OM-492 Page 51Return To Table Of Contents

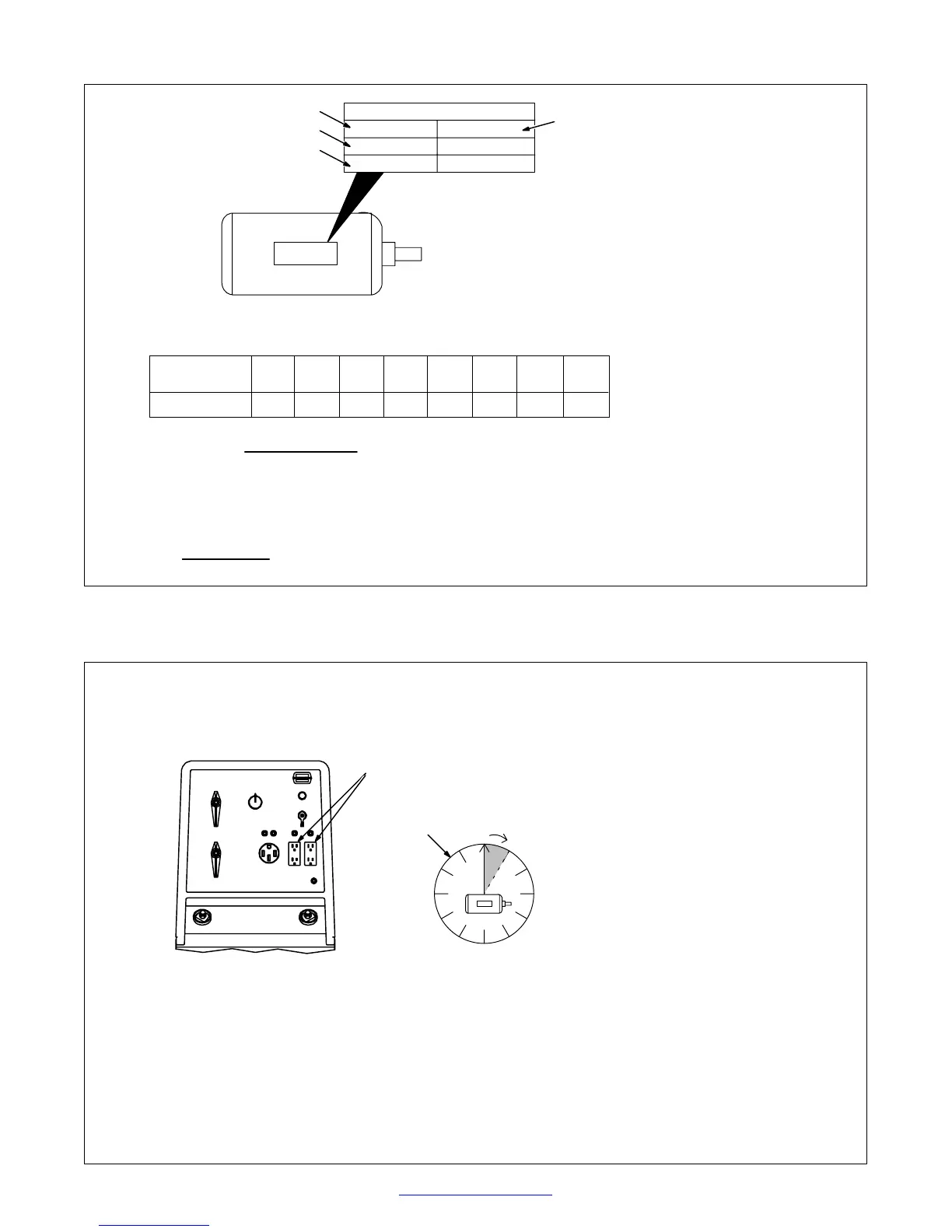

11-8. Power Required To Start Motor

S-0624

1 Motor Start Code

2 Running Amperage

3 Motor HP

4 Motor Voltage

To find starting amperage:

Step 1: Find code and use table to

find kVA/HP. If code is not listed,

multiply running amperage by six to

find starting amperage.

Step 2: Find Motor HP and Volts.

Step 3: Determine starting amper-

age (see example).

Welding generator amperage out-

put must be at least twice the

motor’s running amperage.

VOLTS AMPS

HP

230 2.5

1/4

Hz

PHASE

CODE 60

1

M

AC MOTOR

1

2

3

4

Single-Phase Induction Motor Starting Requirements

Motor Start

Code GHJKLMNP

KVA/HP 6.3 7.1 8.0 9.0 10.0 11.2 12.5 14.0

EXAMPLE: Calculate the starting amperage required for a 230 V, 1/4

HP motor with a motor start code of M.

Starting the motor requires 12.2 amperes.

11.2 x 1/4 x 1000

230

= 12.2 A

kVA/HP x HP x 1000

VOLTS

= STARTING AMPERAGE

Volts = 230 HP = 1/4 Using Table, Code M results in kVA/HP = 11.2

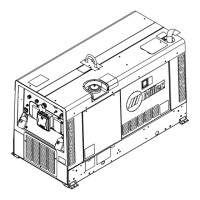

11-9. How Much Power Can Generator Supply?

Ref. ST-800 396-A / S-0625

1 Limit Load To 90% Of

Generator Output

Always start non-resistive (motor)

loads in order from largest to small-

est, and add resistive loads last.

2 5 Second Rule

If motor does not start within 5

seconds, turn off power to prevent

motor damage. Motor requires

more power than generator can

supply.

1

2

Loading...

Loading...