15

q 9) Slide the fuel tank into the fuel tank com-

partment in the front of the airplane. The top of the

tank should face the top of the fuselage and rest just

up against it and the stopper assembly should engage

the predrilled hole in the firewall. The tank should

be pushed as far forward as possible. This will pre-

vent the wing from interfering with the back of the

tank when the wing is mounted.

q 10) Secure the fuel tank in place using several

pieces of foam rubber. Seal the gaps between the

stopper asssembly and the firewall using silicon

sealer. Be careful not to get any silicon sealer inside

the aluminum tubes.

FUEL TANK INSTALLATION

PARTS REQUIRED

q {1} 4mm x 200mm Nylon Pushrod

q {1} 1.5mm x 52mm Threaded Wire w/Z-Bend

THROTTLE LINKAGE

INSTALLING THE THROTTLE LINKAGE

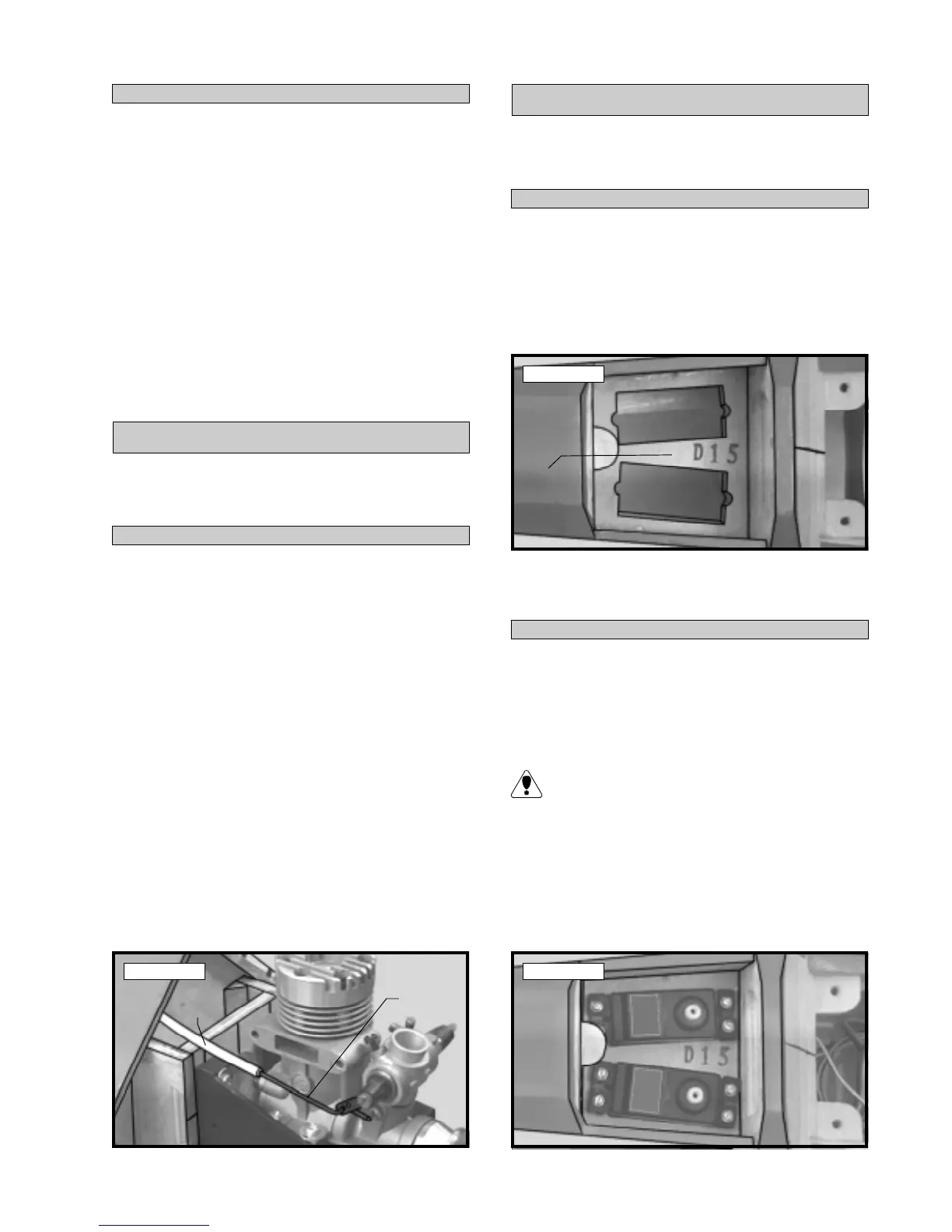

q 1) Thread the 1.5mm x 52mm threaded wire into

one end of the 4mm x 200mm nylon pushrod. Thread

the wire about 5/16” into the pushrod.

q 2) Using a modeling knife, cut off the excess

throttle pushrod housing inside the fuselage. Leave

about 1/4” extending beyond the front bulkhead.

q 3) Slide the plain end of the nylon pushrod

wire through the preinstalled pushrod housing in

the firewall. Remove the throttle arm from the car-

buretor and attach the Z-bend in the wire to the outer

hole in the arm.

q 4) Reattach the throttle arm to the carburetor and

use a pair of pliers to make small bends in the wire, if

necessary, so the pushrod does not bind when the car-

buretor is moved from the idle to the full throttle po-

sition. See photo # 28 below.

