Technical Bulletin—TC-9100 Universal Controller 31

The parameters that are dynamically generated by programmable

modules configured to use controller algorithms are listed below:

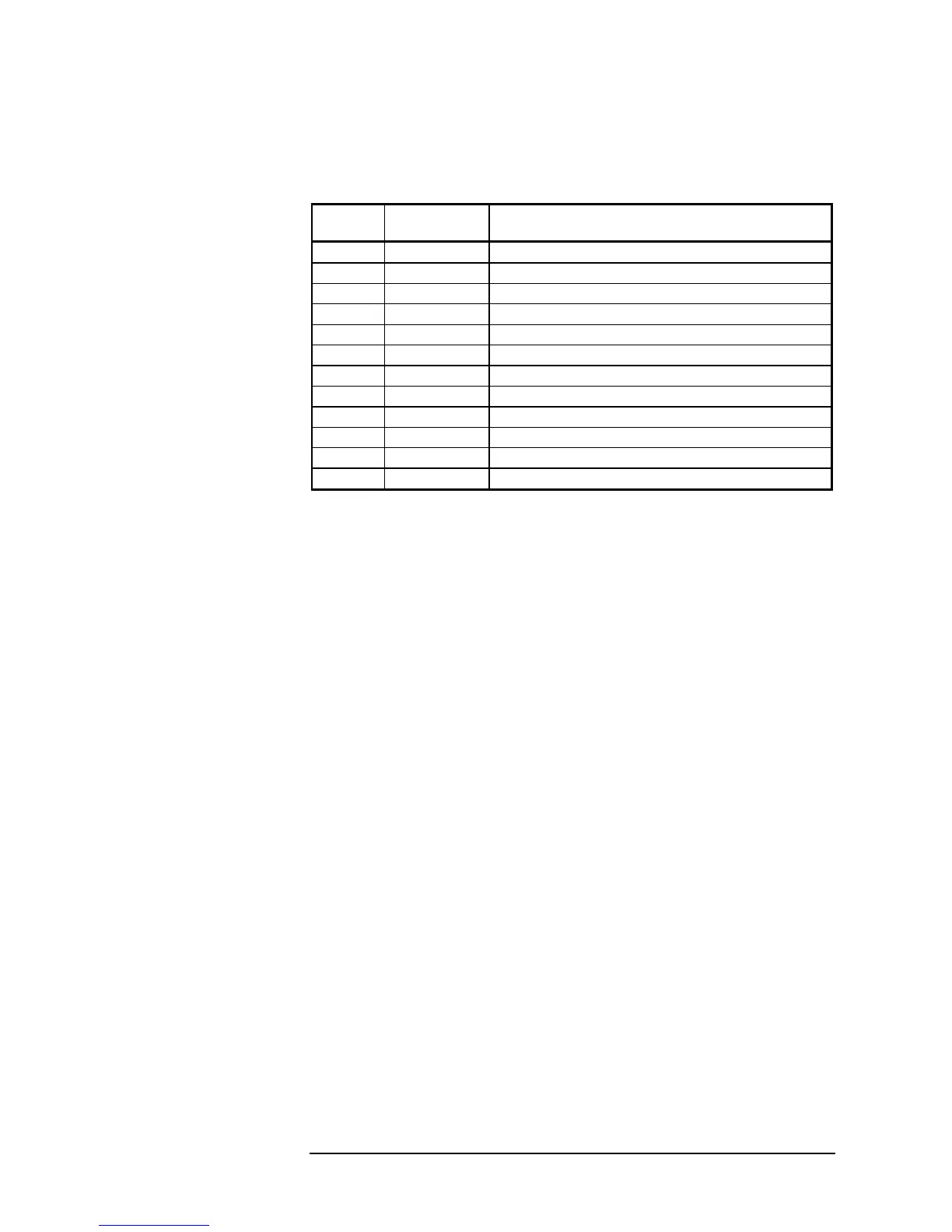

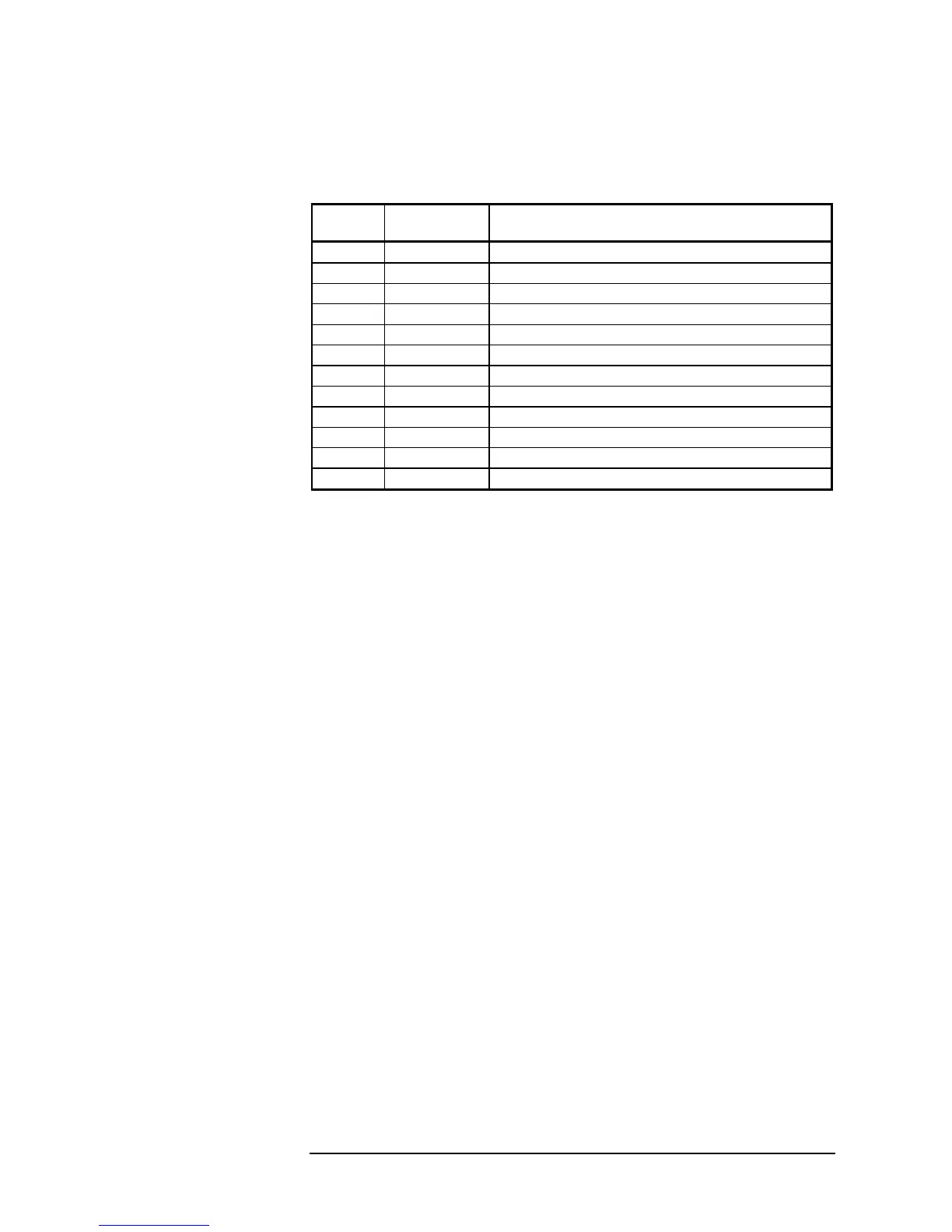

Table 12: Programmable Module Dynamic Items for Controller

Algorithms

Item Tag Item Address

(Hex/Dec)

Description

OCM1 0A/10 Output of Programmable Module 1

OCM2 0B/11 Output of Programmable Module 2

OCM3 0C/12 Output of Programmable Module 3

OCM4 0D/13 Output of Programmable Module 4

OCM5 0E/14 Output of Programmable Module 5

OCM6 0F/15 Output of Programmable Module 6

WSP1 10/16 Working Set Point of Control Module 1

WSP2 11/17 Working Set Point of Control Module 2

WSP3 12/18 Working Set Point of Control Module 3

WSP4 13/19 Working Set Point of Control Module 4

WSP5 14/20 Working Set Point of Control Module 5

WSP6 15/21 Working Set Point of Control Module 6

When a programmable module is configured as Algorithm 1 (Item

PMxTYP, bits 5…1 = 00001), the module performs the function of an

on/off controller.

When a programmable module is configured as Algorithm 2 (Item

PMxTYP, bits 5…1 = 00010), the module performs the function of a PI

controller.

When a programmable module is configured as Algorithm 3 (Item

PMxTYP, bits 5…1 = 00011), the module works with the next

programmable module (PMx

+1

) as a heating/cooling on/off controller

with a single output. The output of the second module (Loop 2) follows

the output of the first module (Loop 1).

Loop 1 must be configured as a heating controller (reverse acting) and its

working set point must always be lower than the working set point of

Loop 2, which must be configured as a cooling controller (direct acting).

The two modules share the process variable of Loop 1. Loop 1 is active

when the process variable is below the working set point of Loop 1, and

Loop 2 is active when the process variable is above the working set point

of Loop 2. The changeover takes place in the center of the control dead-

band between the two loops with a 10% switching differential.

Dynamic

Parameters for

Controller

Algorithms

Algorithm 1:

On/Off Controller

Algorithm 2:

PI Controller

Algorithm 3:

Heating/Cooling

On/Off Controller

– Single Output

Loading...

Loading...