16

q 5) Test fit the throttle servo in the preinstalled

servo tray behind the forward bulkhead. The servo

should be mounted with the output shaft towards the

right side of the airplane.

Because the size of servos differ, you may need

to adjust the size of the precut opening.

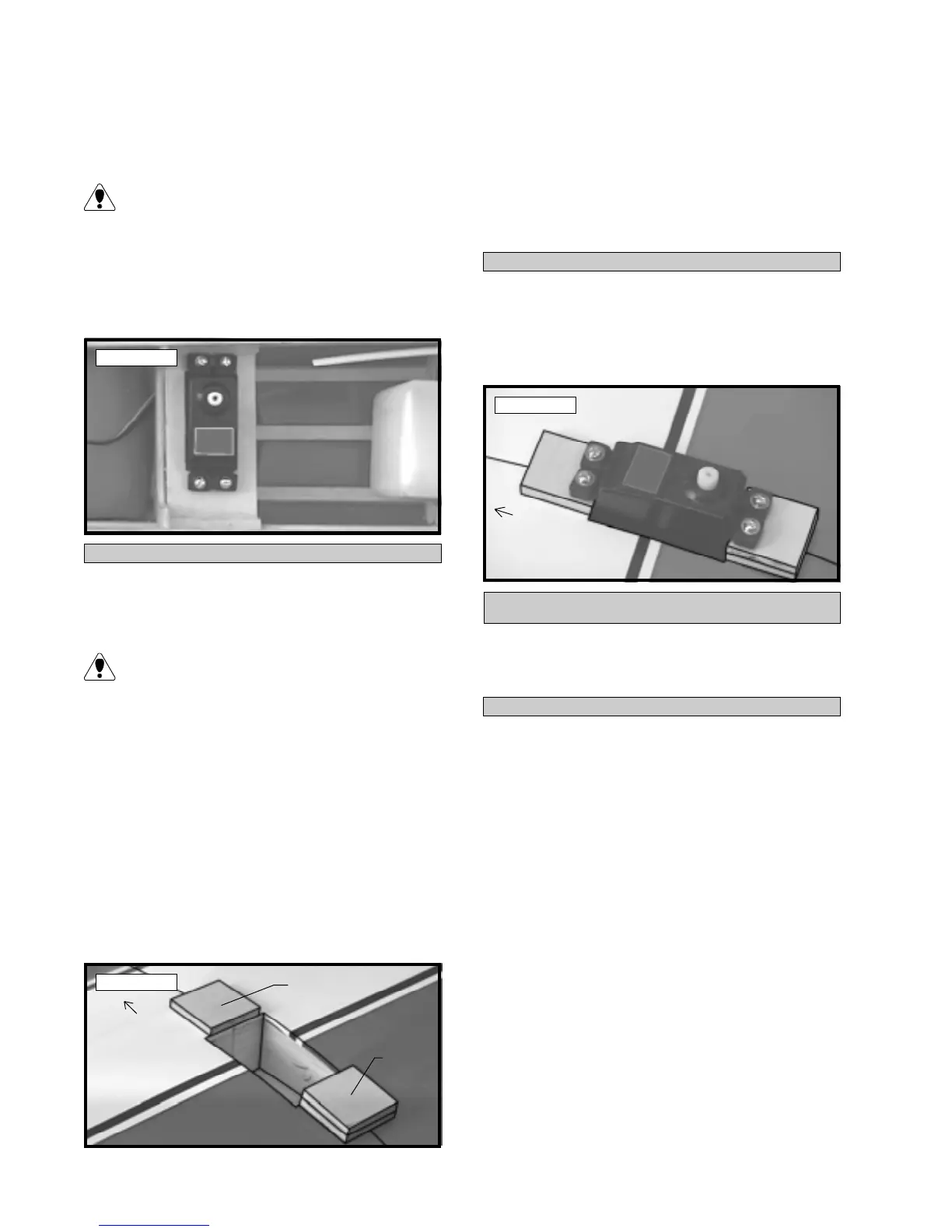

q 6) Install the throttle servo using the wood

screws provided with your radio system. Drill 1/16”

pilot holes through the tray before installing the

screws. This will help prevent the wood from split-

ting. See photo # 31 below.

Photo # 31

INSTALLING THE AILERON SERVO PLATES

q 7) Test fit the aileron servo into the prebuilt servo

box in the bottom side of the wing. The output shaft

should point towards the trailing edge of the wing.

Because the size of servos differ, you may need

to adjust the size of the box opening. You may

also need to use a modeling knife and cut a groove in

one end of the box to allow room for the servo wire to

fit without kinking.

q 8) Remove the servo. Using Kwik Bond Thick

C/A, laminate two of the aileron servo mounting plates

W-24 together, making sure all four edges are flush.

