2-10

ARC-6000

98-05012

R3

C. Write this number down for future reference. This is

the number to use for these specific conditions

(product and applicator configuration).

Fine tuning of the calibration number can also be done

based on field experience. If liquid is consistently left

over after applying on a known number of acres, adjust

the calibration number up slightly. If there is consistently

too little material to cover the desired acres, adjust the

calibration number down slightly.

Setting The HOLD/CLOSE Response

T

he operator can select either a "HOLD" or

"CLOSE" response of the Flow Control Valve to

both the Implement Status Switch and to an “ All

Booms OFF" condition. These responses are independent

of each other, allowing the operator to select a "HOLD"

condition for one and a "CLOSE" for the other. Careful

consideration should be given to both conditions and the

response selected for your application.

IMPLEMENT STATUS S WITCH

When the "HOLD" condition is selected, opening the

Implement Status Switch causes the Flow Control Valve

to hold in its current position. When the Implement Status

Switch is closed the Flow Control Valve is already open

and product flow is instantaneous. This response assumes

that some other device, such as a boom section valve, has

stopped the product flow.

When the "CLOSE" condition is selected, opening the

Implement Status Switch automatically causes the Flow

Control Valve to close. This response is preferred when it

is necessary to use the Flow Control Valve to stop the

product flow.

Use the following procedure to set the Status Switch

response.

