OM-492 Page 44 Return To Table Of Contents

SECTION 10 − RUN-IN PROCEDURE

run_in4 8/0

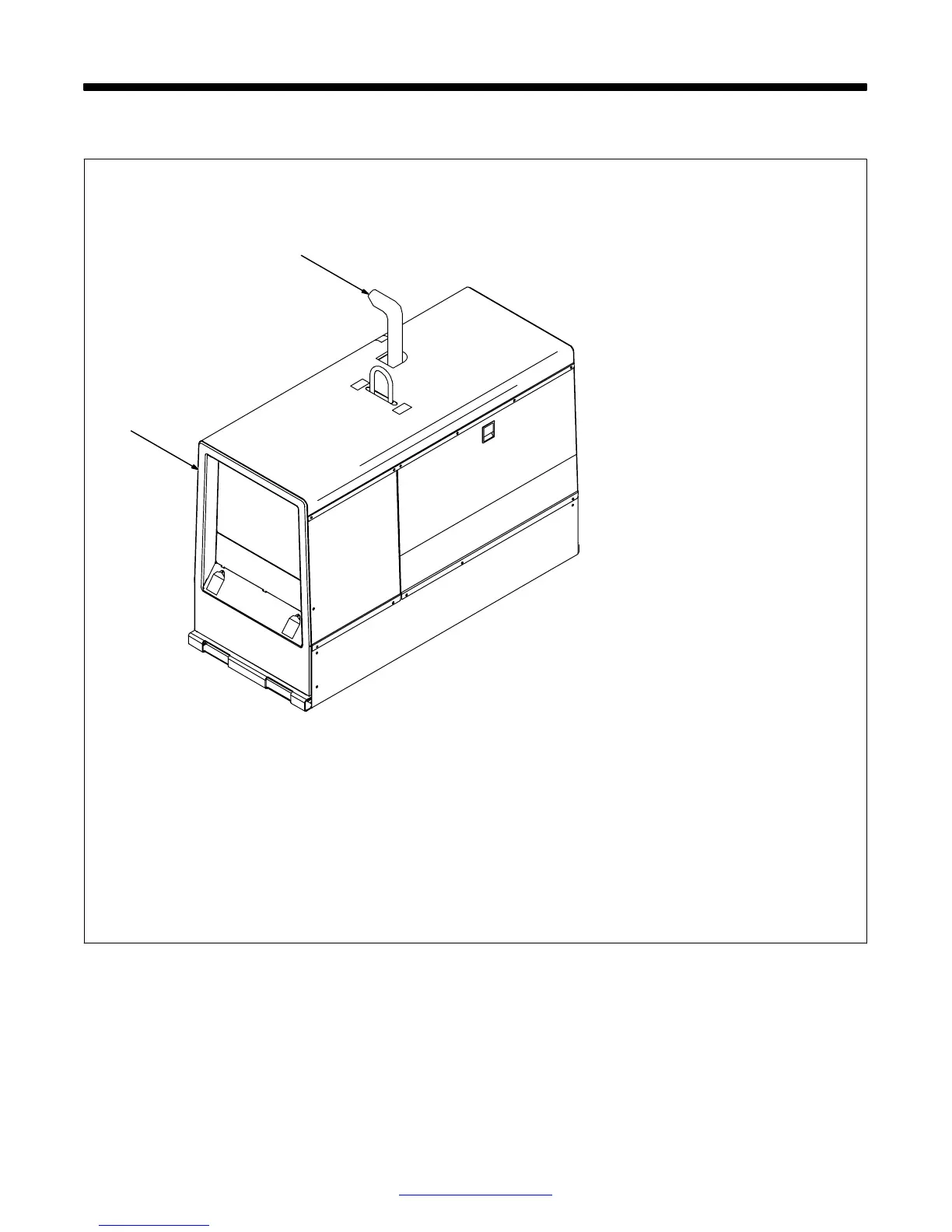

10-1. Wetstacking

2

1

Do not perform run-in

procedure at less than 20

volts weld output and do not

exceed duty cycle or equip-

ment damage may occur.

1 Welding Generator

Run diesel engines near rated volt-

age and current during run-in period

to properly seat piston rings and

prevent wetstacking. See name-

plate, rating label, or specifications

section in this manual to find rated

voltage and current.

Do not idle engine longer than

necessary. Piston rings seat

faster if engine runs at weld/

power rpm, and the welding

generator is kept loaded during

run-in.

2 Engine Exhaust Pipe

Wetstacking is unburned fuel and

oil in the exhaust pipe and occurs

during run-in if the engine is run too

long at light load or idle rpm.

If exhaust pipe is coated with a wet,

black, tar-like substance, dry the

engine using one of the following

run-in procedures.

See the engine manual for addition-

al engine run-in information.

Loading...

Loading...