14

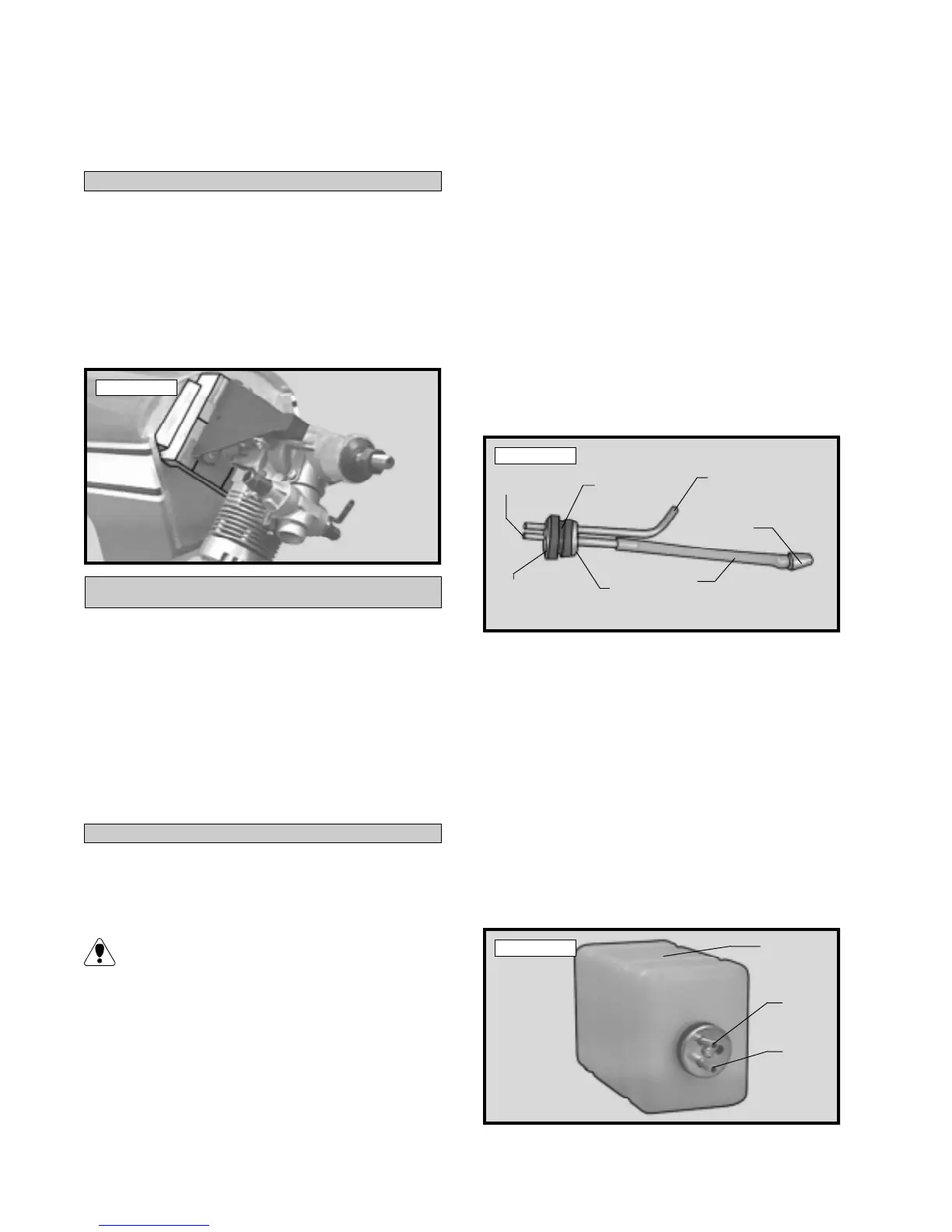

q 9) Hold the motor mount assembly up to the

firewall and double check that the four intersecting

lines line up with the four predrilled holes in the

motor mount.

q 10) Using a 1/8” drill bit, drill the four mounting

holes through the firewall for the motor mount.

q 11) Mount the motor mount assembly to the fire-

wall using the four 3mm x 20mm machine screws,

eight 3mm flat washers and four 3mm nylon insert

nuts. Tighten the screws and nuts completely. See

photo # 25 below.

MOUNTING THE ENGINE TO FIREWALL

Photo # 25

PARTS REQUIRED

q {1} 190cc Molded Plastic Fuel Tank

q {1} Rubber Stopper

q {1} 70mm Silicon Fuel Line

q {1} Weighted Clunk

q {1} 70mm Aluminum Tube

q {1} 40mm Aluminum Tube

q {1} 30mm Aluminum Tube

q {1} 15mm Diameter Rear Squash Plate

q {1} 20mm Diameter Front Squash Plate

q {1} 3mm x 20mm Machine Screw

FUEL TANK

ASSEMBLE THE FUEL TANK

q 1) The fuel tank assembly incudes 3 different

length aluminum tubes. Discard the shortest of the

three tubes. It will not be used.

The 40mm length tube is used for the fuel

line pickup and the 70mm tube is used for

the vent/pressure line.

q 2) Using 220 grit sandpaper carefully smooth

each end of the two tubes. This will prevent the fuel

line from being cut.

q 3) Push the two aluminum tubes through the rub-

ber stopper until 1/2” protrudes from the front of the

stopper. Slide the 20mm diameter front squash plate

over the tubes at the front of the stopper and slide the

15mm diameter rear squash plate over the tubes at

the rear of the stopper. Insert the 3mm x 20mm ma-

chine screw into the center hole in the front squash

plate, then screw it through the stopper and into the

rear squash plate. Do not completely tighten the screw

at this time.

q 4) Carefully bend the longer of the two tubes

up at a 45º angle. This tube is the vent tube. When

the stopper assembly is installed in the tank, the top

of the vent tube should rest just below the top surface

of the tank. It should not touch the top of the tank.

q 5) Slide the silicon fuel tubing, with the

weighted pickup attached to one end, onto the fuel

pickup tube. See photo # 26 below.

Photo # 26

q 6) Test fit the stopper assembly into the tank. It

may be necessary to remove some of the flashing

around the tank opening using a modeling knife. If

flashing is present, make sure none falls into the tank.

q 7) With the stopper assembly in place, the

weighted pickup should rest about 3/8” away from

the rear of the tank and move freely inside the tank.

q 8) When satisfied with the alignment of the stop-

per assembly tighten the 3mm x 20mm machine screw

until the rubber stopper expands and seals the tank

opening. Do not overtighten the assembly as this

could cause the tank to split. See photo # 27 below.

Photo # 27

Vent Tube

Weighted

Pickup

Fuel

Tubing

Rear

Squash

Plate

Rubber

Stopper

Front

Squash

Plate

Fuel Pickup

Tube

Vent

Tube

Fuel

Pickup

Tube

Top of

Tank

Loading...

Loading...