OM-492 Page 13

Return To Table Of Contents

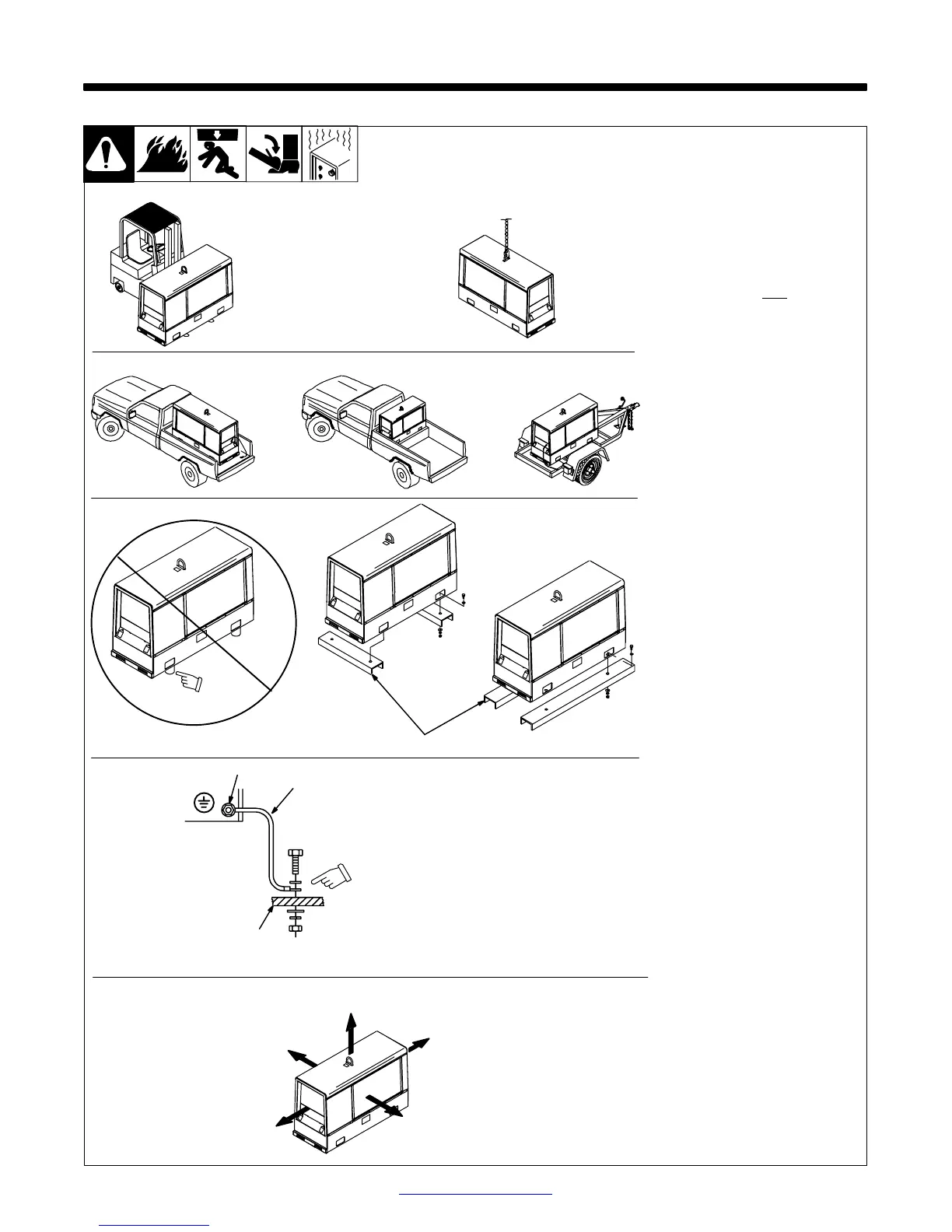

SECTION 5 − INSTALLATION

install2 5/03 − Ref. 800 652 / Ref. 800 477-A / 803 274

Do not weld on base. Welding

on base can cause fuel tank fire

or explosion. Bolt unit down

using holes provided in base.

Always securely fasten weld-

ing generator onto transport

vehicle or trailer and comply

with all DOT and other applica-

ble codes.

Do not mount unit by support-

ing the base only at the four

mounting holes. Use cross-

supports to adequately sup-

port unit and prevent damage

to base.

Always ground generator

frame to vehicle frame to pre-

vent electric shock and static

electricity hazards.

If unit does not have GFCI re-

ceptacles, use GFCI-protected

extension cord.

Mounting:

1 Cross-Supports

Mount unit on flat surface or use

cross-supports to support base.

