|

45

VIKING 4G E, S

Rev. 1.0 (29.1.2020)

Installation

6.8.1. Water connection and quality requirements

• The unit must be connected to the cold and warm water supply and, if fi tted with a twin water con-

nection option (T), also to the soft water supply.

• All water supply lines must be fi tted with a one-way valve and a shut-off valve (not included in delivery).

• Before connection to the unit all water lines must be thoroughly rinsed from all loose particles.

• The water pressure range for optimum performance is 250 - 600 kPa.

• The minimum water pressure allowed for proper function of the unit is 250 kPa. If the pressure is

lower, a pressure rise pump must be fi tted by the customer.

• The minimum water fl ow rate in the kettles is 5 l/min. To ensure optimal operation of the unit, it is

recommended cold water fl ow rate must be at least 20 l/min.

• All water connections are of size Ø15mm (R 1/2”).

• The size of particles in the water must not exceed 15 μm

• Water conductivity should be below 1000μS/cm. Already when the conductivity is over 500μS/cm, a

water analysis is recommended.

• Maximum chloride concentration allowed is 60 mg/l.

• Maximum chlorine concentration allowed is 0,2 mg/l.

• The pH value of the water should be between 6,5 and 9,5.

• The water hardness should be less than 6 ° dH. Water hardness must not exceed 9 ° dH. If the hard-

ness of the water is between 6-9 ° dH, it increases the need for cleaning the steam generator and

shortens the lifespan of heating resistors.

• Unit damages caused by chloride, chlorine or pH values exceeding the stated limits are not covered

by manufacturer warranty.

