M800W/M80W Series Connection and Setup Manual

25 Setting the Position Detection System

484

IB-1501268-K

There are two kinds of position detection system: one is "relative position detection", which establishes the reference

position (zero point) at every CNC power-ON; the other is "absolute position detection", which allows to start the

operation without establishing the reference position (zero point) again after the CNC power-ON.

25.1 Adjusting the Absolute Position Detection System

There are four types of the absolute position zero point initial setting: "marked point alignment method", "marked point

alignment method II", "machine end stopper method", and "dog-type".

Set the parameter "#2049 type (Absolute position detection method)" for the type and method of absolute position zero

point initial setting.

The required components differ depending on the detection method.

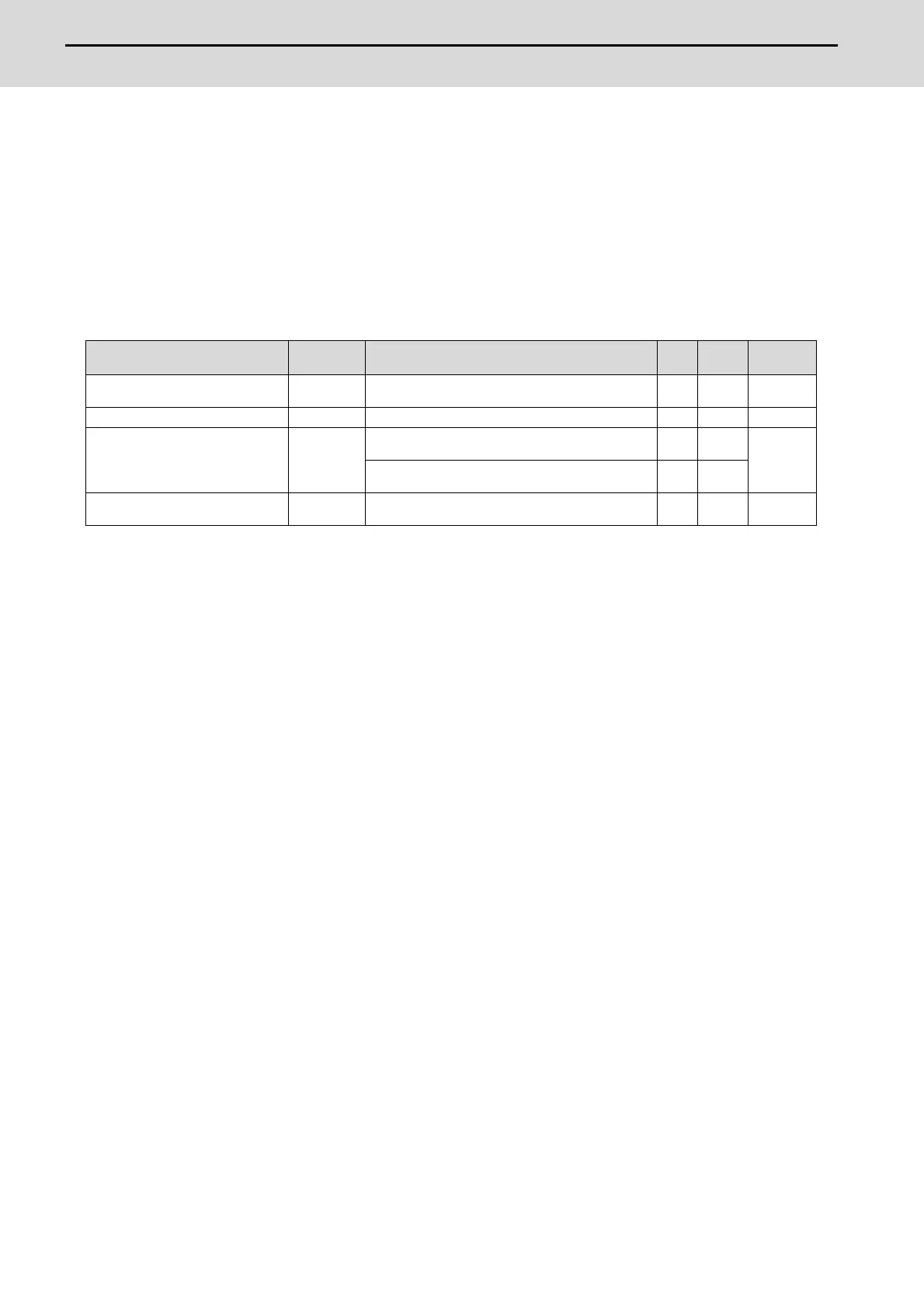

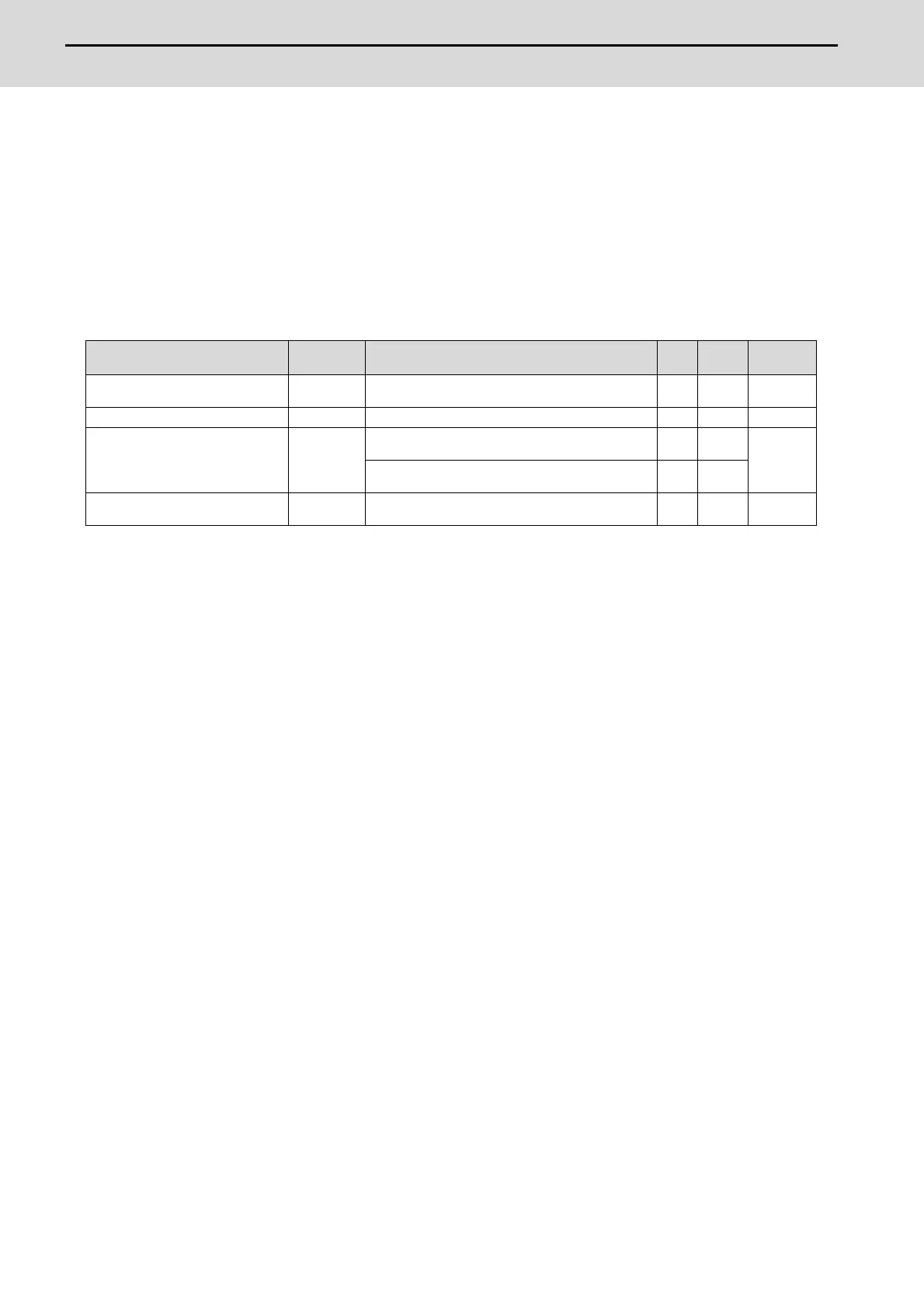

[Characteristics of each method]

(1) Marked point alignment method I

Align the table side’s mark and the machine side’s mark.

The first grid point which is returned from the marks are aligned is determined as the basic position.

Because the first grid point which is returned from the marks are aligned is determined as the basic position, the

reproducibility is kept even the position information is lost due to runnning out of battery etc.

(2) Marked point alignment method II

Align the table side’s mark and the machine side’s mark.

The position where the marks are aligned is determined as the basic position.

Because the position where the marks are alinged is determined as the basic position, the reproductivity is low if the

