13

bracket and into the side of the wheel pant. Do this

for both wheel pants. See photo # 20 below.

Photo # 20

PARTS REQUIRED

q {2} Nylon Motor Mount Beams

q {8} 3mm x 20mm Machine Screws

q {16}3mm Flat Washers

q {8} 3mm Nylon Insert Nuts

MOUNTING ENGINE TO MOTOR MOUNT

q 1) Using a clamp or a vise, align the two motor

mount beams and clamp them together. The beam

halves are universal and the webbing should face the

outside edges. See photo # 21 below.

Photo # 21

q 2) Mark the locations of the four engine mount-

ing holes on the beams using a pencil. For the engine

to align properly with the cowling, it is important that

the front edge of the engine's drive washer be 3-5/8”

forward from the rear edge of the mounting beams.

q 3) When satisfied with the alignment of the en-

gine, remove the beams from the clamp and drill 1/8”

holes through the mounting beams at the four engine

mounting hole locations.

q 4) Mount the engine to the mounting beams us-

ing the four 3mm x 20mm machine screws, eight 3mm

flat washers and four 3mm lock nuts. Tighten the

screws and nuts completely.

If using an engine equipped with a remote needle

valve we recommend mounting the needle valve

to the engine prior to installing the engine on the motor

mount beams.

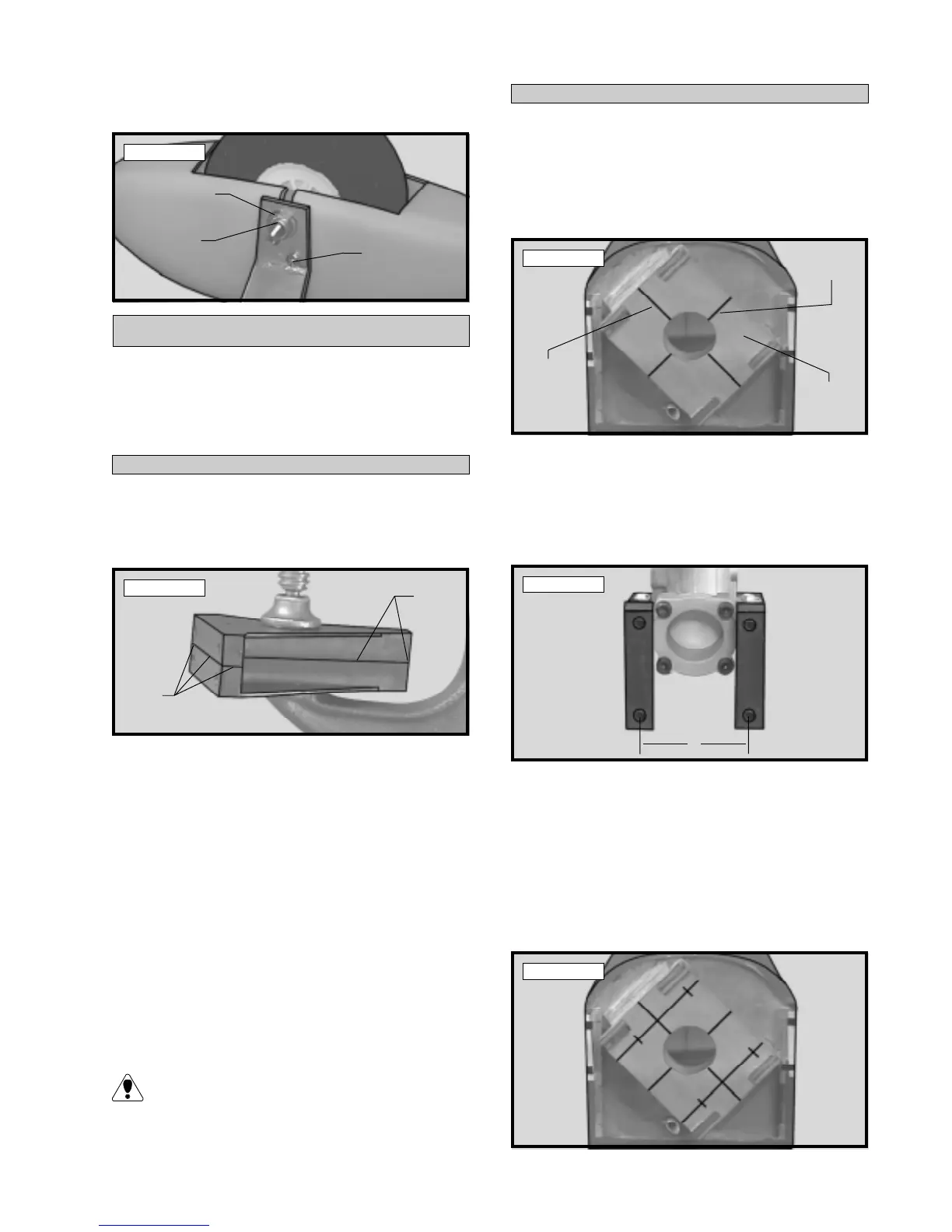

ALIGNING THE MOTOR MOUNT

q 5) The engine is mounted at a 45º angle in rela-

tion to the firewall. The motor mount beams should

be parallel with sides of the engine mounting box.