Photo # 28

PARTS REQUIRED

q {1} Fuselage Servo Tray D-15

q {3} Aileron Servo Mounting Plates W-24

SERVO INSTALLATION

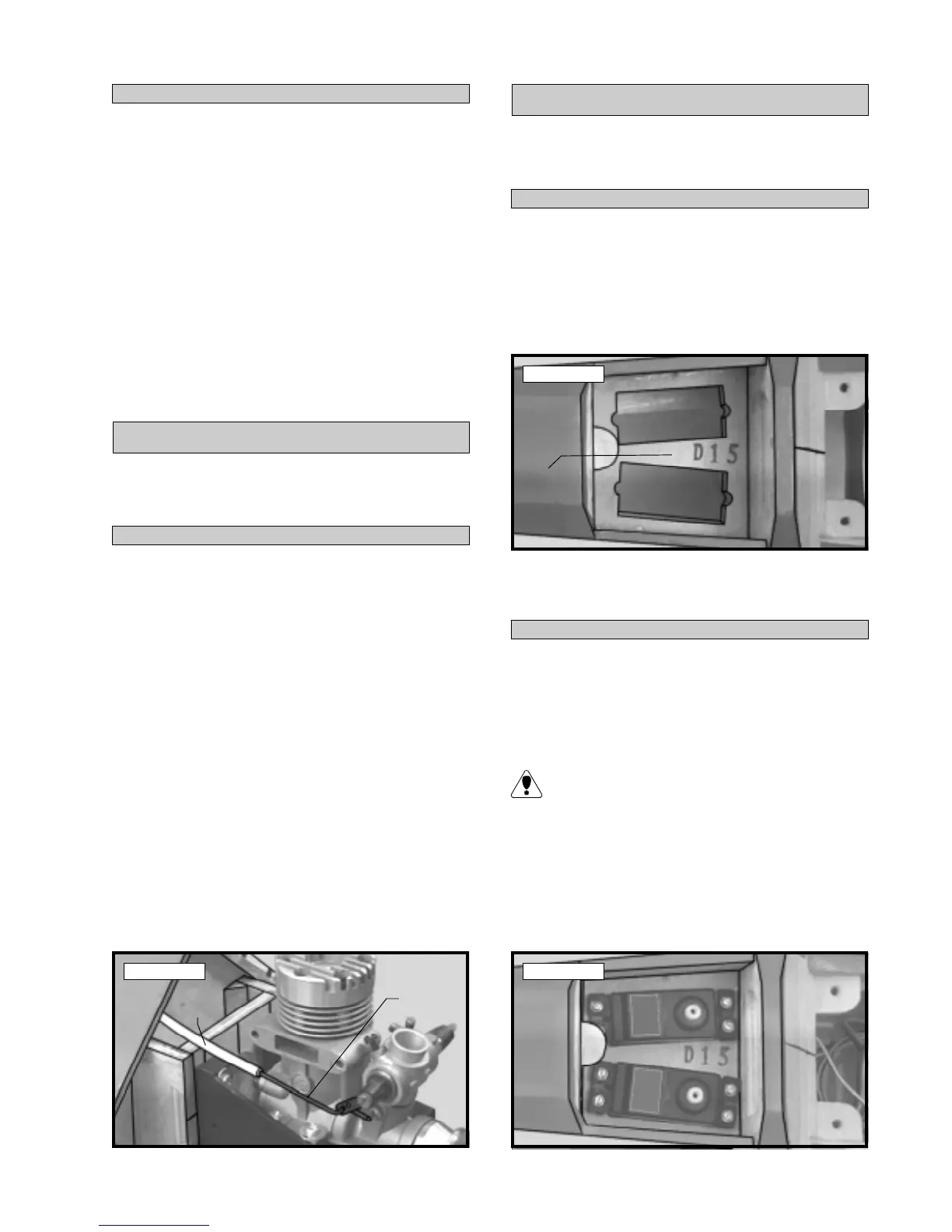

INSTALLING THE FUSELAGE SERVO TRAY

Photo # 29

q 2) When satisfied with the fit, remove the tray

and mix up a generous amount of Kwik Bond 5 Minute

Epoxy and glue the tray in place.

q 1) Remove the precovered hatch from the bot-

tom of the fuselage, just behind the wing saddle. Trial

fit the servo tray D-15 in position inside the fuselage.

The tray should rest on top of the preinstalled balsa

stringers glued to the fuselage sides. The front edge

of the tray should be pushed firmly against the rear

bulkhead. See photo # 29 below.

q 3) Install the rubber grommets and brass collets

provided with your radio system onto four servos. Test

fit two of the servos into the two precut servo holes in

the fuselage servo tray D-15. These will be the el-

evator and rudder servos.

Because the size of servos differ, you may need

to adjust the size of the precut openings.

q 4) Install the elevator and rudder servos using

the wood screws provided with your radio system.

Drill 1/16” pilot holes through the tray before install-

ing the screws. This will help prevent the wood from

splitting. Install the servos with the output shafts fac-

ing the front of the airplane. See photo # 30 below.

INSTALLING THE FUSELAGE SERVOS

Photo # 30

Nylon

Pushrod

Pushrod

Wire

Servo

Tray

Loading...

Loading...