak

2.Visual detection 2. No signs of drop of water and drop leak

3. Odor 3. Smell 3. No strange smell

Drive

1. Vibration and heat

generation

Anytime

1. Touch

1. The vibration is normal and stable. The

temperature of the enclosure and the

operating of the fan is normal.

2. Noise 2. Hear 2. No abnormal sound

Motor

1. Heat generation

Anytime

1. Touch by hand 1. Generating heat without any exception

2. Noise 2. Hear 2. Low and regular noise

Running

status

1. Output current Anytime 1. Current meter

1. Within the rated range and three-phase

equilibrium

Loading...

Loading...