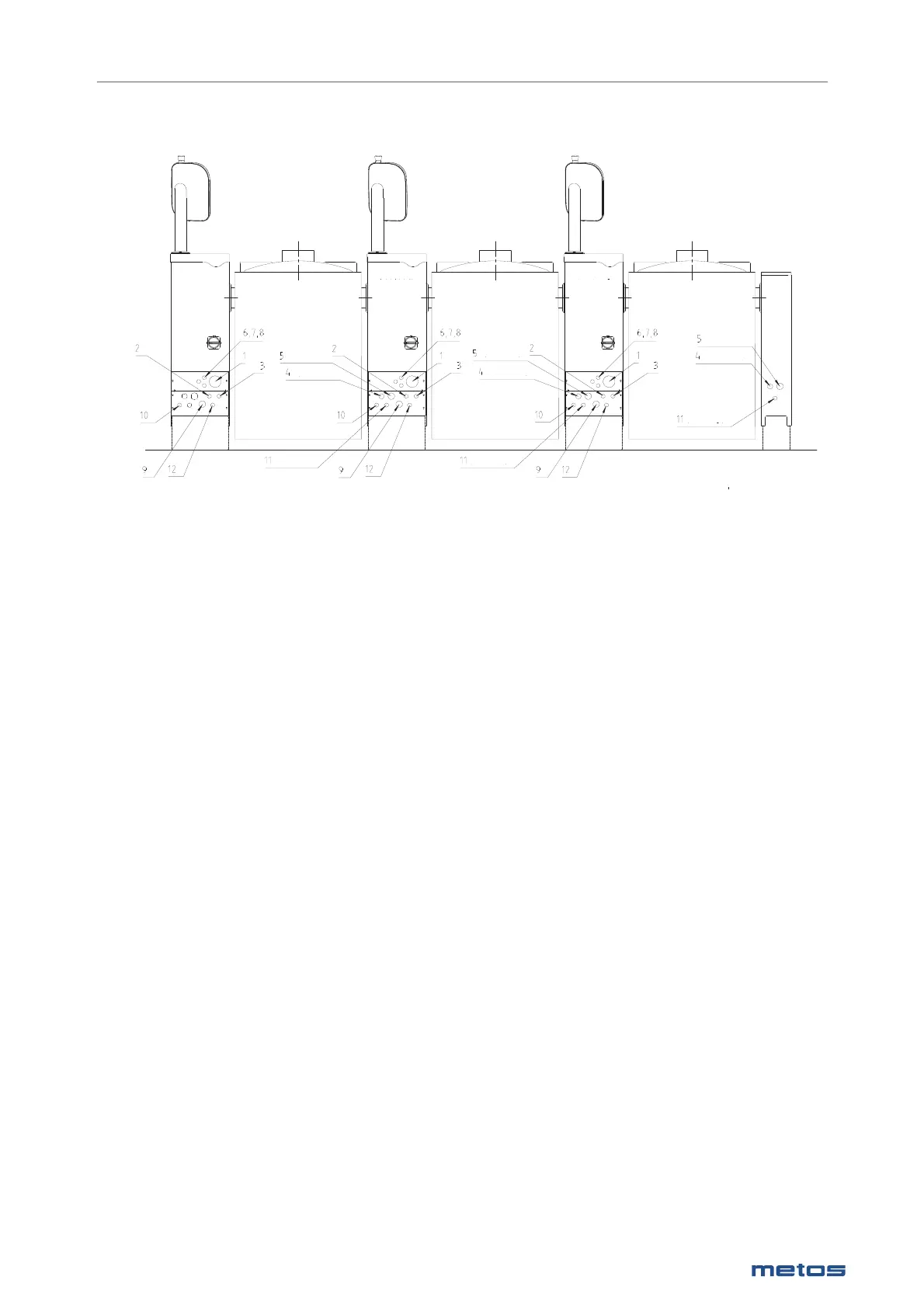

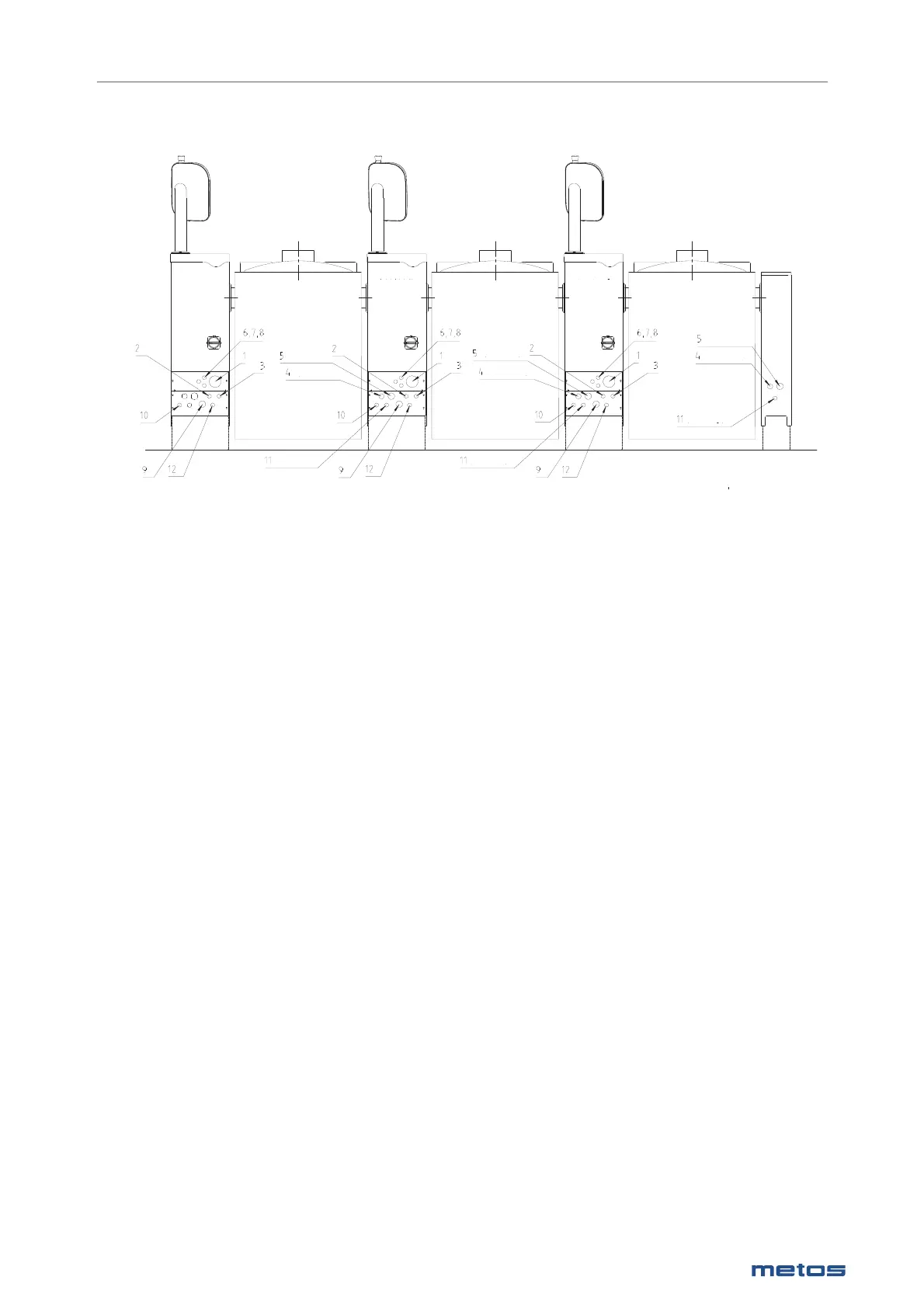

1. Electrical power supply cable, PG21/PG36/PG42 gland

2. Cold water connection R1/2” ( ø15 ). Must be fi tted with a one way valve and shut off valve.

3. Hot water connection R1/2” ( ø15 ). Must be fi tted with a one way valve and shut off valve. (option)

4. Ice bank cooling inlet R3/4”. Max. pressure 3 BAR, fl ow 90l/min. (option)*

5. Ice bank cooling outlet R1”. (option)*

6. Ice bank cooling control cable 4 x 0,75mm (option).*

7. HACCP cabling (option).

8. Power management system control cable (option).

9. Steam inlet R3/4” / R1” / R1 1/4” (option)

10. Condensate outlet R1/2” / R3/4” (option)

11. Compressed air inlet R1/2” max pressure 1,3 bar, minimi fl ow 30 l/min (option)*

12. Twin water inlet R1/2”(option)

* Proveno kettles only

An example of connections in a kettle group

KETTLE 1

KETTLE 1

(KETTLE 1)

(KETTLE 1)

(KETTLE 1)

KETTLE 2

(KETTLE 2)

(KETTLE 2)

(KETTLE 2)

KETTLE 3

(KETTLE 3)

(KETTLE 3)

(KETTLE 3)

KETTLE 3

KETTLE 2

Loading...

Loading...