3: Operating Procedures

22 U3000/U4000 User Manual

(Issue 2.0)

3.3.3 Adjusting the calibration factor

With the system running:

1. Stop (Stall) the totaliser facility and zero it (Paragraph 3.5

).

2. Run the totaliser to measure the total flow over a 30-60 minute period, and note the total flow indicated by

the reference flow meter over the same period.

3. Calculate the % error between the U3000/U4000 instrument and reference meters. If the error is greater

than ±1% calibrate the U3000/U4000 as detailed below.

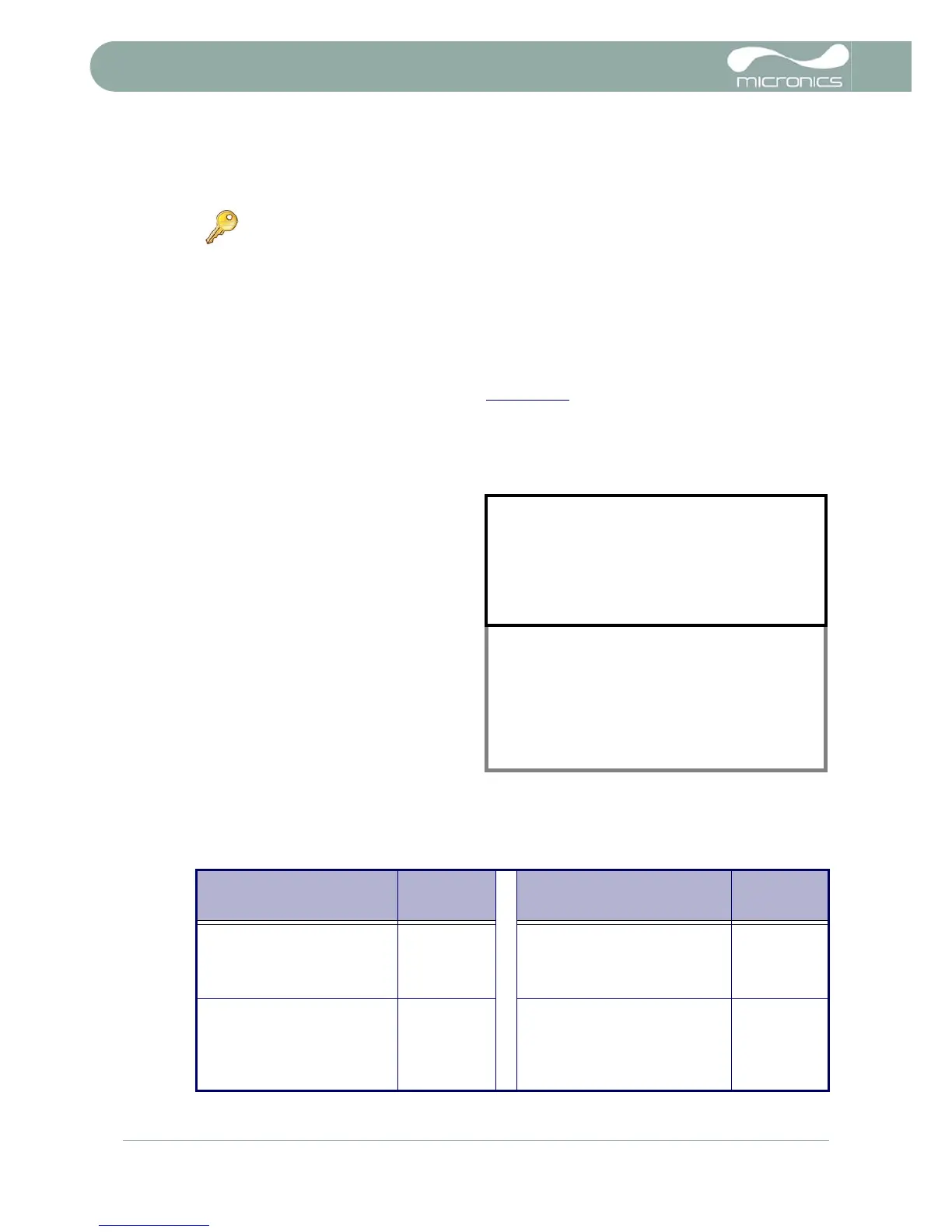

4. Press the Options key to access the

FLOW READING OPTION screen shown.

5. Scroll down and select Calibration

factor then press ENTER.

6. Change the calibration factor according to

the error calculated in step 3. For example,

if the instrument was reading 1% high then

increase the Calibration factor value

by 0.010. Conversely, if the reading is 1%

low then decrease the calibration factor to

0.990.

7. Press ENTER to apply the change.

8. Select Roughness factor or Exit as

required and press ENTER.

3.3.4 Adjusting the roughness factor

The roughness factor compensates for the condition of the internal pipe wall, as a rough surface will cause

turbulence and affects the flow profile of the liquid. In most situations it is not possible to inspect the pipe

internally and the true condition is not known. In these circumstances experience has shown that the

following values can be used:

Key Point: USE THIS FACILITY WITH CARE & ONLY WHERE NECESSARY

The instrument is fully calibrated before leaving the factory and under normal cir-

cumstances does not require further calibration when used on site.

This facility can be used to correct the flow indication where unavoidable errors occur

due to the lack of a straight pipe or where the sensors are forced to be fitted close to

the pipe-end, valve, junction etc.

Any adjustment must be made using a reference flowmeter fitted in the system.

Pipe Material Roughness

Factor

Pipe Material Roughness

Factor

Non ferrous metal

•Glass

• Plastics

•Light metal

0.01 Welded steel pipes, new:

• Long usage, cleaned

• Lightly and evenly rusted

• Heavily encrusted

0.1

Drawn steel pipes:

• Fine planed, polished

surface.

• Plane surface

• Rough planed surface

0.01 Cast iron pipes:

• Bitumen lining

• New, without lining

• Rusted / Encrusted

1.0

FLOW READING OPTION DD-MM-YY HH:MM:SS

Data review

Zero Cutoff (m/s) : 0.010

Set zero flow (m/s) : 0.000

Damping (secs) : 10

Totaliser : Run

Reset +Total

Reset –Total

Calibration factor : 1.000

Roughness factor : 0.010

Alarm Settings :

Max Pulse Freq (Hz) : 10.00

Flow at Max Frequency : 200.00

Calculated Pulse Value: 2.00

Diagnostics

Exit

Loading...

Loading...