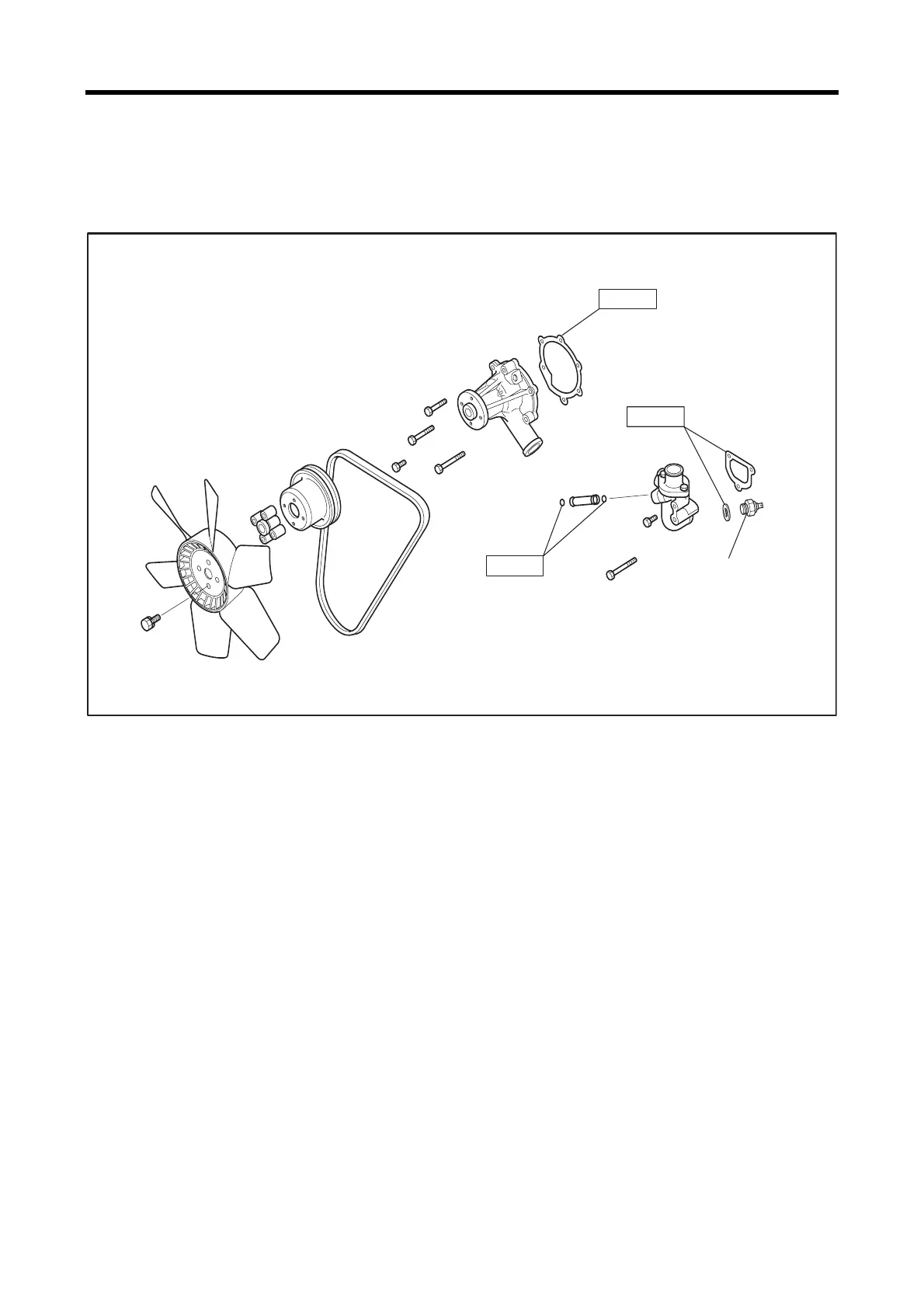

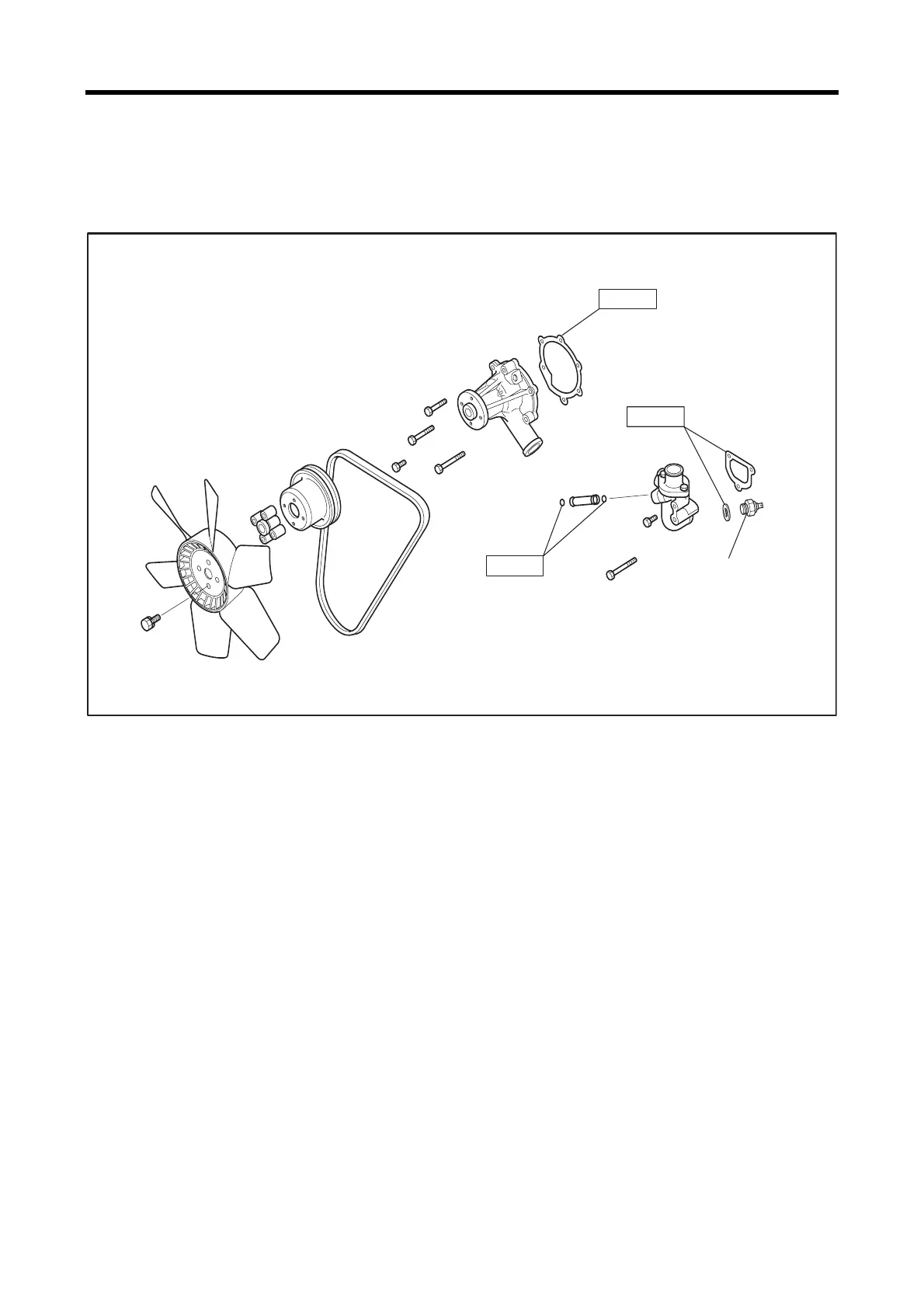

COOLING SYSTEM

10-5

3. Installing cooling system

3.1 Installing cooling fan, fan pulley, V-belt, thermostat, thermoswitch

and water pump

Installing cooling fan, fan pulley, V-belt, thermostat, thermoswitch

and water pump

Replace

Replace

Replace

19.6 to 29.4 N㨯m

{2.0 to 3.0 kgf㨯m}

[14 to 22 lbf㨯m]

Loading...

Loading...