Using a ruler and a pen, measure and draw a vertical

centerline and a horizontal centerline on the engine

mounting box. See photo # 22 below.

Photo # 22

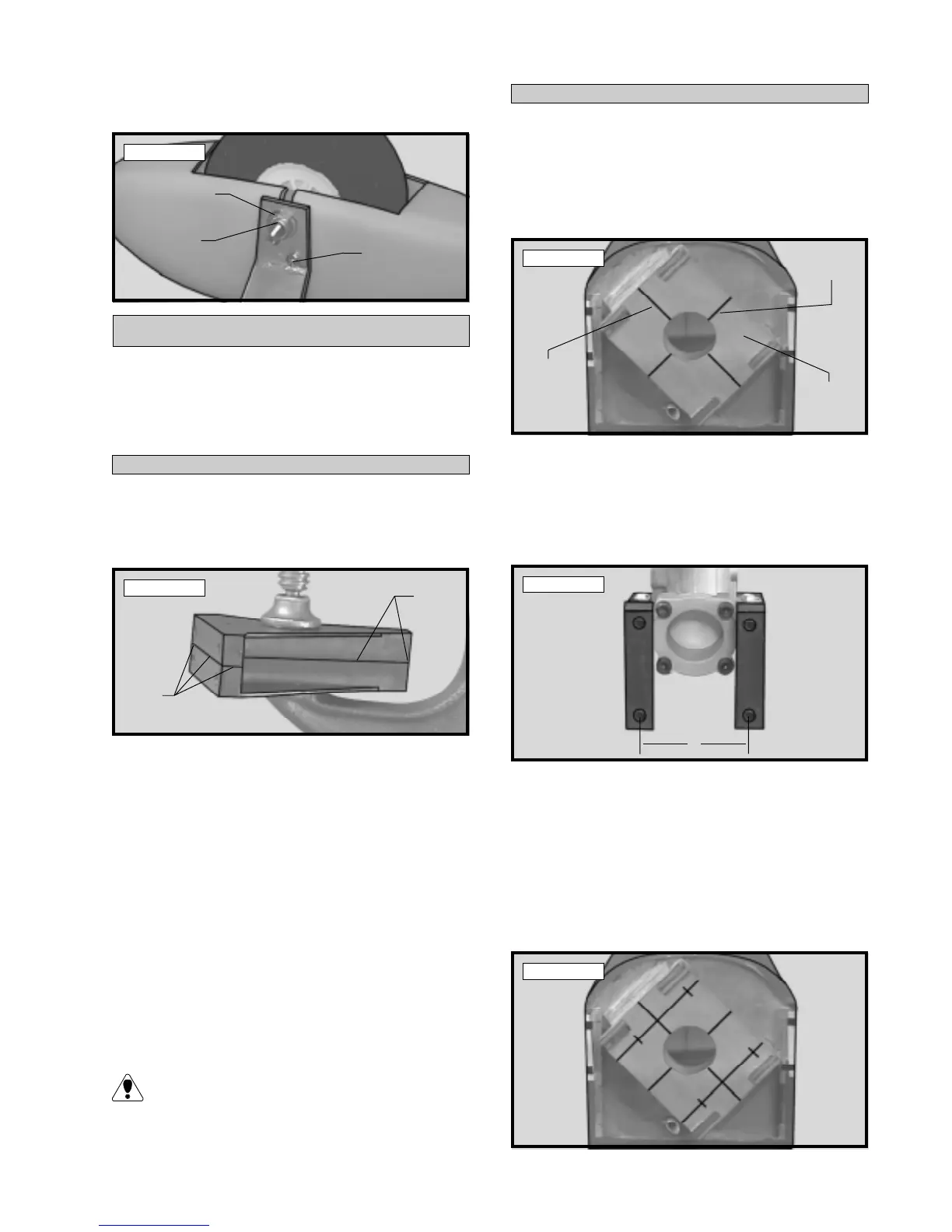

q 6) With your engine still installed on the motor

mount beams, use a ruler and measure the width be-

tween the predrilled mounting holes in the motor

mount. This distance will vary depending on the brand

and size of the engine you have chosen. See photo #

23 below.

Photo # 23

q 7) Divide the measurement found in step # 6

in half. Measure this resulting distance and draw

one vertical line to the right and one to the left of the

vertical centerline.

q 8) On the two vertical lines you just drew, mea-

sure and place two marks 1/2” below and two marks

13/16” above the horizontal centerline (looking at the

firewall). See photo # 24 below.

Photo # 24

ENGINE MOUNTING

Wood Screw

Nylon

Insert

Nut

Flat Washer

Align

Even

Align

Even

Vertical

Centerline

Horizontal

Centerline

Engine

Mounting

Box

D

D = Distance

Between

Predrilled Motor

Mount Holes

Loading...

Loading...