position information is lost due to running out of battery etc.

(3) Machine end stopper method

Push the table against the machine end stopper.

[When #2059 zerbas = 0]

The position where the table is pushed against the machine end stopper is determined as the basic position.

[When #2059 zerbas = 1]

The first grid point which is returned from the position where the table is pushed against the machine end

stopper is determined as the basic position.

There are two types of the machine end stopper method: automatic initialization and manual initialization.

When the automatic initialization is applied, the axis travels automatically after the JOG is started.

When the manual initialization is applied, the axis travels by handle mode or JOG mode while confirming each

operation.

(4) Dog method

This method requires a dog sensor.

Move the table until the dog is kicked, and the first grid point after the dog OFF is determined as the basic position.

Method

Required

component

Basic position

#2049

type

#2059

zerbas

Reference

Marked point alignment method I

None

The first grid point which is returned from the position where

the mark is aligned.

2 1 25.1.1

Marked point alignment method II

None The position where the marks are aligned.

4 0 25.1.2

Machine end stopper method

Machine end

stopper

The position where the table is pushed against the machine

end stopper.

10

25.1.3

25.1.4

The first grid pointed which is returned from the position

where the table is pushed against the machine end stopper.

11

Dog type

Dog,

dog-sensor

The first grid point after the dog OFF.

3 0 25.1.5

Loading...

Loading...