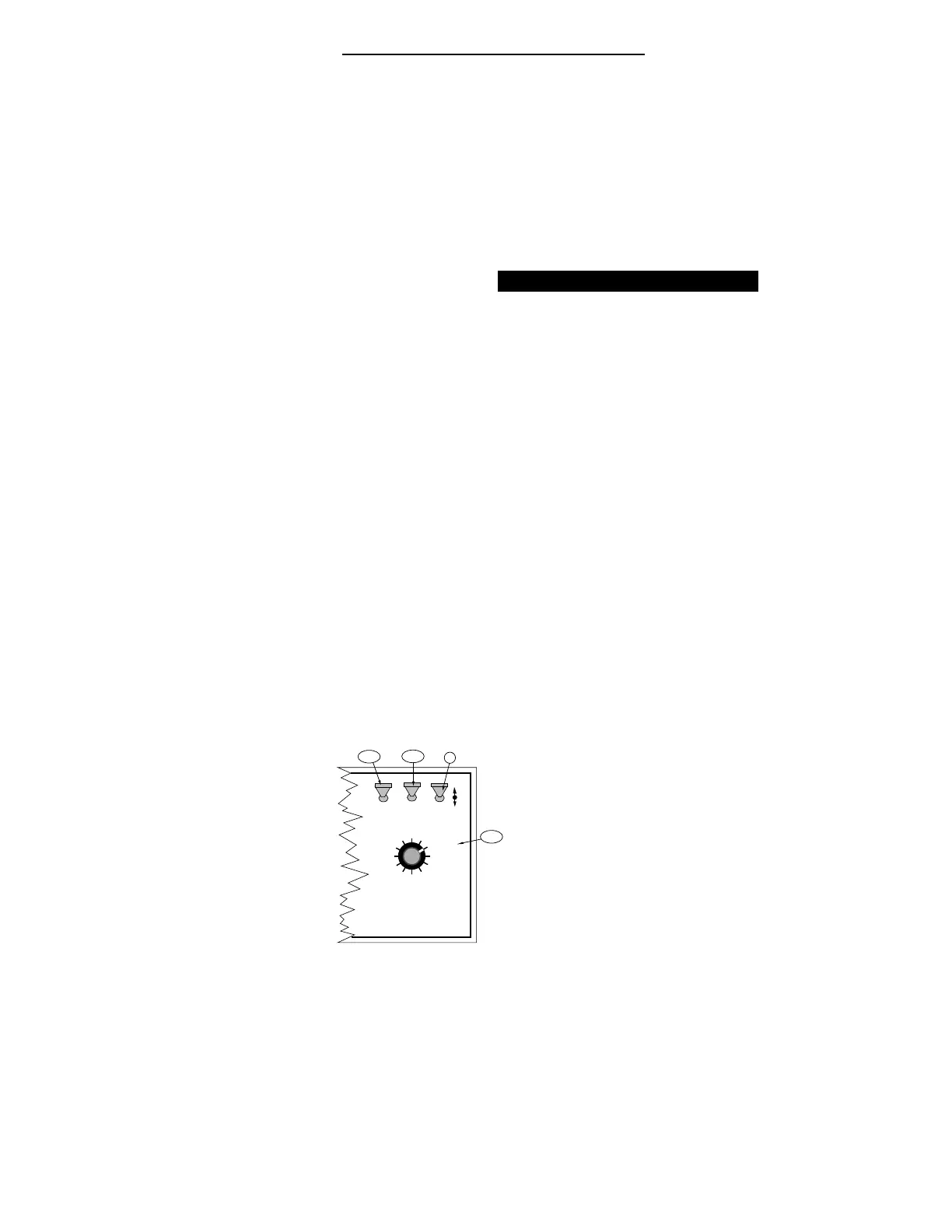

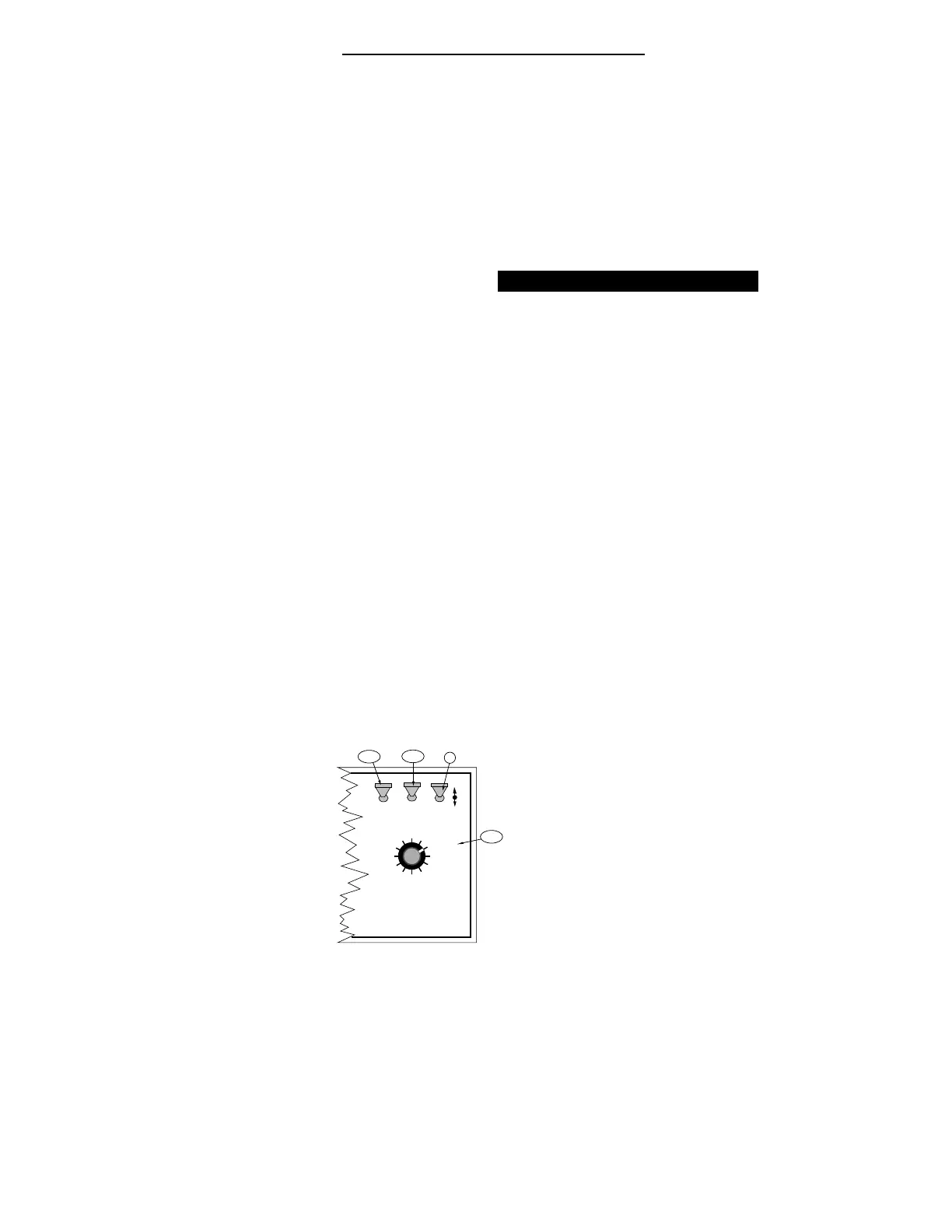

A. Set the Console to the following positions;

1. Power “ ON”

2. Mode Selector “ OPERATE”

3. Display Selector “ TOTAL APPLIED”

DISPLAY SELECTOR

Speed

Field Area Impl. Width

Distance

Test

Speed

Prime

Total Applied

Application Rate

OFF SET- UP DEC.

ON

OPERATE INC.

Scan

Product Vol.

Total Area

BOOMS

123456789

% Rate

C

A-1

A-2

A-3

Loading...

Loading...