CHAPTER 3: USING UNIFLOW

®

2 PROGRAMMING FUNCTIONS

UNIFLOW

®

2 PULSED THERMODE CONTROL

990-228 3-3

Reflow

You use the

Reflow period to actually melt the solder for a reflow solder joint, or set thermoplastic or

thermoset conductive adhesives for a heat-seal joint.

NOTE: The Reflow temperature will always be higher than the actual melting point of the solder or

heat seal adhesives due to heat losses in both the thermode and parts.

Reflow is shown as having a time-at-temperature of 3.0 seconds and a set-point temperature of 350qC.

Time-at-temperature can be set for 0.1 to 99.9 seconds. Set-point temperature can be set from 60qC to

600qC.

Cool

You use

Cool to ensure that a solder joint or heat seal adhesive has solidified. An air actuated reflow

soldering head or a heat seal head retracts the thermode from the parts upon reaching the

Cool

temperature. The Cool parameter shows 180qC. The

Cool time is not controlled.

Profile Number

The large 1 shown at the right-hand side of the screen is the number of the currently displayed heat

profile. The number of the profile to be displayed is selected with the

PROFILE NUMBER keys and

may range from 1 to 15.

Present Temperature

The present temperature of the thermode, shown in the example screen as 40C, is displayed in the upper

right-hand corner of the graphic screen.

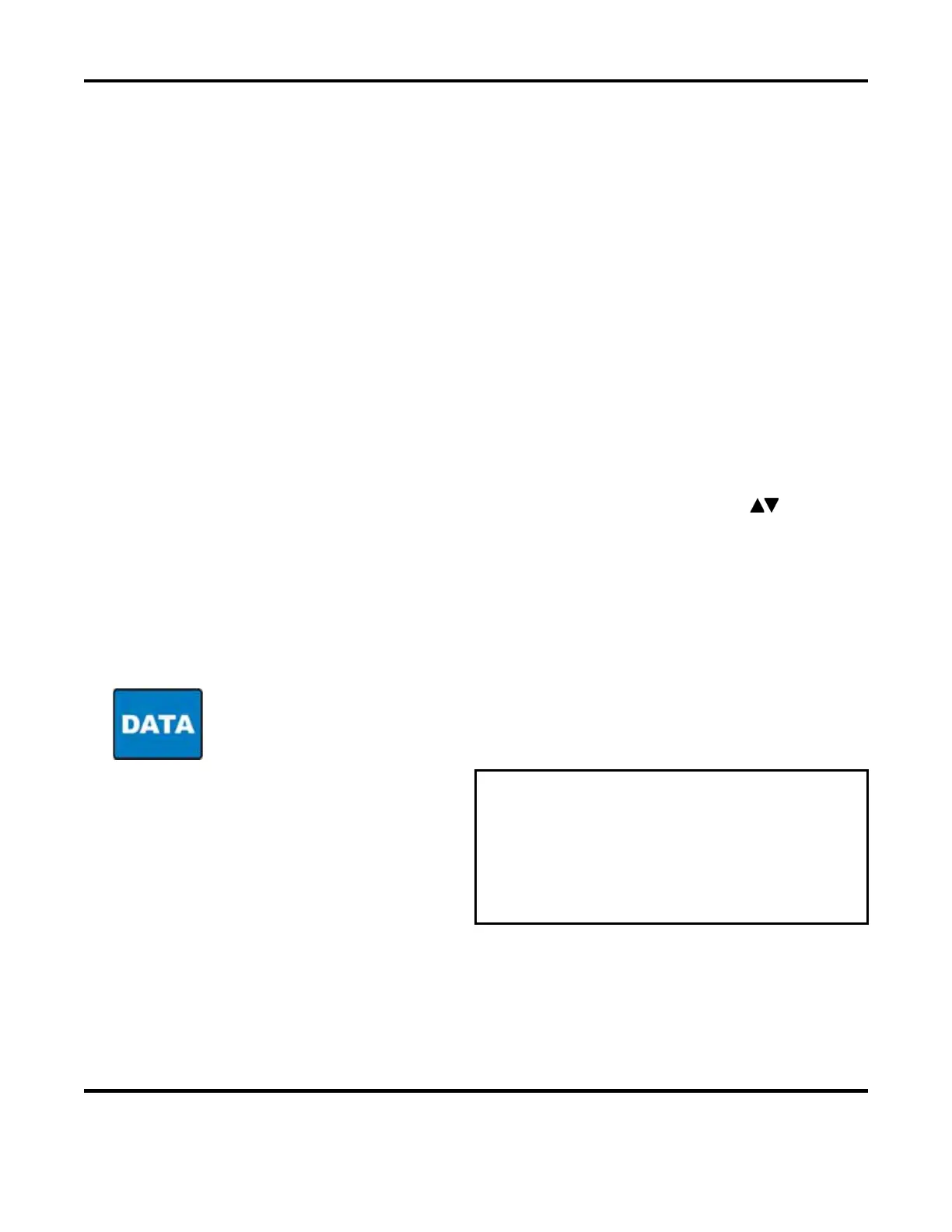

DATA Key

The DATA key brings up the data screen to the display. The data screen reports the

most recent heat cycle parameters in numerical format: time, temperature, and

counter status (when enabled).

You may initiate the HEAT cycle while the DATA

screen (rather than the graphic screen) is

displayed.

TEMPERATURE: Thermode= 40

C

Peak= 354

C Final=351

C Average=349

C

TIME: (Seconds) Preheat = 01.0 Rise = 01.0

Heat= 03.0 Cool= 05.5 Total= 009.5

PROFILE: 2 RATE=Medium

System Ready

Reflows before cleaning = +000100

Reflows before replacement = +000500

Loading...

Loading...