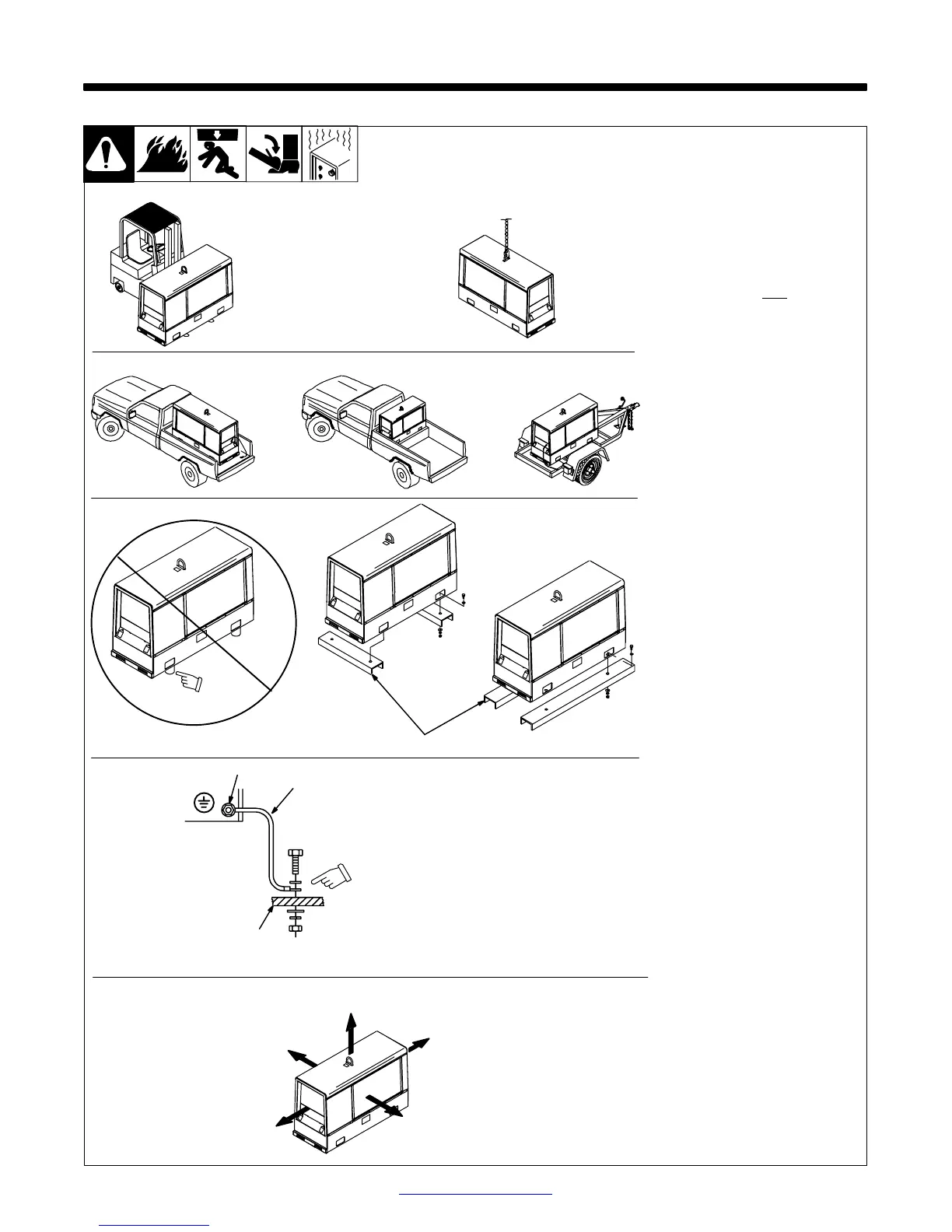

Grounding:

2 Equipment Grounding Terminal

(On Front Panel)

3 Grounding Cable (Not Supplied)

4 Metal Vehicle Frame

Connect cable from equipment

ground terminal to metal vehicle

frame. Use #10 AWG or larger insu-

lated copper wire.

Electrically bond generator frame to

vehicle frame by metal-to-metal contact.

GND/PE

2

3

4

OR

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

18 in

(460 mm)

OR

Movement

Airflow Clearance

Location

Grounding

Do not lift unit from end.

5-1. Installing Welding Generator

Mounting

1

Inadequate support.

Do not use flexible mounts.

OR

Bed liners, shipping skids, and some running

gears insulate the welding generator from the

vehicle frame. Always connect a ground wire

from the generator equipment grounding termi-

nal to bare metal on the vehicle frame as shown.

OR

Loading...

Loading...