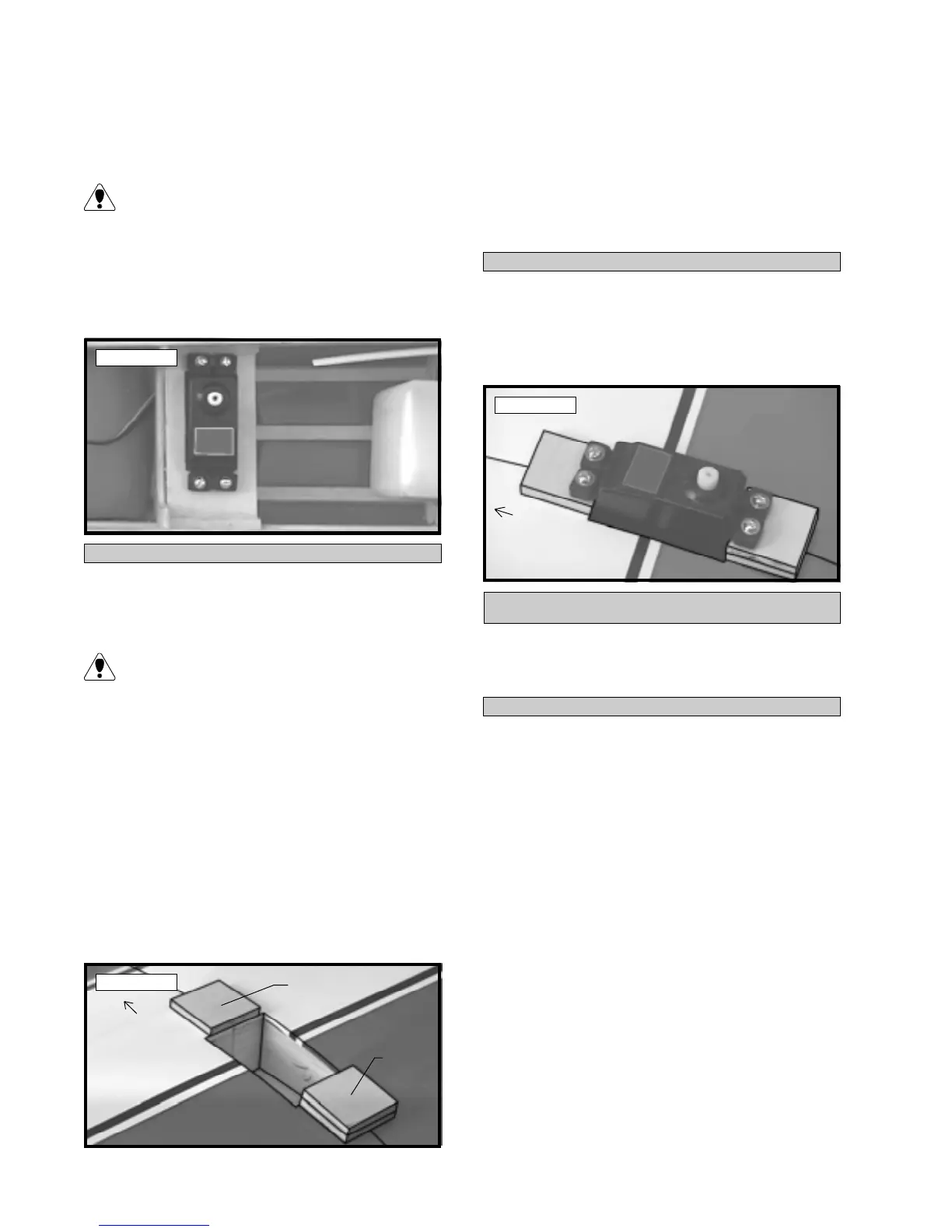

q 9) Position the servo mounting plates onto the

wing. The single plate goes at the front of the servo

opening and the laminated plate goes at the rear of

the opening. Both plates should be centered from

side to side and the inside edges should be even with

the servo opening. See photo # 32 below.

Photo # 32

q 10) Hold the two plates in position and trace

around them using a pen. Remove the plates and us-

ing a modeling knife, remove the covering from just

inside the lines.

q 11) Mix a small amount of Kwik Bond 5 Minute

Epoxy and glue the plates in place. Allow the epoxy

to cure completely.

INSTALLING THE AILERON SERVO

q 12) Install the aileron servo using the wood

screws provided with your radio system. Drill 1/16”

pilot holes through the plates before installing the

screws. This will help prevent the wood from split-

ting. See photo # 33 below.

Photo # 33

PARTS REQUIRED

q {1} 1.5mm x 45mm Threaded Wire

q {1} Nylon Clevis w/1.5mm I.D. Hole

THROTTLE CONNECTION

INSTALLING THE THROTTLE CLEVIS

q 1) With the servos plugged into the receiver, turn

on the radio system. Check to ensure that the throttle

servo output shaft is moving in the correct direction.

It should move clockwise when you advance the

throttle stick.

q 2) Position the throttle stick and the throttle trim

at their lowest positions. Thread the 1.5mm x 45mm

thread wire into the nylon throttle pushrod that was

installed previously. Thread the wire in about 5/16”.

q 3) While holding the wire with pliers, to pre-

vent it from turning, thread the nylon clevis onto the

end of the wire. Thread the clevis on about 5/16”.

q 4) Manually push the carburetor barrel fully

closed. Locate a servo arm and remove all but one of

the arms. Angle the servo arm back about 30º from

center and attach it to the servo. The arm should face

the right side of the airplane. With the carburetor

barrel fully closed, snap the clevis into the outer

W-24

W-24 (x2)

Front

Front

Loading...

Loading...